Polyolefin composite and preparation method thereof

A composition, polyolefin foaming technology, applied in the direction of coating, etc., can solve the problems involving less foam core layer composition and preparation method, poor fluidity, etc., and achieve the effect of increased melt viscosity and uniform and dense bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

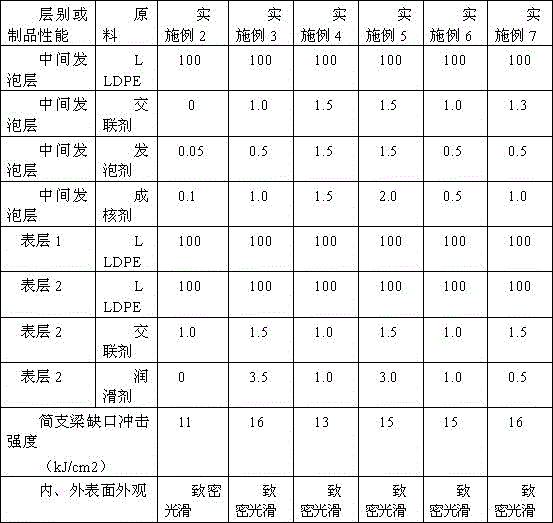

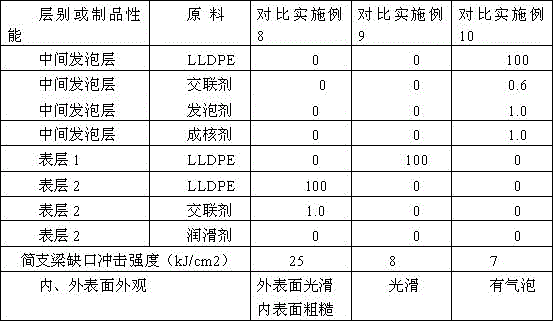

Examples

Embodiment 1

[0045] Embodiment 1 polyolefin foaming composition, and is used for making rotomolding foamed article

[0046] a. Preparation of middle foam layer resin:

[0047] Ⅰ. Mixing: Put 100 parts by weight of linear low-density polyethylene (LLDPE) into a high-speed mixer that has been heated to 60°C in advance, start the high-speed mixer, and when the temperature of LLDPE rises to 60°C, add pre-mixed uniform cross-linked 0.5 parts by weight of foaming agent, 0.1 parts by weight of blowing agent, and 0.2 parts by weight of nucleating agent are mixed at 60°C for 5 minutes and then discharged, sealed and stored for granulation;

[0048] II Granulation: control the temperature at 10±2°C above the melting point of LLDPE, extrude and granulate, and store in a sealed container; it is used for grinding and screening;

[0049] Ⅲ Grinding and sieving: After grinding, sieve the powder with a particle size of 20-30 meshes for rotational molding;

[0050] b. Surface layer 1 resin preparation: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com