Inclined corrugated combined rolling roller for rolling metal composite plate

A metal clad plate, oblique corrugation technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of roll shaft or roll sleeve damage, short life of roll shaft or roll sleeve, and increased roll changing frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The specific implementation of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but not to limit the present invention.

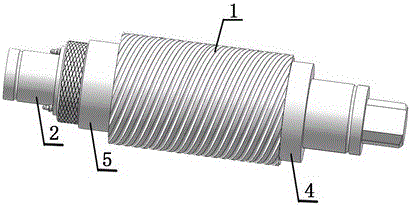

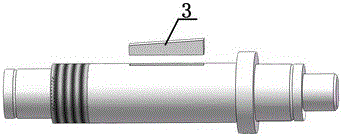

[0009] Such as figure 1 , 2 As shown, a combined roll for rolling oblique corrugated metal composite plates is composed of a roll shaft (1), a diagonal corrugated roll sleeve (2), a wedge key (3), and a hydraulic lock nut (5). (1), the wedge key (3) and the hydraulic lock nut (5) are made of No. 45 steel, and the oblique corrugated roller sleeve (2) is made of high-strength hard alloy steel 60GrMnMo, and the axial angle between the oblique corrugation and the roll The height of the corrugation is 1.3 times of the thickness of the doubler plate, and the width of the corrugation is 12 times of the height of the corrugation. The keyway on the surface has a slope matching the wedge key, and the circumferential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com