Production method of injection molding material with high melting point and thin wall

A production method and plastic injection technology, which is applied in the field of polypropylene production, can solve the problems of high production cost and achieve the effects of reduced production cost, good transparency and good product fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

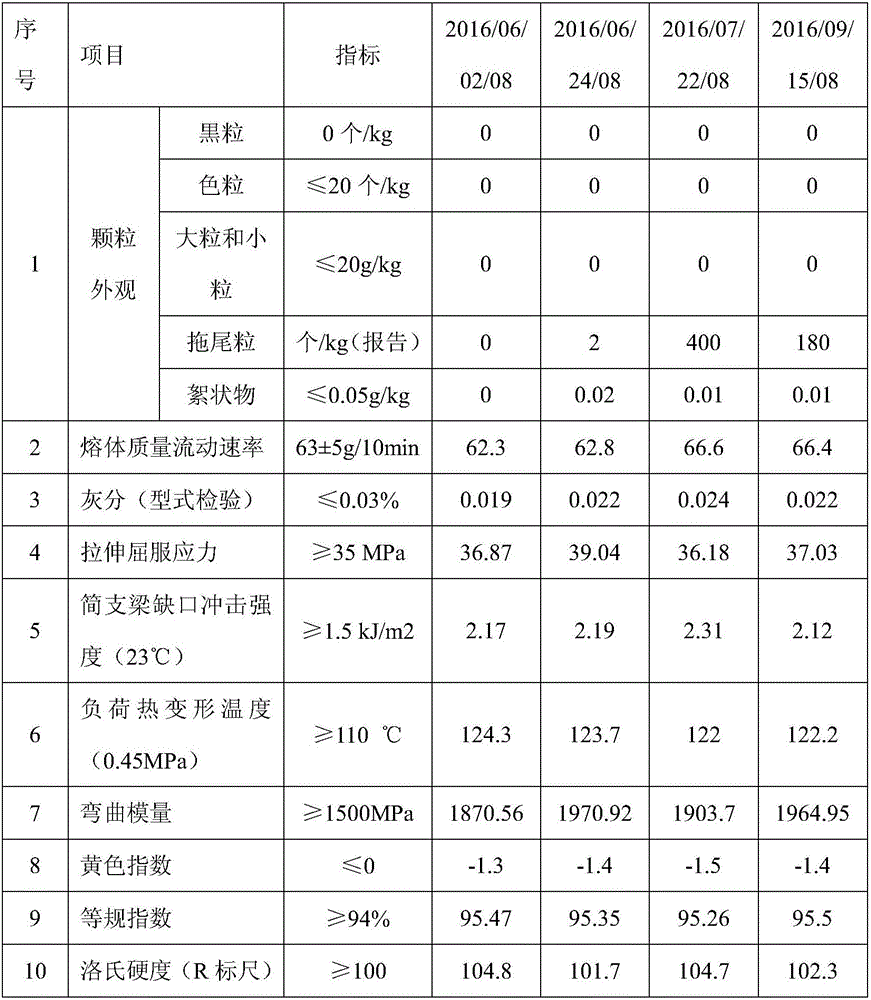

Examples

Embodiment 1

[0033] The production method of the high-melt thin-walled injection molding compound comprises the following steps: (1) purification and supply of propylene raw materials; (2) propylene polymerization; (3) resin degassing; (4) tail gas recovery; (5) granulation; (6) air delivery and packing; described step (2) propylene polymerization reaction and step (5) granulation specific process conditions and parameters are as follows:

[0034] a. Reduce catalyst feed rate to 0.6kg / h;

[0035] b. Reduce the partial pressure of propylene in the reactor to 2.5MPa, and reduce the temperature of the reactor to 65°C;

[0036] c. After 30 minutes, add hydrogen into the reactor at an intake rate of 2kg / h. After the reaction is normal, continue to increase the amount of hydrogen added; in the process of increasing the partial pressure of hydrogen, increase the feed of fresh propylene or reduce the bed temperature to ensure that the bed Layer temperature and dew point temperature difference in ...

Embodiment 2

[0054] The production method of the high-melt thin-walled injection molding compound comprises the following steps: (1) purification and supply of propylene raw materials; (2) propylene polymerization; (3) resin degassing; (4) tail gas recovery; (5) granulation; (6) air delivery and packing; described step (2) propylene polymerization reaction and step (5) granulation specific process conditions and parameters are as follows:

[0055] a. Reduce catalyst feed rate to 0.6kg / h;

[0056] b. Reduce the partial pressure of propylene in the reactor to 2.7MPa, and reduce the temperature of the reactor to 70°C;

[0057]c. After 30 minutes, add hydrogen into the reactor at an intake rate of 2kg / h. After the reaction is normal, continue to increase the amount of hydrogen added; in the process of increasing the partial pressure of hydrogen, increase the feed of fresh propylene or reduce the bed temperature to ensure that the bed Layer temperature and dew point temperature difference in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com