Paper supplying device

A paper-feeding and process device technology, applied in the field of paper-feeding devices, can solve problems such as complex structures of paper-feeding devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A paper feeding device according to a preferred embodiment of the present invention will be described below with reference to related drawings.

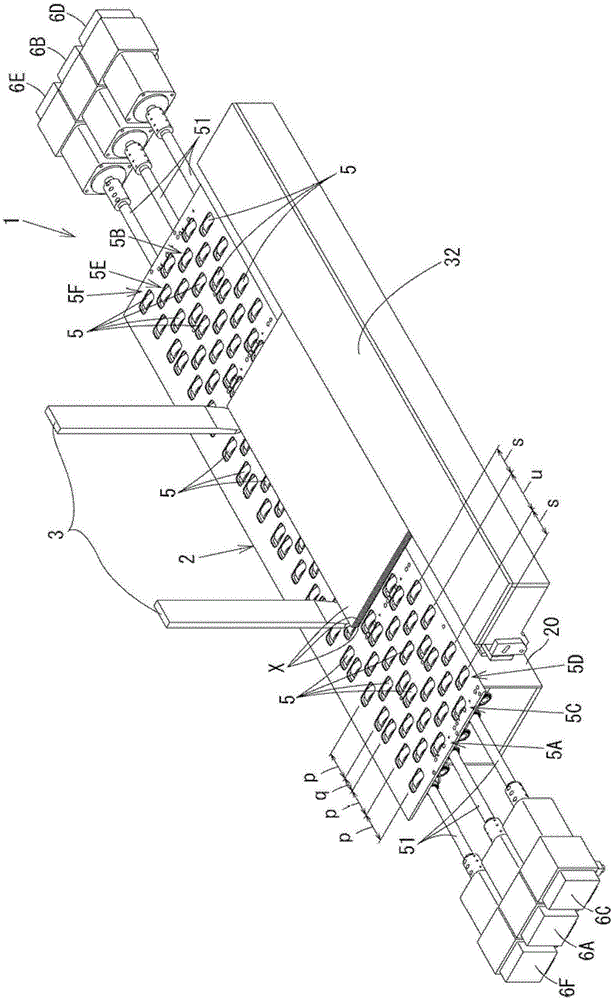

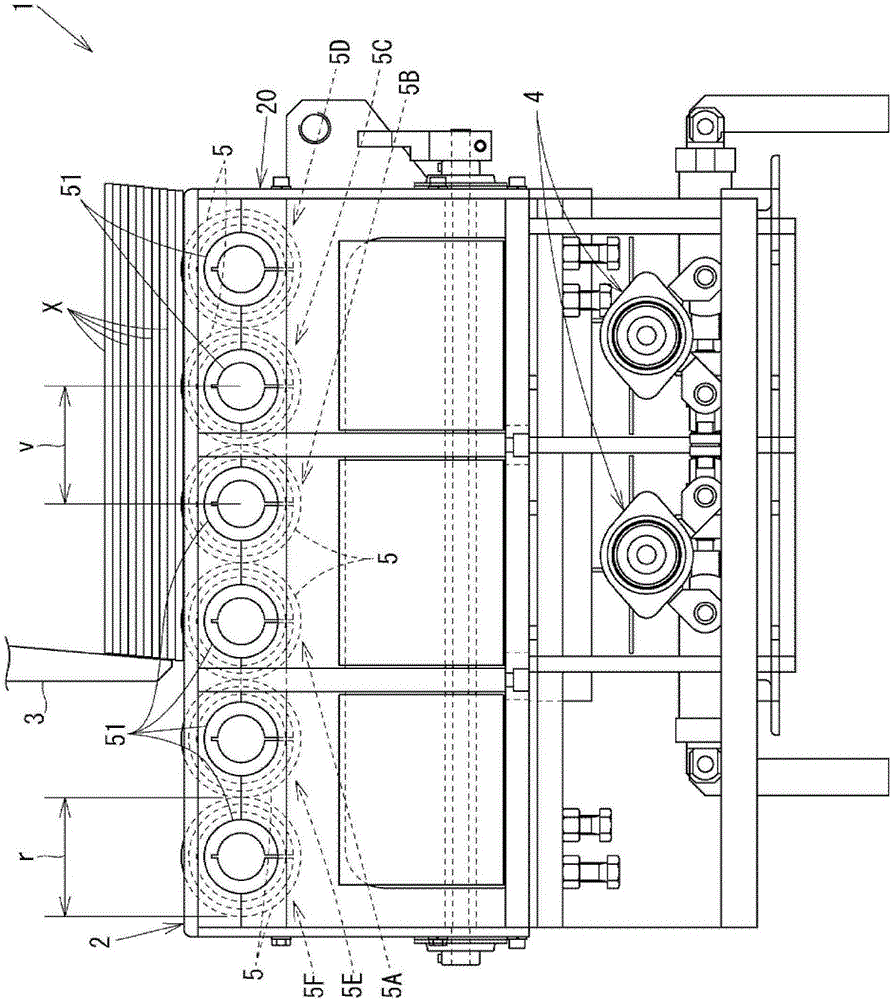

[0030] first, figure 1 It is a perspective view of the overall structure of the paper feeding device according to the first embodiment of the present invention, figure 2 for viewing from the side figure 1 Side view of the feeder shown.

