Preparation method for pressure equalizing plate used for forming of composite Z-pin reinforced stiffened plate

A composite material and pressure-equalizing plate technology, which is applied in the field of composite material manufacturing, can solve problems such as forming quality problems of reinforced wall panels, and achieve the effect of large market application value, simple manufacturing process and product quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

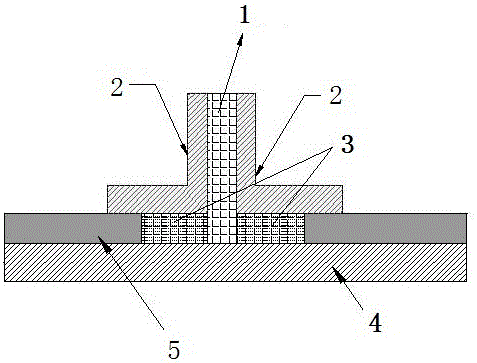

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] A kind of preparation method that is used for composite material Z-pin strengthened stiffened plate forming equalizing plate, the technology of this preparation method is as follows:

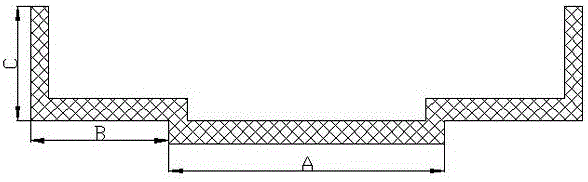

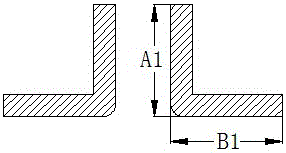

[0026] 1) According to the size and shape of the longitudinal ribs and skin of the Z-pin reinforced wall plate, order a set of metal master molds; then order another set of master molds according to the size of the transverse ribs; use the above two sets of master molds The mold was cleaned with acetone;

[0027] 2) Configure the glue solution according to the ratio requirements to prepare the prepreg;

[0028] 3) Pave and paste longitudinal ribs and skin conjoined equalizer plates and transverse rib equalizer plates on the corresponding molds, and calculate the number of paving layers according to the thickness of the reinforced wall plates;

[0029] 4) After curing at room temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com