A method and system for calculating the consumption of 3D printing model consumables

A technology of 3D printing and calculation method, applied in the field of 3D printing, can solve problems such as inaccurate quotations, achieve accurate product quotations, and solve the effect of inaccurate quotations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

[0024] The method for calculating the amount of consumables for 3D printing models proposed in this application is especially aimed at the calculation of consumables in the laser sintering (SLS) process using nylon materials in 3D printing.

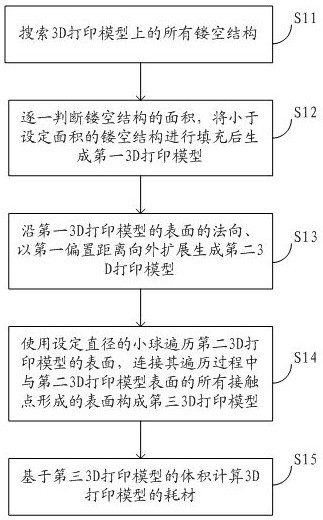

[0025] Such as figure 1 As shown, the calculation method for 3D printing model consumables proposed in this application includes the following steps:

[0026] Step S11: Search for all hollow structures on the 3D printing model.

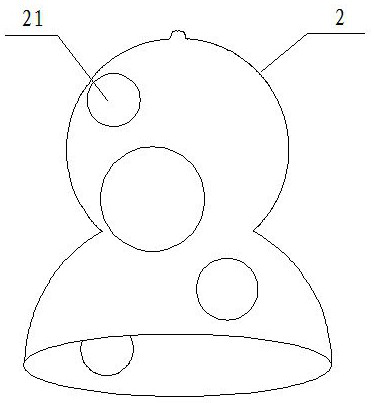

[0027] by figure 2 Taking the 3D printing model 2 shown as an example, all the hollow structures 21 are found by traversing its surface.

[0028] Step S12: Determine the area of the hollow structures one by one, and fill the hollow structures smaller than the set area to generate the first 3D printing model.

[0029] The searched hollow structures ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com