Inertial air circulation valves for compressors of internal combustion engines

A technology for air circulation valves and compressors, applied to internal combustion piston engines, combustion engines, machines/engines, etc., can solve problems such as small thermal load capacity, expensive plastics, and difficult disassembly, so as to reduce fouling, avoid losses, cost reduction effect

Active Publication Date: 2019-10-01

PIERBURG GMBH & CO KG NEUSS

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Although this simplifies the installation, it has the result that gas can penetrate from the housing interior space into the laterally connected channels through the gaps between the parts

This air flow can also lead to the infiltration of contaminated gases into the gap, which leads to agglomeration, which obviously makes the disassembly of the valve difficult.

In addition, the plastics used are also prone to increased fouling due to their lower thermal load capacity

Alternatively, very expensive plastics must be used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

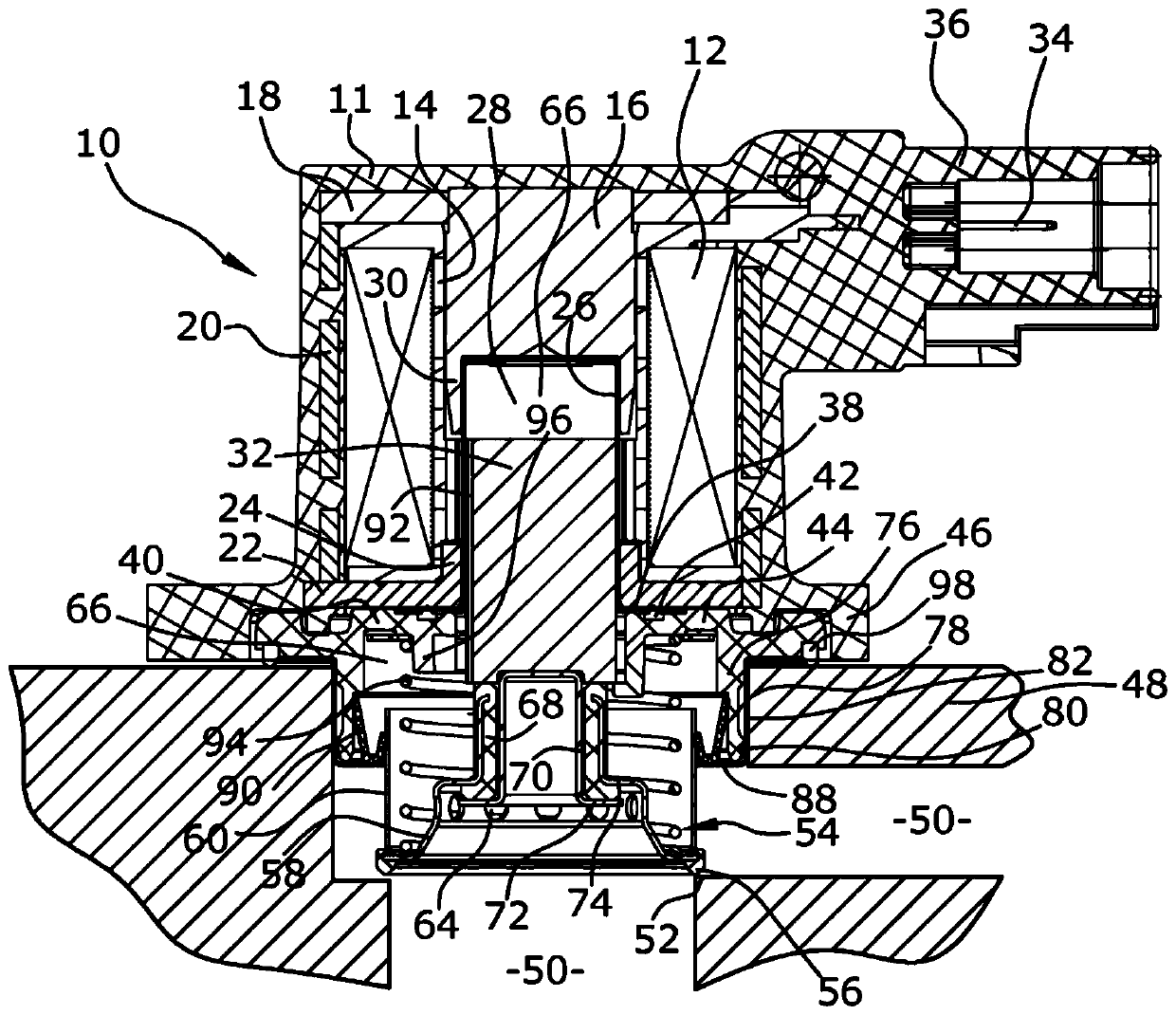

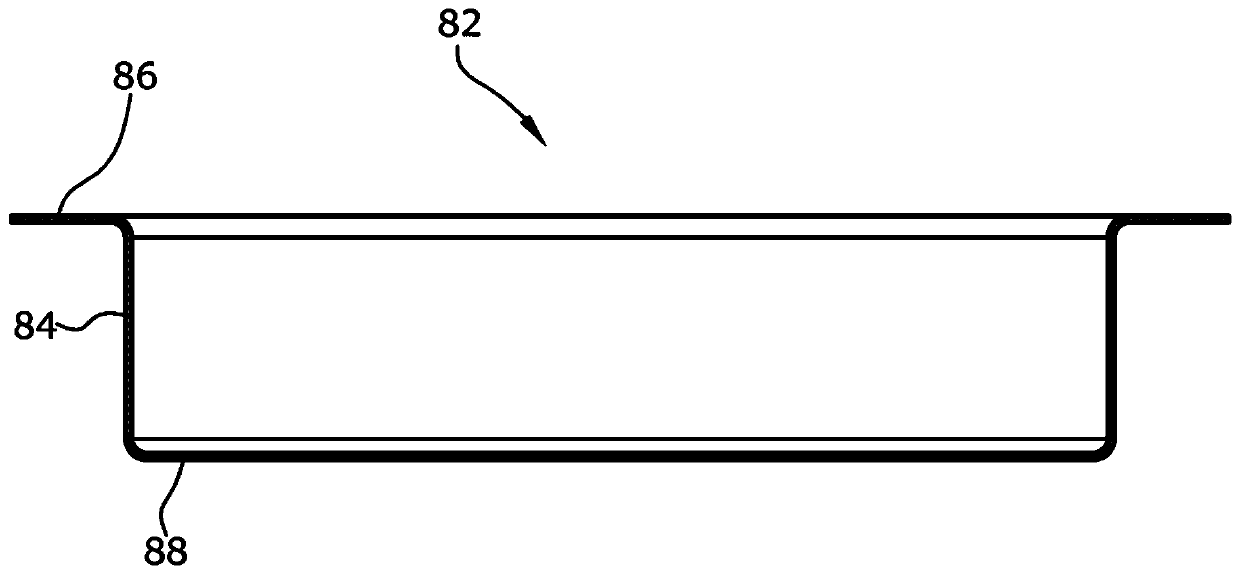

The invention relates to an inertial air circulation valve for a compressor of an internal combustion engine, comprising a fluid housing (48), an electromagnetic actuator (10), a regulating body (54), a housing interior (66), the Openings ( 64 ) in the regulating body ( 54 ), valve housings ( 11 , 40 ) and radial sealing rings ( 90 ), in which passages ( 50 ) are formed in the fluid housing, the regulating body ( 54 ) by means of an actuator ( 10 ) The flow cross-section of the channel ( 50 ) is movable and adjustable by means of an adjusting body, in the housing interior ( 66 ), the armature ( 32 ) of the electromagnetic actuator ( 10 ) connected to the adjusting body ( 54 ) Movable, opening (64) in the adjusting body (54), through the opening (64) of the housing interior space (66) and the part of the channel (50) that rests axially on the adjusting body (54) in the fluid Fluidly connected in the housing (48), the valve