In-place detection method and device of airbag outline

A detection method and airbag technology, applied in the direction of surface polishing machine tools, parts of grinding machine tools, metal processing equipment, etc., can solve problems such as limited and not reaching the level of engineering application, to ensure consistency and improve removal effect , Improve the effect of stability and process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

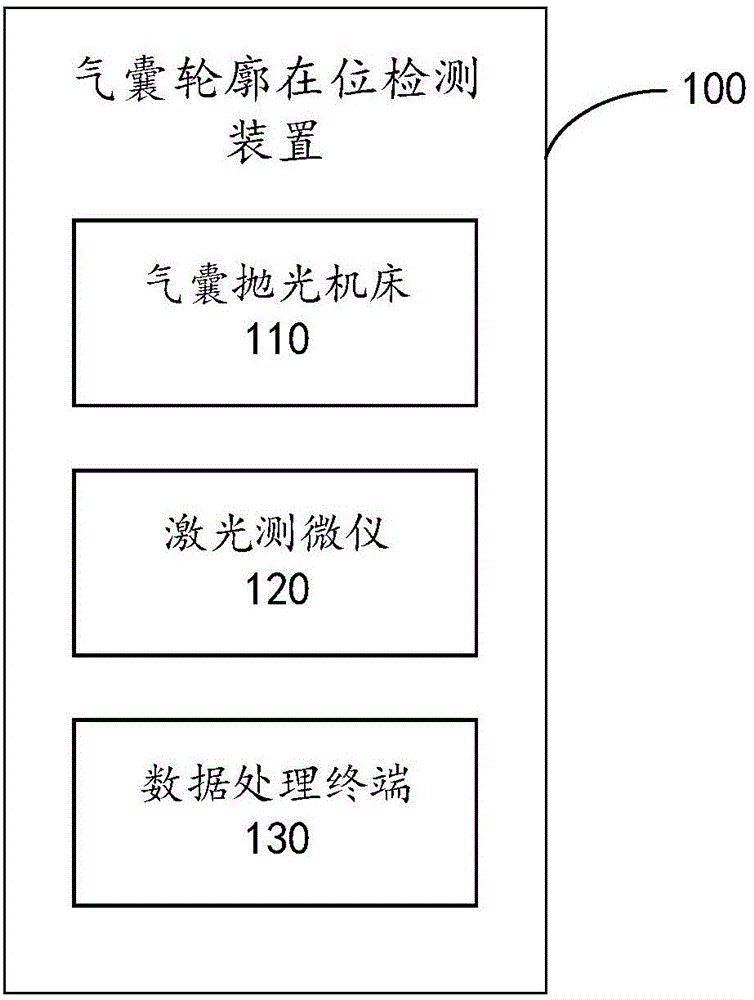

[0024] As an implementation manner, the airbag polishing machine tool 110 may be a 6-axis CNC machine tool, wherein the H axis is the rotation axis.

[0025] As an implementation manner, the laser micrometer 120 may be a Keyence laser micrometer 120 .

[0026] As an implementation manner, the data processing terminal 130 may be a computer.

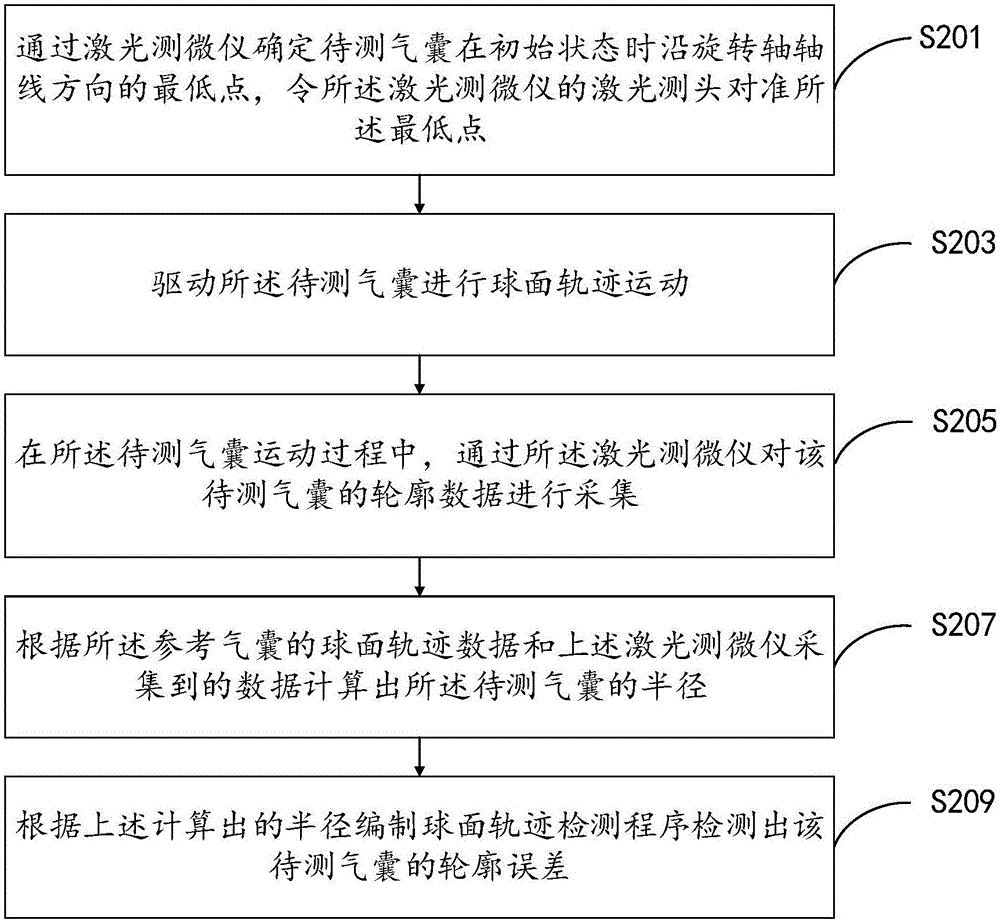

[0027] see figure 2 , is a method provided by the embodiment of the present invention that can be applied to figure 1 The flow chart of the detection method of the airbag contour in place of the device shown. It should be noted that the method in this example does not figure 2 and the specific order described below is a limitation. next to figure 2 Each step shown in is explained in detail.

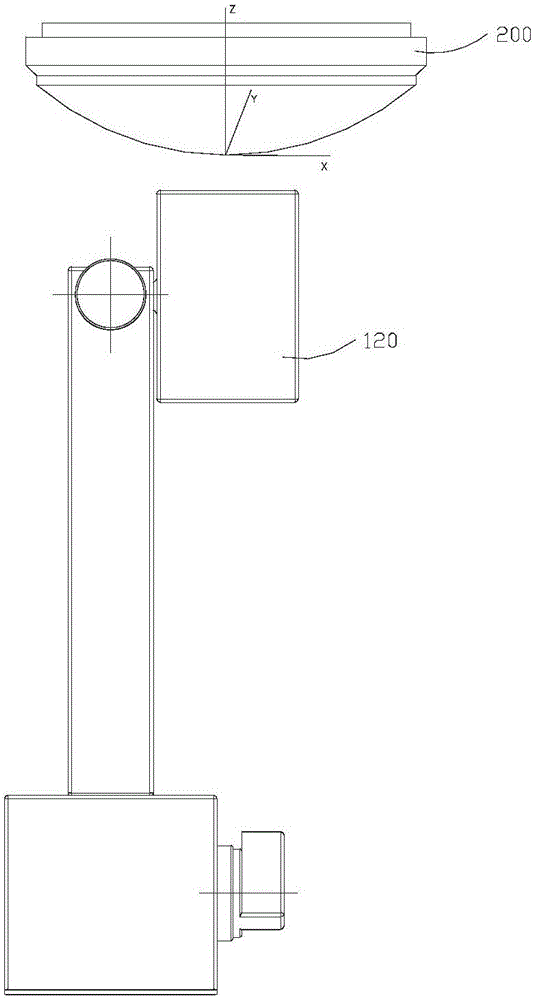

[0028] Step S201 , determine the lowest point of the airbag 200 to be tested along the axis of the rotation axis in the initial state by the laser micrometer 120 , and align the laser measuring head of the laser micrometer 120 to the lowest p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com