Technological parameter determining method of metal material 3D printing

A 3D printing and metal material technology, applied in the field of 3D printing, can solve the problems affecting the final performance of parts, waste of manpower, material and financial resources, and lack of metal materials, etc., to shorten the parameter screening time, reasonable and reliable parameter values, and save time and cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] This embodiment takes the 3D printer (TSC-X350B), 200W laser, and metal material with the brand name GH3526 developed by Xinjinghe Laser Technology Development (Beijing) Co., Ltd. as examples, to specifically illustrate the process parameter determination method for 3D printing of metal materials in the present invention. , should not be interpreted as any restriction to the invention, its concrete method is as follows:

[0021] 1) Select qualified metal powder and prepare the same base material as the metal powder material category.

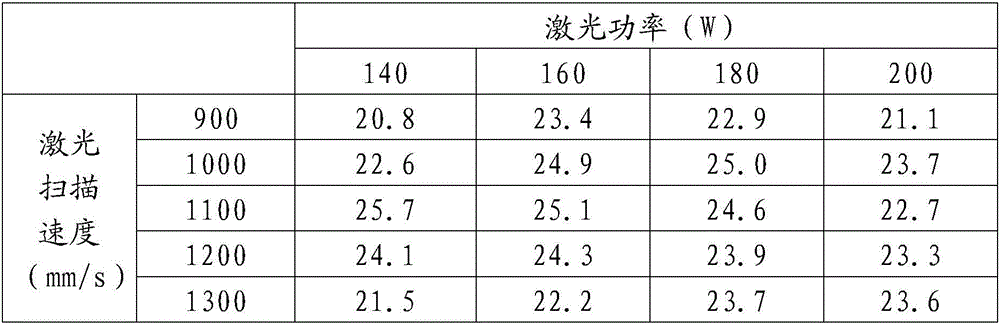

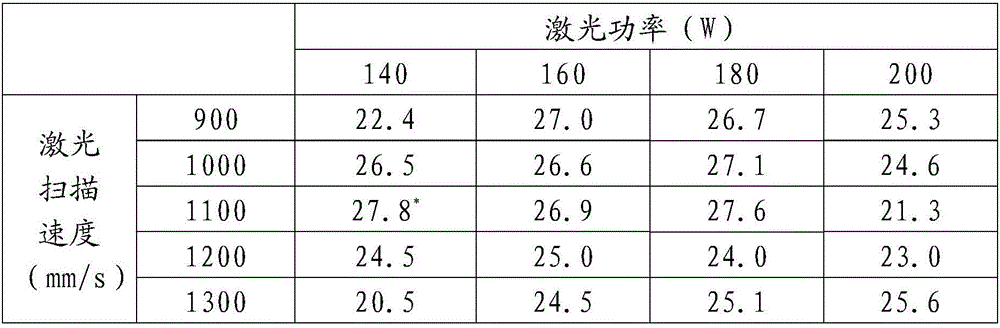

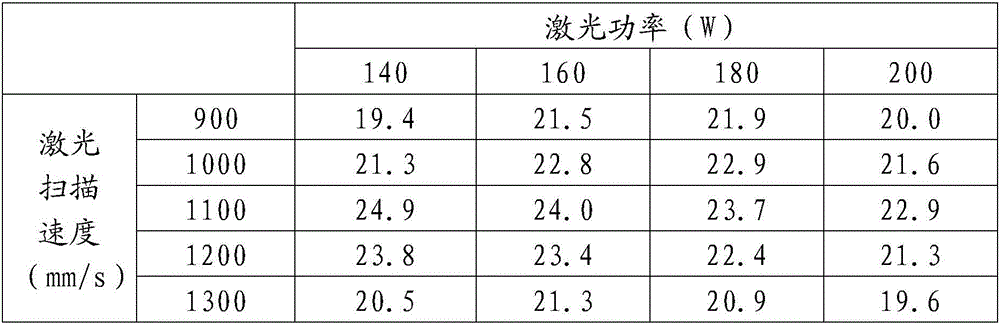

[0022] 2) According to the model of the 3D printer, determine the range of the laser power parameter as 60W to 200W, and determine 8 parameter values in a progressive manner with an equal difference of 20W; determine the range of the laser scanning speed parameter as 500mm / s to 1500mm / s, and determine 11 parameter values in a progressive manner with an equal difference of 100mm / s; determine the range of the powder layer thickness par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com