housing (11, 40) radially surrounds the electromagnetic actuator (10) and the axially extending section of the regulating body (54), via radial sealing rings (90), The housing interior ( 66 ) is sealed against the part of the channel ( 50 ) which rests radially on the adjusting body ( 54 ) and the radial sealing ring ( 90 ) is supported axially in the radial direction of the bearing ring ( 82 ). On the inwardly directed annular plate ( 88 ), the bearing ring rests radially from the outside with a cylindrical wall ( 84 ) against the housing wall ( 76 ) of the valve housing ( 11 , 40 ). In order to obtain a cost-effectively producible valve with increased tightness between the two channel parts to be separated, it is proposed here that the radial sealing ring ( 90 ) abuts the valve housing ( 11 ) radially outwards , 40) on the housing wall (76).

Description

technical field The invention relates to an inertial air circulation valve for a compressor of an internal combustion engine, which has a flow housing, an electromagnetic actuator, an adjusting body, an interior space of the housing, an opening in the adjusting body, a valve housing, a radial sealing ring, a channel is formed in the flow housing, the adjusting body is movable by means of an actuator and the flow cross-section of the channel can be adjusted by means of the adjusting body, in the housing interior, the The armature of the electromagnetic actuator, which is connected to the adjusting body, is movable, and through the opening, the housing interior is fluidically connected to the part of the channel which rests axially on the adjusting body in the flow housing, so that The valve housing radially surrounds the electromagnetic actuator and the axially extending section of the adjusting body, and the inner space of the housing rests against the adjusting body radially r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F02B37/16

CPCF16K27/029F16K1/36F16K1/46F16K31/0655F16K31/0686F02B37/16Y02T10/12F16K31/0644

Inventor M.伦克O.保罗

Owner PIERBURG GMBH & CO KG NEUSS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com