Fluorspar lump ore and particle ore reselection process

A particle and stone technology, which is applied in the field of fluorite lump ore and particle ore gravity separation, can solve the problems of difficult large-scale production, large randomness, and large labor force, so as to reduce production and processing costs, improve recycling rate, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

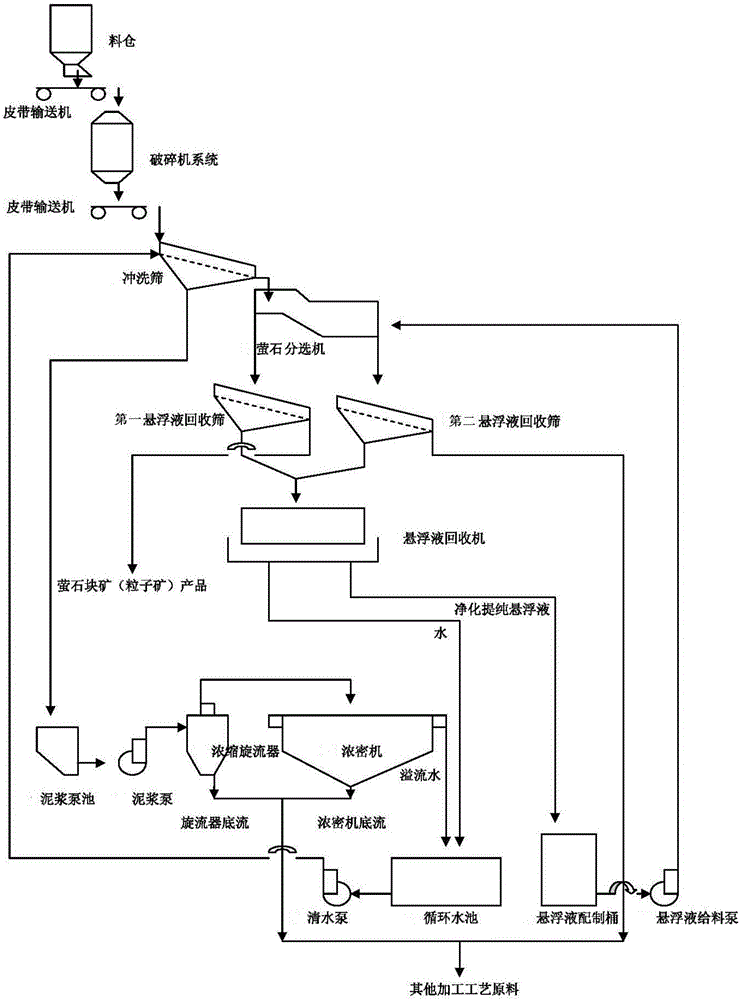

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The gravity separation process of fluorite lump ore and particle ore includes the following steps, 1) transporting fluorite ore to the crusher system for crushing and grading, and obtaining lump ore and particle ore with a particle size of less than 70 mm; 2) lump ore and particle ore Transported to the flushing screen, the clean water circulation system supplies water to clean the lump ore and particle ore. After cleaning, clean lump ore and particle ore are obtained and separated to produce cleaning mud. The cleaning mud enters the mud recovery system; 3) clean The lump ore and particle ore are fed into the fluorite separator for sorting; 4) The lump ore and particle ore that sink to the bottom of the fluorite separator are scraped out by the scraper and enter the first suspension recovery screen, floating in the suspension liquid The lump ore and particle ore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap