Full-automatic fast and efficient rotating curved surface digital ink-jet printing machine

A digital inkjet and inkjet printing technology, applied in printing, typewriter and other directions, can solve the problems of slow printing speed and unstable printing quality, achieve high digital printing efficiency, short digital printing cycle, and meet the needs of rich colors and should be brushed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

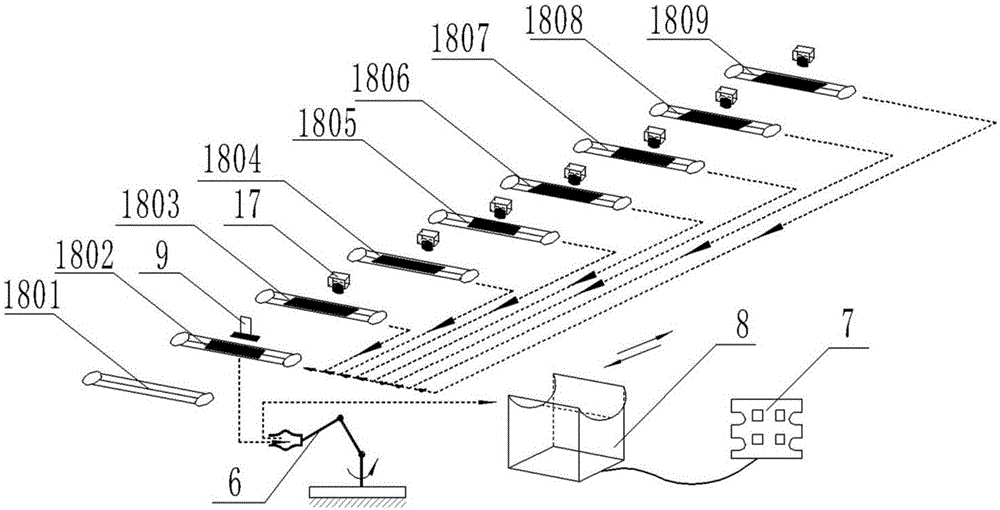

[0045] refer to Figure 4 , multi-color digital printing of elliptical bottles: the elliptical bottle product 18 is placed on the feeding conveyor belt, and the feeding conveyor belt transports the elliptical bottle product 18 to the bottle clamping position of the feeding industrial robot 6, and the industrial robot 6 clamps the elliptical bottle product 18. The bottle product 18 is rotated (90 degrees clockwise), and then sent to the product surface varnish and dust removal treatment position 1801, the surface treatment system is started, and the outer surface treatment of the oval bottle product 18 is carried out, and then the oval bottle product 18 is clamped by the industrial robot 6 Transposition to the first inkjet printing position 1803 on the surface of the product, the first group of nozzles of the multiple sets of digital nozzles 17 perform inkjet printing on the product, after the inkjet printing is completed, the multiple groups of digital nozzles 17 are operated b...

Embodiment example 2

[0047] refer to Figure 4 , multi-color digital printing of special-shaped bottles: the special-shaped bottle product 18 is placed on the feeding conveyor belt, and the feeding conveyor belt transports the special-shaped bottle product 18 to the bottle clamping position of the feeding industrial robot 6, and the industrial robot 6 clamps the special-shaped bottle product. The bottle product 18 is rotated (90 degrees clockwise), and then sent to the product surface varnish and dust removal treatment position 1801, the surface treatment system is activated, and the outer surface treatment of the special-shaped bottle product 18 is carried out, and then the special-shaped bottle product 18 is clamped by the industrial robot 6 Transposition to the first inkjet printing position 1803 on the surface of the product, the first group of nozzles of the multiple sets of digital nozzles 17 perform inkjet printing on the product, after the inkjet printing is completed, the multiple groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com