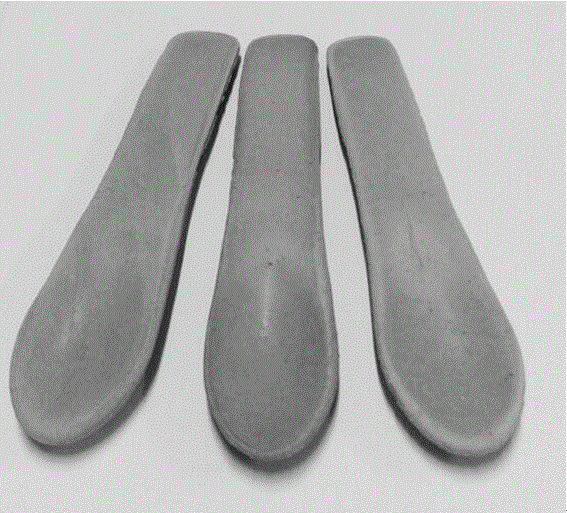

Edible spoon and making method thereof

A spoon and edible technology, applied in the field of edible spoon and its preparation, can solve the problems of low strength, high cost, short shelf life, etc., and achieve the effect of high strength, good practicability, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Crush the grain into powder and pass through 200~250 sieves to obtain grain powder;

[0032] (2) Prepare 80 parts of grain powder, 20 parts of water, and 1 part of edible oil by weight;

[0033] (3) Add the water prepared in step (2) to the grain powder prepared in step (2), mix and stir, add edible oil, and blend until it forms a dough. When blending, the ambient temperature is controlled at 18~25°C, and the dough temperature is controlled at 20~35℃; after that, let stand;

[0034] (4) Roll the product obtained in step (3), and carry out a standing treatment at 18-25°C; then put it into a mold;

[0035] (5) Preheat the product obtained in step (4) at 180°C; then bake for 15 minutes at a surface fire of 190°C and a primer fire of 190°C;

[0036] (6) cooling the result of step (5) to obtain;

[0037] The grain is composed of two parts, A and B, the A is sorghum; the B is sweet potato; the mass ratio of A and B is 3:1.

Embodiment 2

[0039] (1) Crush the grain into powder and pass through 200~250 sieves to obtain grain powder;

[0040] (2) By weight, prepare 120 parts of grain powder, 22 parts of water, and 3 parts of edible oil;

[0041] (3) Add the water prepared in step (2) to the grain powder prepared in step (2), mix and stir, add edible oil, and blend until it forms a dough. When blending, the ambient temperature is controlled at 18~25°C, and the dough temperature is controlled at 20~35℃; after that, let stand;

[0042] (4) Roll the product obtained in step (3), and carry out a standing treatment at 18-25°C; then put it into a mold;

[0043] (5) Preheat the product obtained in step (4) at 180°C; then bake for 35 minutes at a surface fire of 170°C and a primer fire of 170°C;

[0044] (6) cooling the result of step (5) to obtain;

[0045] The grain is composed of two parts, A and B, the A is glutinous rice; the B is potato; the mass ratio of A and B is 5:2.

Embodiment 3

[0047] (1) Crush the grain into powder and pass through 200~250 sieves to obtain grain powder;

[0048] (2) Prepare 100 parts of grain powder, 21.5 parts of water, and 1.5 parts of edible oil by weight;

[0049] (3) Add the water prepared in step (2) to the grain powder prepared in step (2), mix and stir, add edible oil, and blend until it forms a dough. When blending, the ambient temperature is controlled at 18~25°C, and the dough temperature is controlled at 20~35℃; after that, let stand;

[0050] (4) Roll the product obtained in step (3), and carry out a standing treatment at 18-25°C; then put it into a mold;

[0051] (5) Preheat the product obtained in step (4) at 180°C; then bake for 30 minutes at a surface fire of 180°C and a primer fire of 180°C;

[0052] (6) cooling the result of step (5) to obtain;

[0053] The grain is composed of two parts, A and B, the A is rice; the B is corn; the mass ratio of A and B is 4:1.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com