Friction hot melting device and method for PE pipes

A technology of friction heat and friction sheet, which is applied in the field of hot-melt welding of PE pipes, can solve the problems of large fluctuations in the temperature of the heating plate, affecting the control of the temperature of the heating plate, and the wide deviation range between the temperature of the heating plate and the requirements, so as to achieve saving Power consumption and the effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

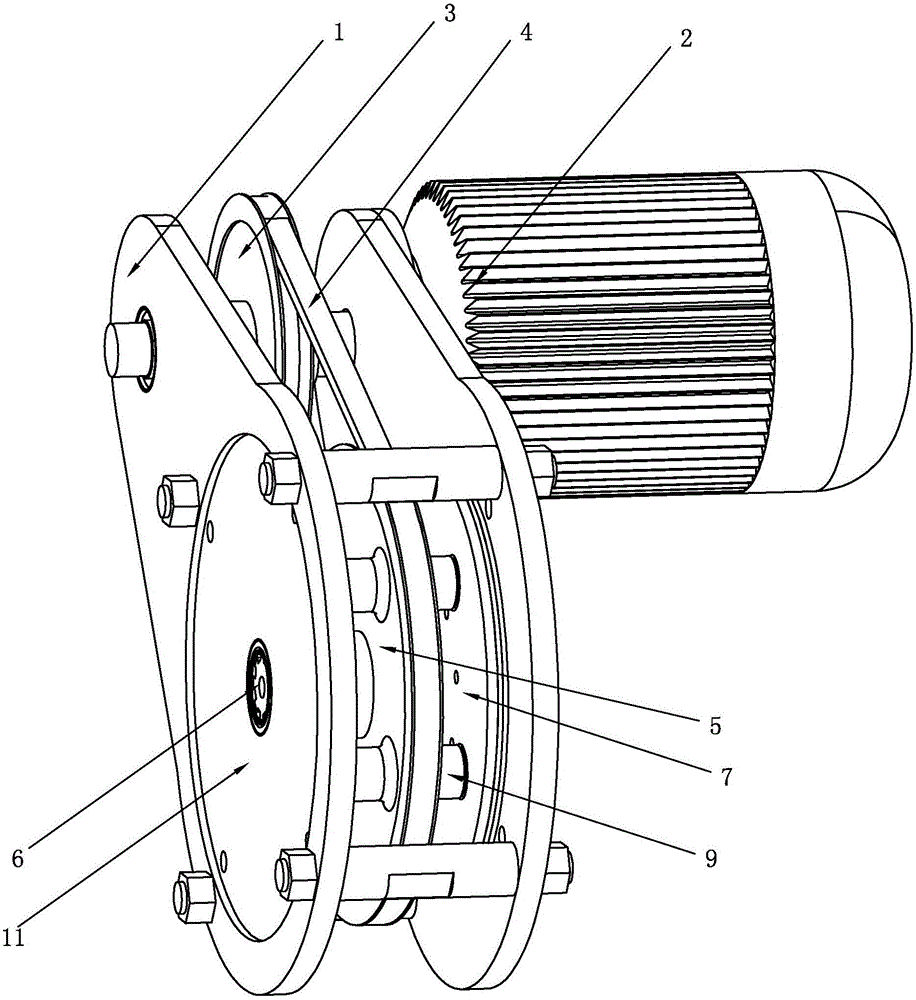

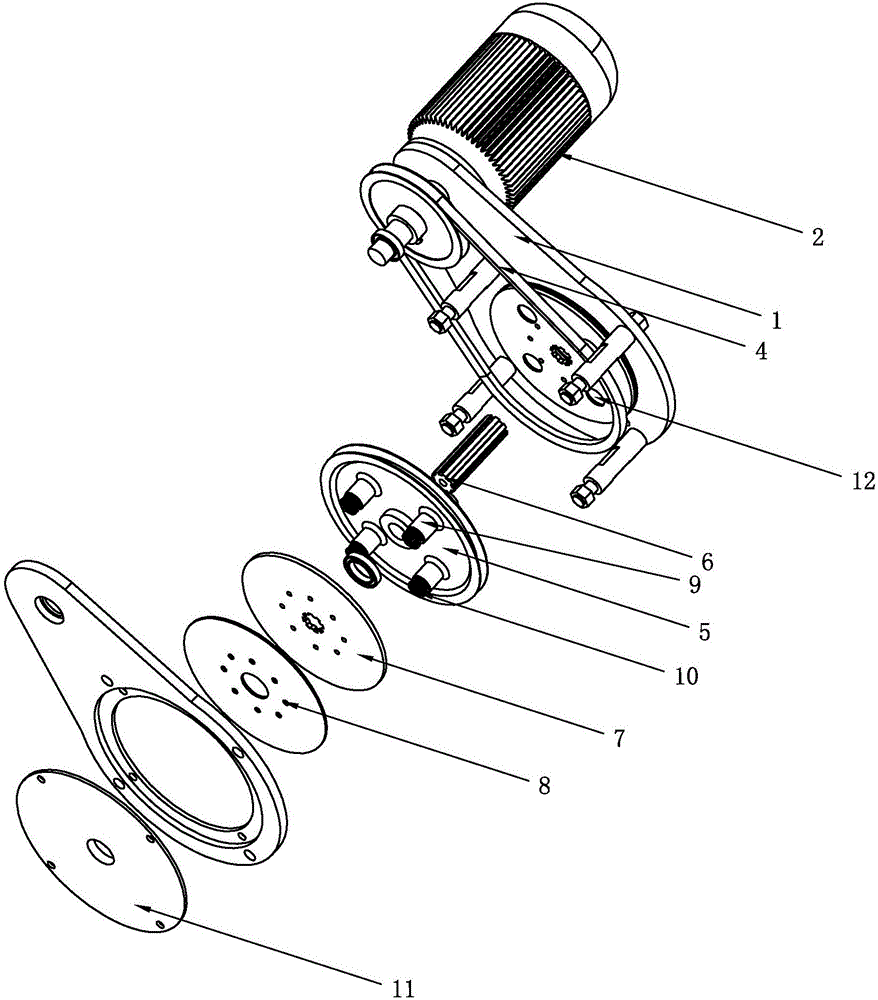

[0022] see figure 1 , a frictional hot-melt device for PE pipes of the present invention includes a bracket 1 and a drive motor 2 mounted on the bracket 1, the output shaft of the drive motor 2 is connected to a driving wheel 3, and the driving wheel 3 is connected by a belt 4 A driven wheel 5, a gear shaft 6 is installed at the center of the driven wheel 5, and a fixed disk 7 is engaged with both ends of the gear shaft 6.

[0023] see further figure 2 , the outer side of the fixed disk 7 is fixed with a friction plate 8, and the fixed disk 7 and the friction plate 8 are fixed by rivets. At least two sleeves 9 are provided on both sides of the driven wheel 5. In this embodiment, the Both sides of the driven wheel 5 are provided with four sleeves 9, and the four sleeves 9 are evenly distributed on the upper, lower, left, and right sides of the driven wheel 5. The sleeve 9 is sleeved with a stage clip 10, and the stage clip 10 One end abuts against the driven wheel 5, a posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com