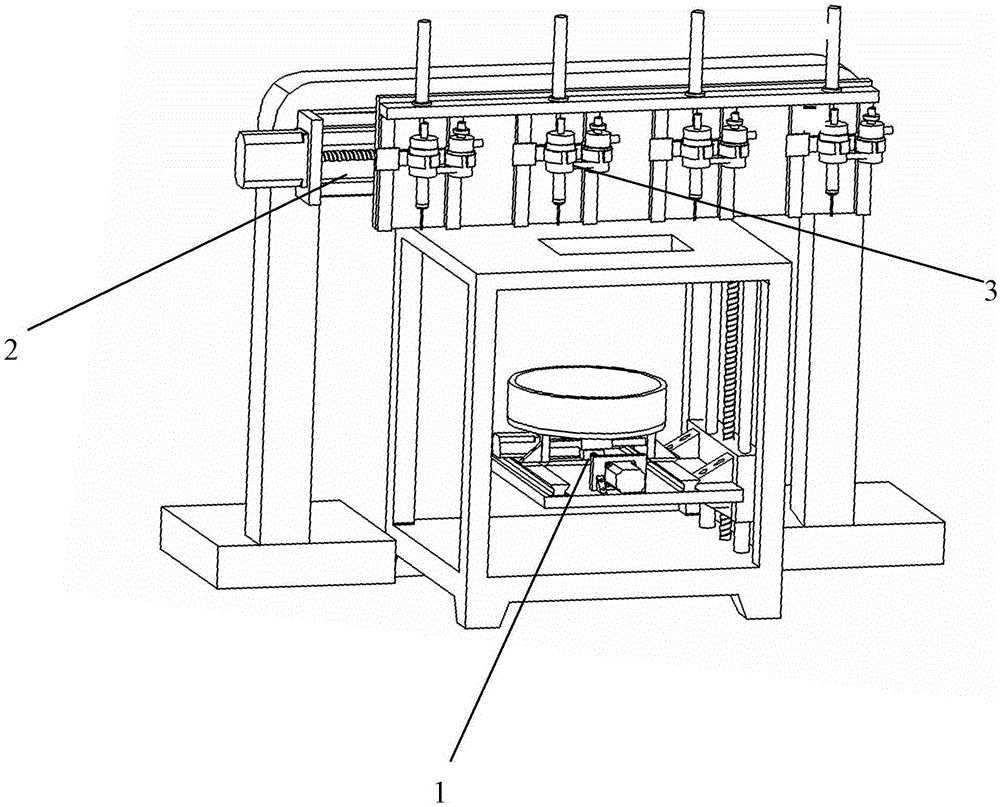

High-precision ultrasonic anti-blocking multi-cell biological additive manufacturing method and device

A kind of additive manufacturing and multi-cell technology, applied in additive processing, medical science, prosthesis, etc., can solve the problems of inaccurate cell positioning, low printing efficiency, nozzle clogging, etc., to improve survival rate, facilitate clamping, The effect of reducing the probability of congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

