A kind of efficient synthetic method of polyphenylene sulfide resin

A technology of polyphenylene sulfide resin and synthesis method, which is applied in the field of organic polymer resin production, can solve the problems of uneven particle size of the final product, unstable resin melt index, low yield of polyphenylene sulfide resin, etc., and achieve product Good particle uniformity, avoiding scarring, and maintaining the effect of particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

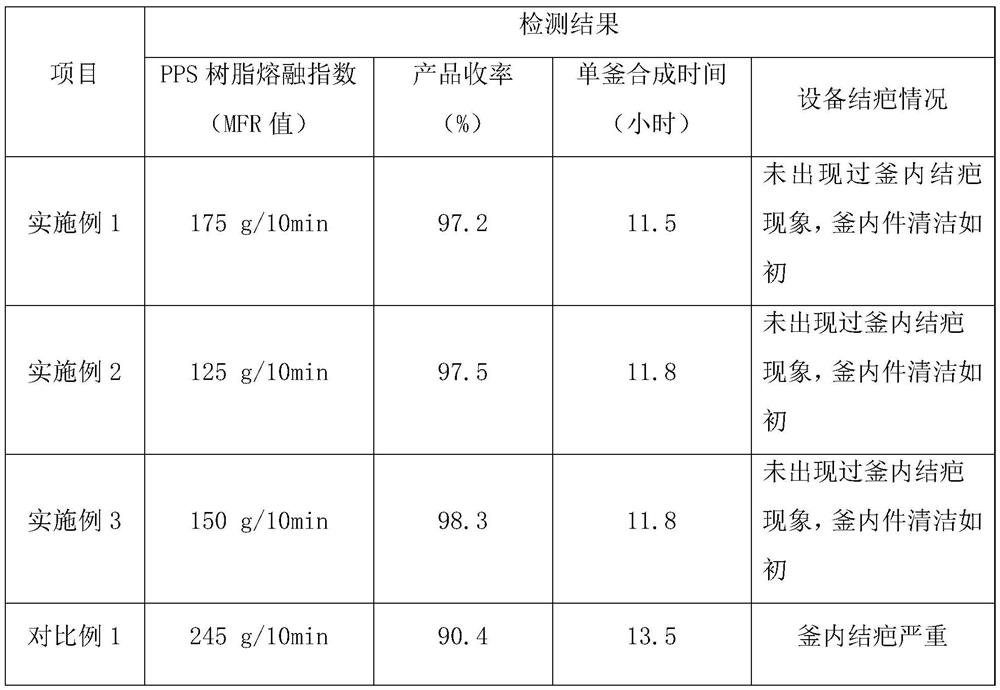

Examples

Embodiment 1

[0033] A kind of efficient synthetic method of polyphenylene sulfide resin, it comprises steps:

[0034] (1) Dissolve the sulfur source in NMP, and carry out dehydration treatment under the protection of an inert gas in the presence of a catalyst and an alkali to complete the intermediate and the remaining mixed solution separated by dehydration, and then add p-DCB to the intermediate Carry out polymerization reaction with NMP, obtain polyphenylene sulfide resin mixture slurry;

[0035] (2) After the above-mentioned polymerization reaction, the temperature of the material in the reaction vessel is 250°C, the pressure in the kettle is 0.9Mpa, and the stirring speed is 100rpm, and then the coil of the reaction vessel is opened to cool the heat transfer oil to cool down the above-mentioned polyphenylene sulfide resin mixture slurry, When the temperature in the kettle drops to 245°C, use a pump to add the remaining mixed liquid at room temperature under the condition of a stirring...

Embodiment 2

[0038] A kind of efficient synthetic method of polyphenylene sulfide resin, it comprises steps:

[0039] (1) Dissolve the sulfur source in NMP, and carry out dehydration treatment under the protection of an inert gas in the presence of a catalyst and an alkali to complete the intermediate and the remaining mixed solution separated by dehydration, and then add p-DCB to the intermediate Carry out polymerization reaction with NMP, obtain polyphenylene sulfide resin mixture slurry;

[0040](2) After the above-mentioned polymerization reaction, the temperature of the material in the reaction vessel is 265°C, the pressure in the kettle is 1.1Mpa, and the stirring speed is 80rpm, and then the coil cooling water of the reaction vessel is opened to cool down the above-mentioned polyphenylene sulfide resin mixture slurry. When the temperature in the kettle drops to 260°C, use a pump to add the remaining mixed solution at room temperature under the condition of a stirring speed of 80rpm,...

Embodiment 3

[0043] A kind of efficient synthetic method of polyphenylene sulfide resin, it comprises steps:

[0044] (1) Dissolve the sulfur source in NMP, and carry out dehydration treatment under the protection of an inert gas in the presence of a catalyst and an alkali to complete the intermediate and the remaining mixed solution separated by dehydration, and then add p-DCB to the intermediate Carry out polymerization reaction with NMP, obtain polyphenylene sulfide resin mixture slurry;

[0045] (2) After the above-mentioned polymerization reaction, the temperature of the material in the reaction vessel is 260°C, the pressure in the kettle is 1.0Mpa, and the stirring speed is 80rpm, and then the coil cooling water of the reaction vessel is opened to cool down the above-mentioned polyphenylene sulfide resin mixture slurry. When the temperature in the kettle drops to 250°C, then use a pump to add the remaining mixed liquid at room temperature under the condition of a stirring speed of 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com