Low-temperature ceramic solidification method for high-arsenic heavy metal sludge

A technology of heavy metal sludge and low-temperature ceramics, which is applied in the fields of comprehensive utilization of resources and environmental protection, can solve the problems of not reducing the content of toxic substances in ceramics, and achieve the effects of prolonging the standing time, stabilizing the internal structure, and reducing the content of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

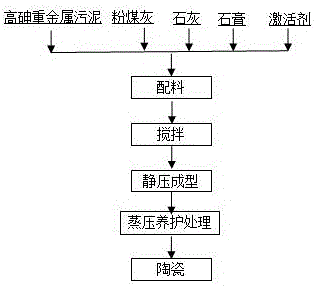

Method used

Image

Examples

Embodiment 1

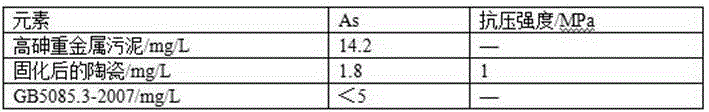

[0030] Example 1: The main components of high-arsenic heavy metal sludge in this example are shown in Table 1

[0031] Table 1 Main components of high-arsenic heavy metal sludge

[0032]

[0033] A low-temperature ceramic solidification method for high-arsenic heavy metal sludge, the specific steps are as follows:

[0034] (1) Ingredients: Weigh high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (activator is calcium hydroxide) in proportion, and the mass percentage of each component is 50% High-arsenic heavy metal sludge, 38% fly ash, 9% lime, 2.5% gypsum, 0.5% activator (calcium hydroxide); among them, the fly ash is Class I fly ash, and the CaO content in quicklime is 98%;

[0035] (2) Mixing: Mix the high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (calcium hydroxide) in step (1) evenly to obtain a mixed material;

[0036] (3) Static pressure molding: Under the condition of pressure of 5MPa, the mixed material in step (2) is sta...

Embodiment 2

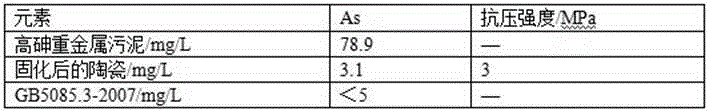

[0042] Example 2: The main components of high-arsenic heavy metal sludge in this example are shown in Table 3

[0043] Table 3 Main components of high-arsenic heavy metal sludge

[0044]

[0045] A low-temperature ceramic solidification method for high-arsenic heavy metal sludge, the specific steps are as follows:

[0046] (1) Ingredients: Weigh high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (activator is water glass) in proportion, and the mass percentage of each component is 10% High-arsenic heavy metal sludge, 50 % fly ash, 30% lime, 2.5% gypsum, 7.5% activator (water glass); among them, the fly ash is Class II fly ash, and the CaO content in quicklime is 99%;

[0047] (2) Mixing: Mix the high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (water glass) in step (1) evenly to obtain the mixed material;

[0048] (3) Static pressure forming: Under the condition of pressure of 15 MPa, the mixture in step (2) is statically formed and...

Embodiment 3

[0054] Example 3: The main components of high-arsenic heavy metal sludge in this example are shown in Table 5

[0055] Table 5 Main components of high-arsenic heavy metal sludge

[0056]

[0057] A low-temperature ceramic solidification method for high-arsenic heavy metal sludge, the specific steps are as follows:

[0058](1) Ingredients: Weigh high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (activator is calcium chloride) in proportion, and the mass percentage of each component is 32% High-arsenic heavy metal sludge, 47% fly ash, 18% lime, 2.5% gypsum, 0.5% activator (calcium chloride); among them, the fly ash is Class I fly ash, and the CaO content in quicklime is 96%;

[0059] (2) Mixing: Mix the high-arsenic heavy metal sludge, fly ash, lime, gypsum, and activator (calcium chloride) in step (1) evenly to obtain a mixed material;

[0060] (3) Static pressure forming: Under the condition of pressure of 30MPa, the mixed material in step (2) is stati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com