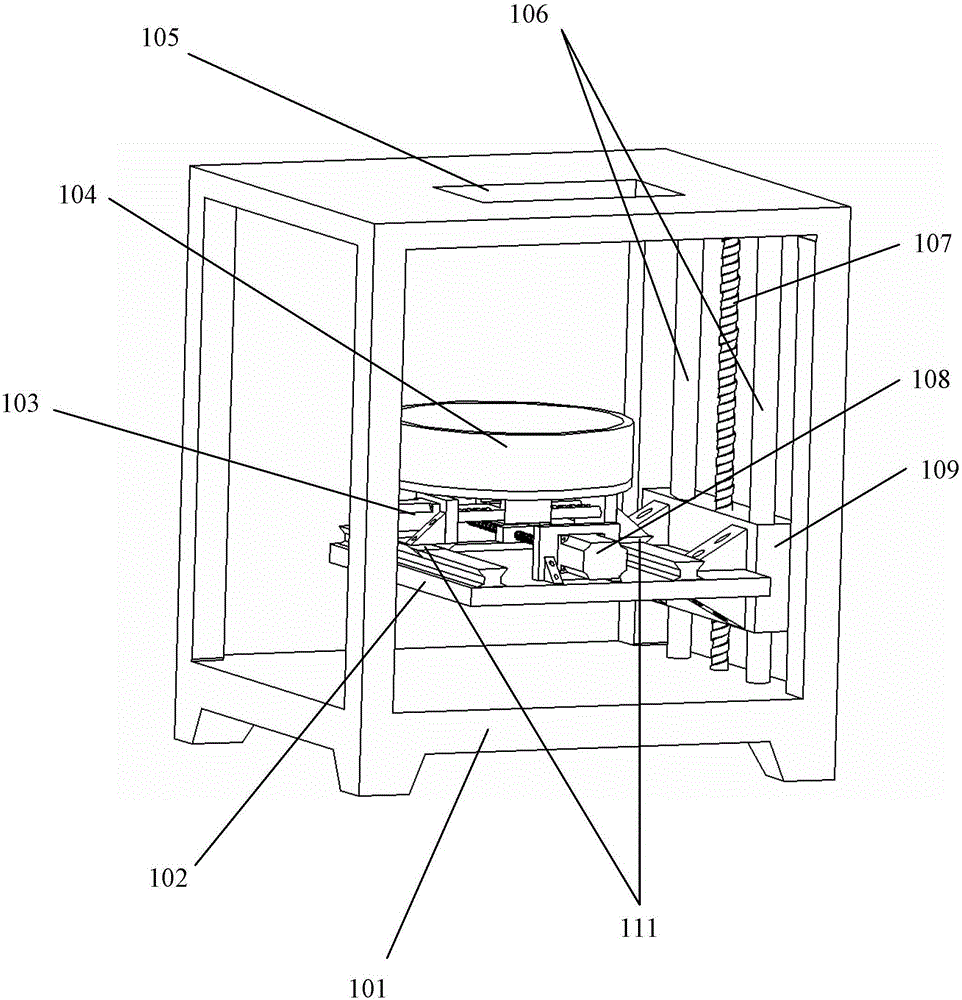

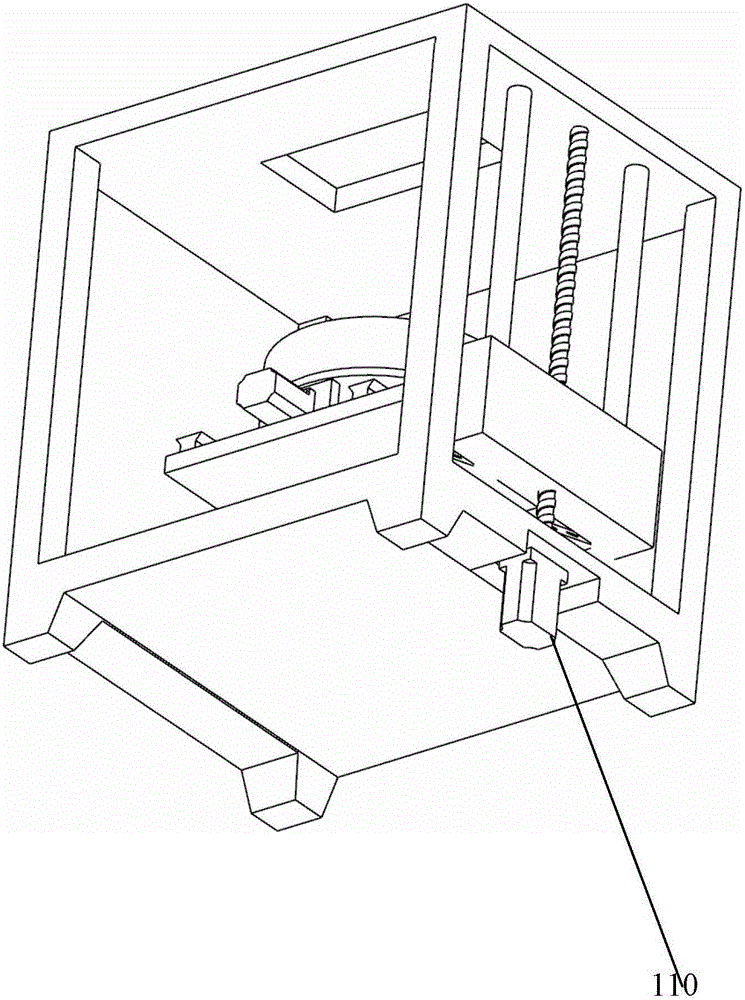

Embodiment Construction

[0037] Include the following steps:

[0038] 1) Before printing, put the printing device into the disinfection cabinet or sterilization box for 15 minutes, and finally put it into the sterile test room or the sterile test box to wait for printing;

[0039] 2) Inject the biological solution containing various cells into the storage chamber connected to the nozzle one, and apply a strength of 20mw / cm to the nozzle 2 , ultrasonic frequency 200KHz, open the nozzle-piezoelectric drive device and the storage chamber-pneumatic device, the piezoelectric drive device and the ultrasonic wave form a composite driving force, and the droplet ejection efficiency is higher;

[0040] 3) The high-strength composite hydrogel is injected into the second storage chamber connected to the special nozzle for printing blood vessels, and the pneumatic device of the second storage chamber is turned on, waiting for printing;

[0041] 4) Place a printed polyethylene (PE) organ base with 80% porosity on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com