Method for preparing 1-adamantanol

A technology of adamantanol and chloroadamantane, which is applied in the field of preparation of 1-adamantanol, can solve the problems of unfavorable industrial production, long reaction time, complex process, etc., and achieve improved production efficiency, low environmental pollution, and post-processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

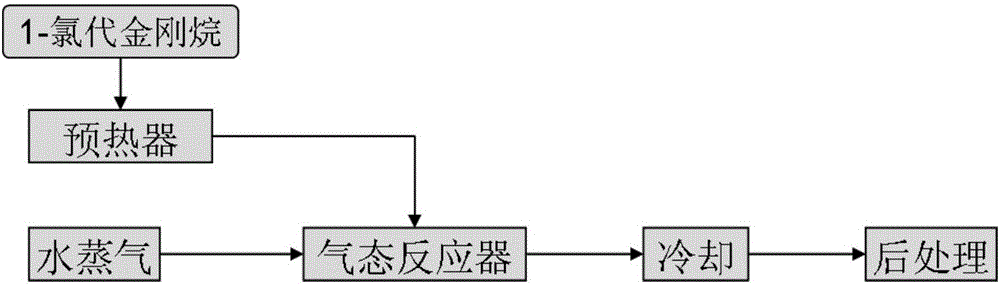

[0024] Such as figure 1 As shown, add 1.7g of 1-chloroadamantane into the preheater to vaporize, use an air pump to feed into the gaseous reactor, and feed water vapor at the same time, the reaction temperature is 160°C, and the reaction is 10s. Stop the reaction and cool to room temperature. The crude product of 1-adamantanol was obtained after filtration, and a sample was taken for GC analysis, and the conversion rate was 65.4%.

Embodiment 2

[0026] Such as figure 1 As shown, add 1.7g of 1-chloroadamantane into the preheater to vaporize, use an air pump to feed into the gaseous reactor, and feed water vapor at the same time, the reaction temperature is 160°C, and the reaction is 20s. Stop the reaction and cool to room temperature. The crude product of 1-adamantanol was obtained after filtration, and a sample was taken for GC analysis, and the conversion rate was 80.3%.

Embodiment 3

[0028] Such as figure 1 As shown, add 1.7g of 1-chloroadamantane into the preheater to vaporize, use an air pump to feed into the gaseous reactor, and feed water vapor at the same time, the reaction temperature is 170°C, and the reaction is 10s. Stop the reaction and cool to room temperature. The crude product of 1-adamantanol was obtained after filtration, and a sample was taken for GC analysis, and the conversion rate was 90.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com