Mn<2+> activated white light glass and preparation method thereof

A glass and white light technology, applied in the field of luminescent materials, can solve the problems of complex mixing of different raw materials and proportional control processes, and reduced luminous efficiency, so as to avoid scattering and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

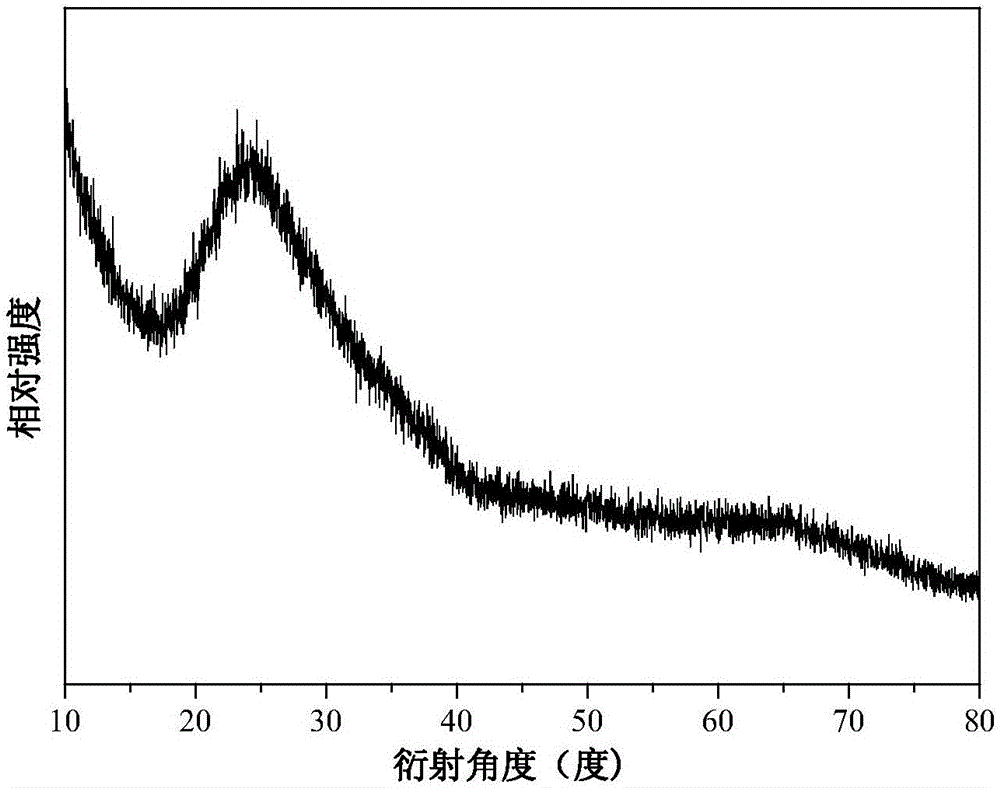

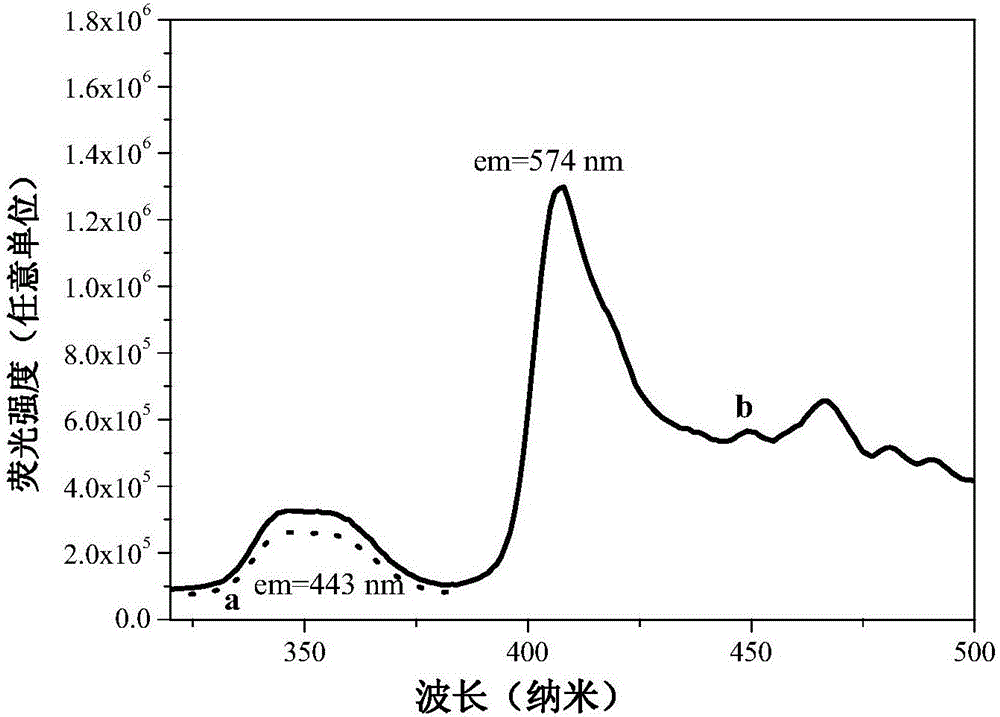

[0026] a kind of Mn 2+The preparation method of activated white light glass: the solid raw material 0.05mol (4.069g) ZnO, 0.02mol (1.236g) H 3 BO 3 , 0.08mol (9.202g) NH 4 h 2 PO 4 And 0.001mol (0.1149g) MnCO 3 Accurately weigh, grind, mix evenly according to the metering ratio, heat at 1250°C for 3 hours to a molten state, quickly transfer to a muffle furnace preheated to 550°C for annealing, and cool to room temperature to obtain white light glass products. Such as figure 1 As shown, the white light glass product is colorless and transparent under visible light, and emits bright white light under ultraviolet light. Product XRD (Bruker D8 Advance X-ray diffractometer detection) such as figure 2 As shown, there is only one amorphous peak in the figure, indicating that the product is in a glassy state. Utilize the Fluoromax-4 fluorescence spectrometer (HORIBA Jobin Yvon Inc.), detect the luminescent performance of the product under room temperature conditions, such as ...

Embodiment 2

[0028] a kind of Mn 2+ The preparation method of activated white light glass: the solid raw material 0.04mol (3.256g) ZnO, 0.04mol (2.473g) H 3 BO 3 , 0.08mol (9.202g) NH 4 h 2 PO 4 And 0.002mol (0.229g) MnCO 3 Accurately weigh, grind, mix evenly according to the metering ratio, heat at 1150°C for 2 hours to a molten state, quickly transfer to a muffle furnace preheated to 540°C for annealing, and cool to room temperature to obtain white light glass products. White light glass products are colorless and transparent under visible light, and emit bright white light under ultraviolet light. The appearance, XRD pattern and fluorescence spectrum of the white light glass are basically similar to those of Example 1.

Embodiment 3

[0030] a kind of Mn 2+ The preparation method of activated white light glass: the solid raw material 0.03mol (2.441g) ZnO, 0.06mol (3.701g) H 3 BO 3 , 0.08mol (9.202g) NH 4 h 2 PO 4 And 0.003mol (0.3447g) MnCO 3 Accurately weigh, grind, mix evenly according to the metering ratio, heat at 1100°C for 3 hours to a molten state, quickly transfer to a muffle furnace preheated to 580°C for annealing, and cool to room temperature to obtain white light glass products. White light glass products are colorless and transparent under visible light, and emit bright white light under ultraviolet light. The appearance, XRD pattern and fluorescence spectrum of the white light glass are basically similar to those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com