Austenitic stainless steel submerged arc welding wire

A technology of austenitic stainless steel and submerged arc welding wire, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve problems such as difficult control, achieve difficult selective deformation, stable chemical composition, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

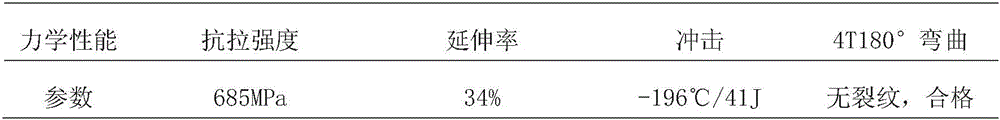

Examples

Embodiment 1

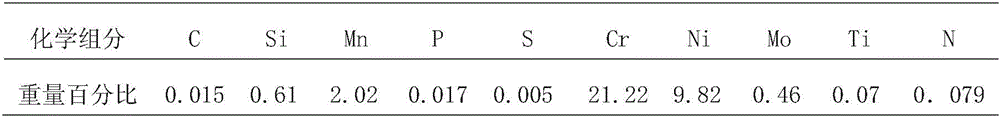

[0101] In order to achieve the purpose of the present invention, an austenitic stainless steel submerged arc welding wire includes submerged arc welding wire and deposited metal. The submerged arc welding wire in this embodiment is marked as submerged arc welding wire 1, and the chemical composition of submerged arc welding wire 1 is Concrete percentage by weight is as follows table 1:

[0102] The chemical composition weight percent (%) of table 1 submerged arc welding wire 1

[0103]

[0104] The sum of the weight percentages of the chemical components of the submerged arc welding wire 1 is 100%, and the rest is Fe.

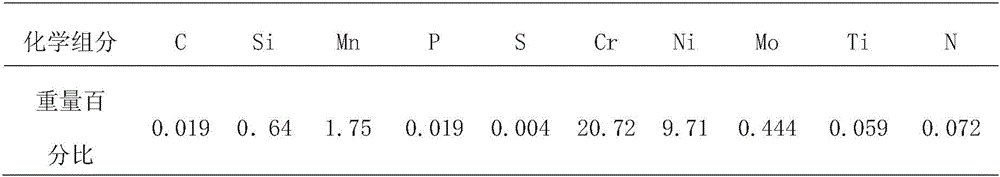

[0105] The deposited metal in this embodiment is marked as deposited metal 1, and the specific weight percentages of the chemical components of deposited metal 1 are as follows in Table 2:

[0106] The specific weight percentage (%) of the chemical composition of table 2 deposited metal 1

[0107]

[0108] The sum of the weight percentages of the chemic...

Embodiment 2

[0114] In order to achieve the purpose of the present invention, an austenitic stainless steel submerged arc welding wire includes submerged arc welding wire and deposited metal. The submerged arc welding wire in this embodiment is marked as submerged arc welding wire 2, and the chemical composition of submerged arc welding wire 2 is Concrete percentage by weight is as follows table 4:

[0115] The chemical composition weight percent (%) of table 4 submerged arc welding wire 2

[0116]

[0117] The sum of the weight percentages of the chemical components of the submerged arc welding wire 2 is 100%, and the remainder is Fe.

[0118] The deposited metal in this embodiment is marked as deposited metal 2, and the specific weight percentage of the chemical composition of deposited metal 2 is as follows in Table 5:

[0119] The specific weight percentage (%) of the chemical composition of table 5 deposited metal 2

[0120]

[0121] The sum of the weight percentages of the ch...

Embodiment 3

[0127] In order to achieve the purpose of the present invention, an austenitic stainless steel submerged arc welding wire includes submerged arc welding wire and deposited metal. The submerged arc welding wire in this embodiment is marked as submerged arc welding wire 3, and the chemical composition of submerged arc welding wire 3 Concrete weight percent is as follows table 7:

[0128] The chemical composition weight percent (%) of table 7 submerged arc welding wire 3

[0129]

[0130] The sum of the weight percentages of the chemical components of the submerged arc welding wire 3 is 100%, and the remainder is Fe.

[0131] The deposited metal in this embodiment is marked as deposited metal 3, and the specific weight percentage of the chemical composition of deposited metal 3 is as follows in Table 8:

[0132] The specific weight percentage (%) of the chemical composition of table 8 deposited metal 3

[0133]

[0134] The sum of the weight percentages of the chemical co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com