Efficient preparation equipment of microbial starter culture for treating municipal sludge

A technology of microbial fermentation agent and municipal sludge, which is applied in the direction of grain treatment, mixed material pretreatment, chemical/physical process, etc., to achieve humanized design, good mixing effect and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

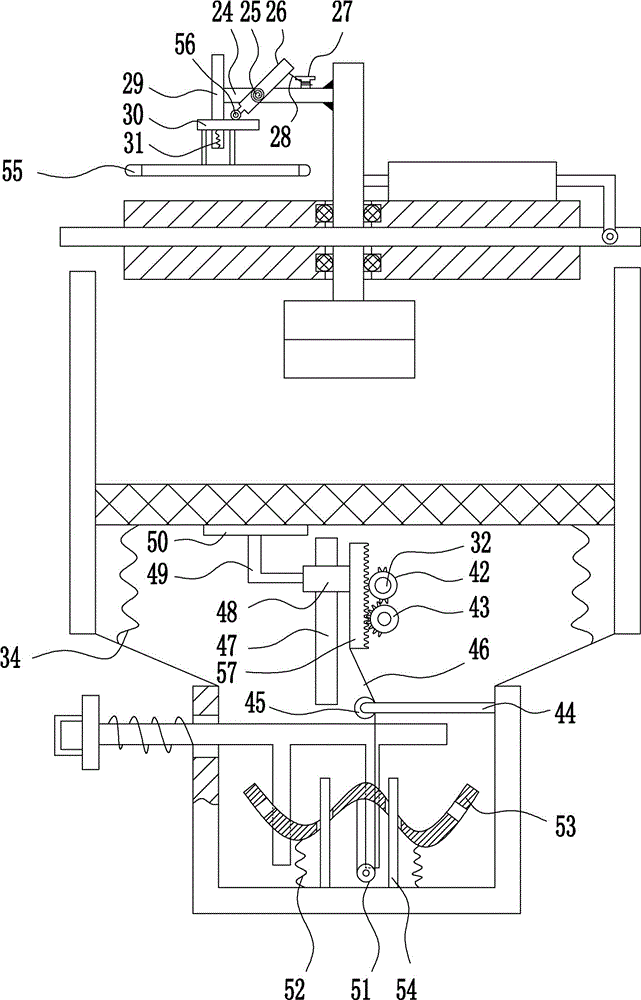

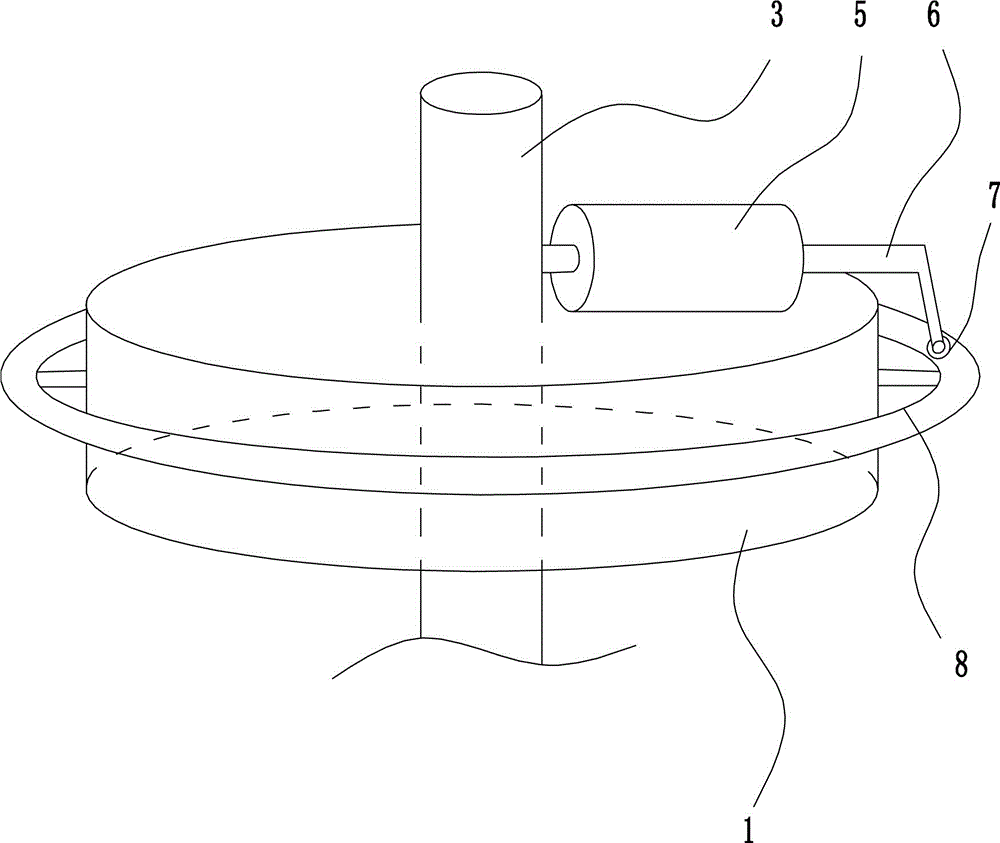

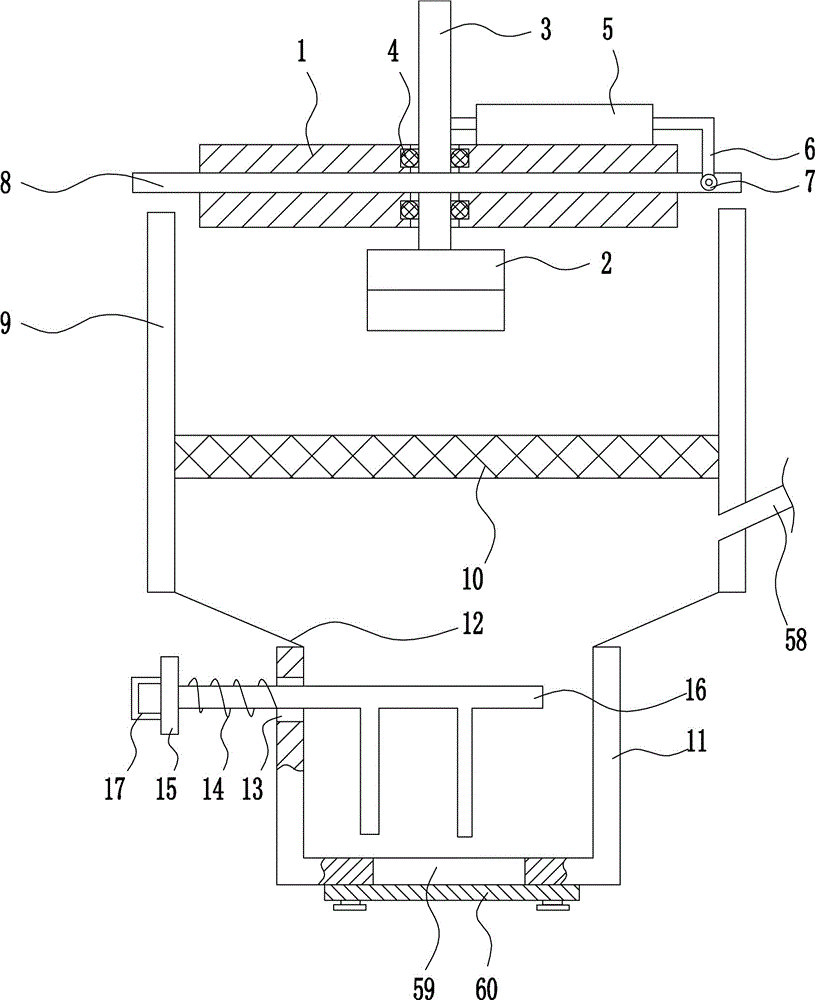

[0028] A kind of high-efficiency preparation equipment for treating municipal sludge with microbial fermentation agent, such as Figure 1-5As shown, it includes a frame, a grinding disc 1, a gear motor 2, a first rotating rod 3, an O-shaped sealing ring 4, a grinding stone 5, a first connecting rod 6, a first roller 7, a circular slide rail 8, and a filter box 9. Filter screen 10, mixing box 11, conical material guide plate 12, first spring 14, moving plate 15, stirring rod 16, handle 17, liquid inlet pipe 58 and baffle plate 60, and a grinding disc is welded on the frame through the bracket 1. There is a decelerating motor 2 at the bottom of the milling disc 1, and the decelerating motor 2 is installed on the frame through bolt connection. hole, the first rotating rod 3 passes through the through hole opened in the center of the grinding disc 1, and the through hole is provided with an O seal ring 4, and the first connecting rod 6 is welded on the top of the first rotating ro...

Embodiment 2

[0036] A kind of high-efficiency preparation equipment for treating municipal sludge with microbial fermentation agent, such as Figure 1-5 As shown, it includes a frame, a grinding disc 1, a gear motor 2, a first rotating rod 3, an O-shaped sealing ring 4, a grinding stone 5, a first connecting rod 6, a first roller 7, a circular slide rail 8, and a filter box 9. Filter screen 10, mixing box 11, conical material guide plate 12, first spring 14, moving plate 15, stirring rod 16, handle 17, liquid inlet pipe 58 and baffle plate 60, and a grinding disc is welded on the frame through the bracket 1. There is a decelerating motor 2 at the bottom of the milling disc 1, and the decelerating motor 2 is installed on the frame through bolt connection. hole, the first rotating rod 3 passes through the through hole opened in the center of the grinding disc 1, and the through hole is provided with an O seal ring 4, and the first connecting rod 6 is welded on the top of the first rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com