Module end plate production equipment and production method thereof

A technology for production equipment and end plates, applied in metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as low production efficiency, high labor intensity of workers, and poor processing accuracy, so as to reduce labor intensity and improve The effect of processing efficiency and processing accuracy, and reducing the number of repeated clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

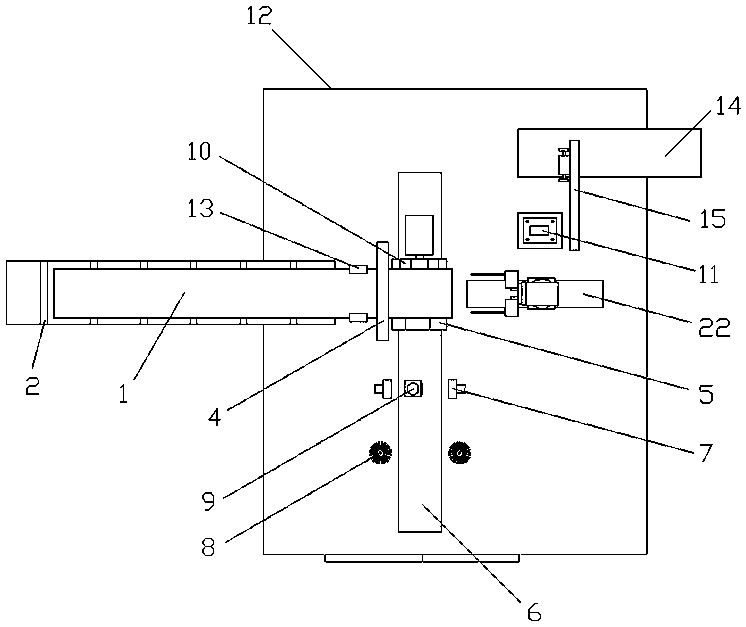

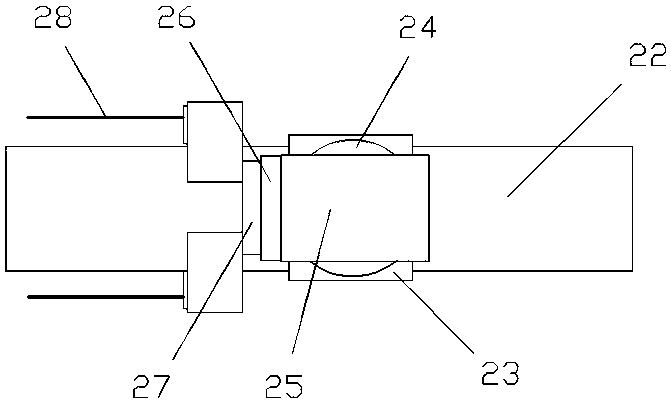

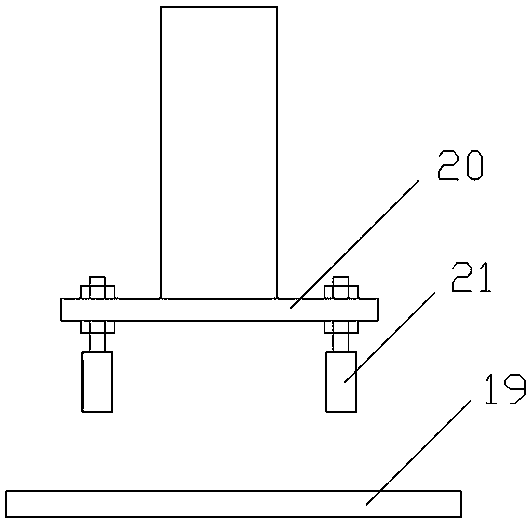

[0019] like Figure 1~5 As shown, a module end plate production equipment includes a feeding frame 2 for conveying aluminum sheet 1, and a sawing machine 4 is provided at the discharge end of the feeding frame 2 to cut the aluminum sheet into a predetermined length of module end plate 3 ; The right side of the sawing machine 4 is provided with a first sliding table 5 for conveying the module end plate 3 and can move back and forth, and the bottom of the first sliding table 5 is provided with a first sliding seat for sliding guidance of the first sliding table 5 6. On both sides of the first sliding seat 6, there are milling cutters 7 for milling the two ends of the module end plate when the first sliding table 5 passes by, and on both sides of the first sliding seat 6 on the front side of the milling cutter. The brush head 8 for removing the burrs on both ends of the module end plate 3 is located above the first sliding seat 6 and is also provided with a drill bit 9 for drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com