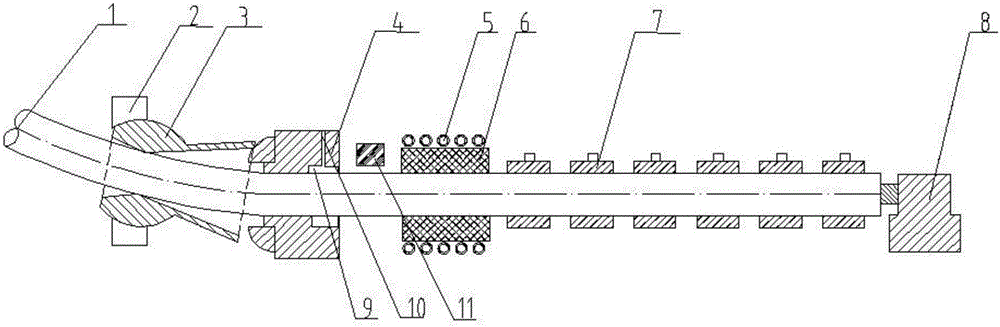

Aviation titanium alloy 3D free bend warm forming device and forming method

A technology of warm forming and titanium alloy, applied in metal processing, transportation and packaging, metal processing equipment, etc., can solve the problem of inability to achieve bending radius, and achieve the effect of important engineering application value, high production efficiency and obvious economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

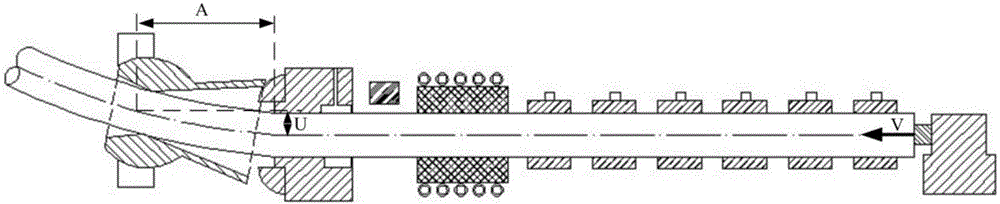

[0028] In the first step, the TC4 titanium alloy tube with a length of 250mm, a diameter of 20mm, and a wall thickness of 1mm is heated to 690°C in a heating furnace before forming a space bend;

[0029] The second step is to conduct a free bending test on the heated titanium alloy tube to obtain the bending radius R when the eccentricity is 1mm, 2mm, 3mm..., and draw the relationship curve between the eccentricity U and the bending radius R;

[0030] The third step is to analyze the process of the complex space elbow to be bent, and obtain the bending radius R to be bent 1 Eccentricity U at =65mm 1 =10mm and R 2 Eccentricity U at =80mm 2 = 8mm;

[0031] The fourth step, the U 1 =10mm, U 2 =8mm is substituted into the forming process analysis formula to obtain the forming process parameters for the complex space elbow to be bent;

[0032] The fifth step is to input the forming process parameters and the induction heating temperature of 690°C into the special control soft...

Embodiment 2

[0036] In the first step, the TC4 titanium alloy tube with a length of 150mm, a diameter of 15mm, and a wall thickness of 1mm is heated to 680°C in a heating furnace before forming a space bend;

[0037] The second step is to conduct a free bending test on the heated titanium alloy tube to obtain the bending radius R when the eccentricity is 1mm, 2mm, 3mm..., and draw the relationship curve between the eccentricity U and the bending radius R;

[0038] The third step is to analyze the process of the complex space elbow to be bent, and obtain the bending radius R to be bent 1 =Corresponding eccentricity U when 70mm 1 = 6mm, R 2 =Corresponding eccentricity U when 80mm 2 =5mm, R 3 Eccentricity U when =75mm 3 =6.4mm;

[0039] The fourth step, the U 1 = 6mm, U 2 =5mm, U 3 =6.4mm is substituted into the forming process analysis formula to obtain the forming process parameters for the complex space elbow to be bent;

[0040] The fifth step is to input the forming process para...

Embodiment 3

[0044] In the first step, the TC4 titanium alloy tube with a length of 300 mm, a diameter of 20 mm, and a wall thickness of 2 mm is heated to 700 ° C in a heating furnace before forming a space bend;

[0045]The second step is to conduct a free bending test on the heated titanium alloy tube to obtain the bending radius R when the eccentricity is 1mm, 2mm, 3mm..., and draw the relationship curve between the eccentricity U and the bending radius R;

[0046] The third step is to analyze the process of the complex space elbow to be bent, and obtain the bending radius R to be bent 1 =Corresponding eccentricity U when 80mm 1 = 8mm, R 2 =Corresponding eccentricity U when 90mm 2 = 7mm, R 3 Eccentricity U when =90mm 3 =6mm;

[0047] The fourth step, the U 1 =8mm, U 2 =7mm, U 3 =6mm is substituted into the forming process analysis formula to obtain the forming process parameters for the complex space elbow to be bent;

[0048] The fifth step is to input the forming process para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com