Harvesting and vanning manipulator

A technology of manipulators and conveyors, which is applied in the direction of manipulators, harvesters, packaging machines, etc., can solve the problems of missing the crop growth and harvesting cycle, affecting the overall efficiency, and difficult to maintain quality and quantity, so as to realize automatic operation, improve overall efficiency, and respond quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

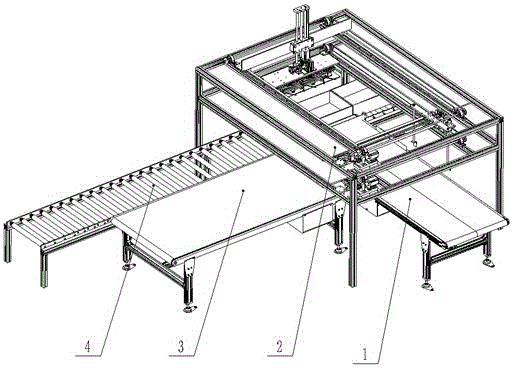

[0031] Example. Harvesting boxing manipulator, constituted as Figure 1-9 As shown, it includes a mature vegetable input machine 1, a harvesting manipulator 2 is arranged above the ripe vegetable input machine 1, and an empty dish output machine 3 and a harvest box conveyor 4 are arranged on the side of the harvesting manipulator 2.

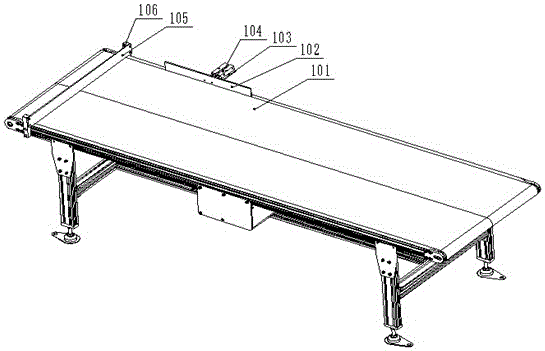

[0032] Described ripe vegetable input machine 1 comprises conveyor 101, and conveyor 101 is provided with conveyor side baffle 102, and conveyor side baffle 102 is provided with conveyor side clamping cylinder 104 through conveyor cylinder mounting block 103, conveys The end of the machine 101 is provided with a baffle 105 through a baffle strip 106 .

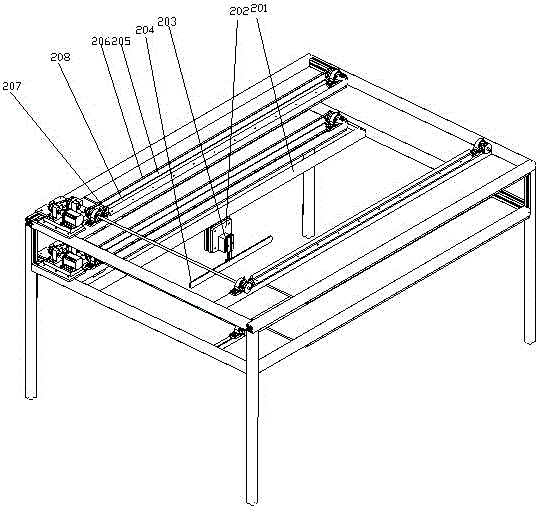

[0033] Described harvesting manipulator 2 comprises the shelf of two layers, and the shelf of upper stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com