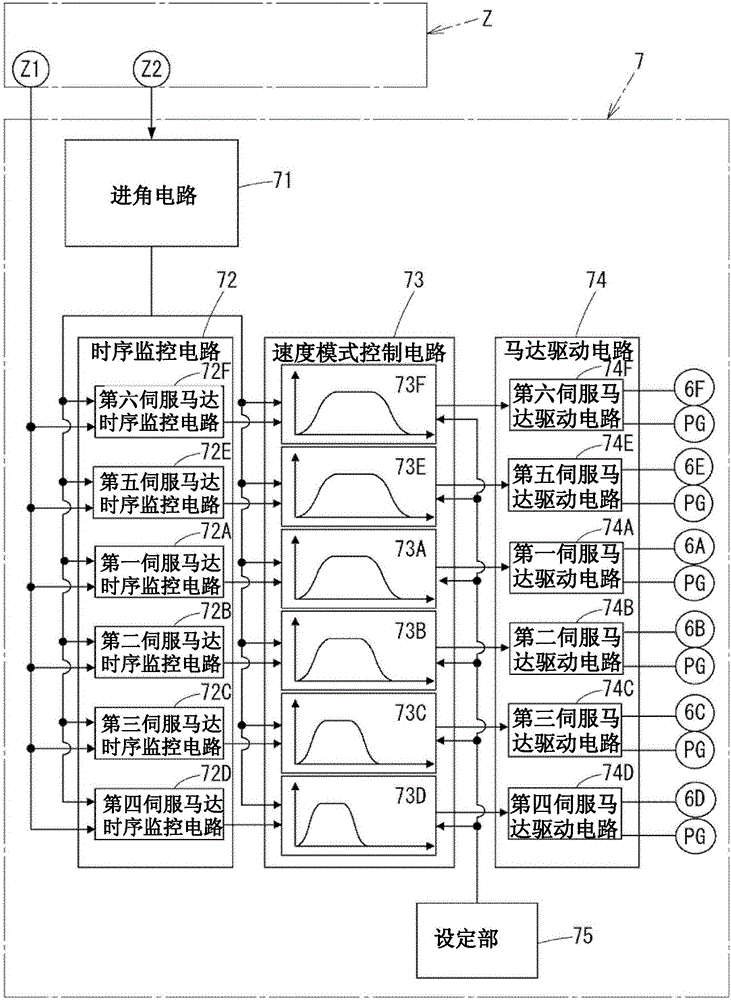

[0031] Such as figure 1 and figure 2 As shown, the paper feeding device 1 is used to convey the cardboard one by one to the printing device Z (post-processing device) of the carton forming machine (not shown) used in the subsequent process, and the paper feeding device 1 includes a paper feeding table 2 as Cardboard corrugated cardboards X, X... are stacked on the paper feeding table 2 . This paper feeding table 2 is arranged on the upper end of the casing 20 . A left and right pair of guide plates 3, 3 are arranged at the rear position of the paper feeding table 2, and there is a gap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com