Two-color injection molding composite material for wall switch panel

A two-color injection molding and composite material technology, which is applied in the field of composite materials, can solve the problems of non-flame retardant, heat resistance, fracture, and poor material, and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

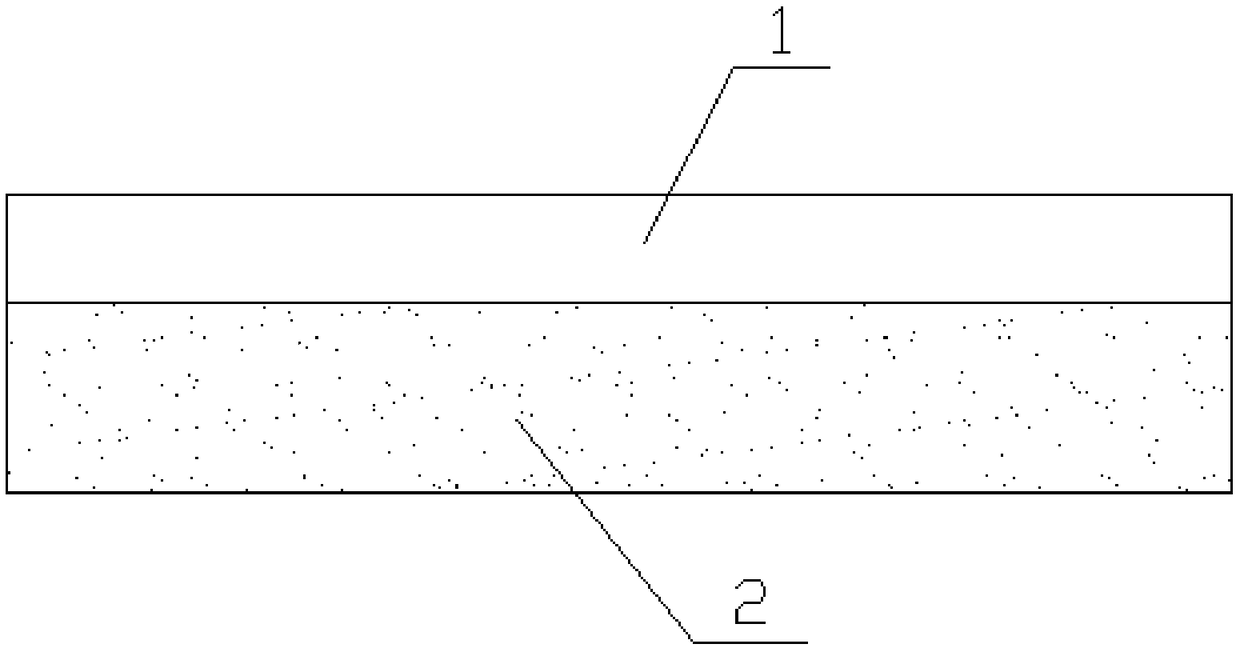

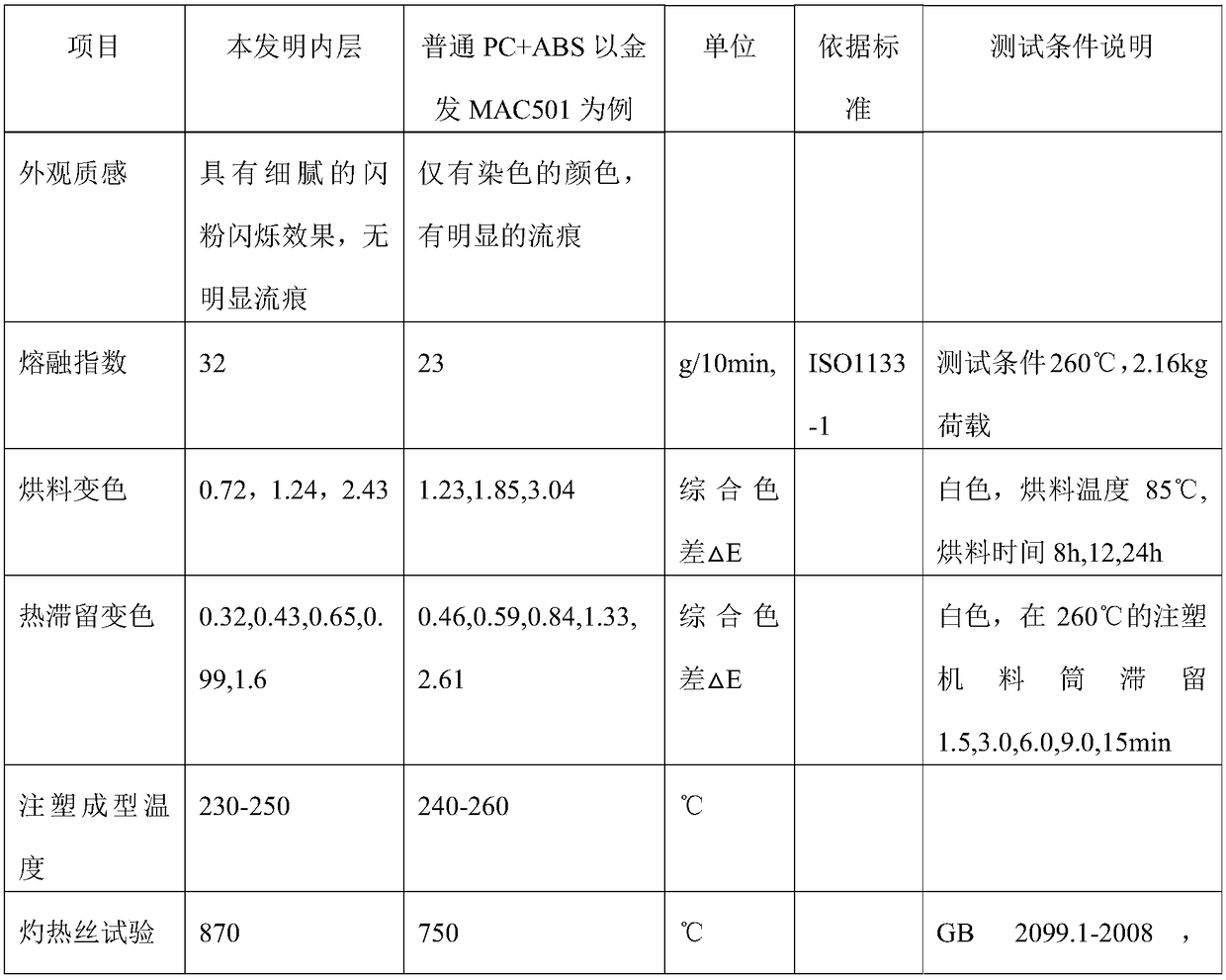

[0028] A two-color injection molding composite material for a wall switch panel, the two-color injection molding composite material is a two-layer composite structure, including a transparent PC outer layer 1 and an opaque PC / ABS inner layer 2 ( figure 1 ), the weight ratio of each raw material component of the PC / ABS inner layer is: 55-65 parts of PC, 15-25 parts of ABS, 4-7 parts of flame retardant, 3-7 parts of flow modifier, flash 1-3 parts of powder, 3-5 parts of compatibilizer, 3-5 parts of toughening modifier, 0.5-2 parts of toner dispersant, 0.1-0.5 parts of toner, 0.4-0.7 parts of injection molding improvement additive, 0.1-0.3 parts of UV additives, 0.1-0.3 parts of antioxidants.

[0029] Specific implementation:

Embodiment 1

[0031] Such as figure 1 As shown, the two-color injection molding composite material includes a transparent PC outer layer 1 and an opaque PC / ABS inner layer 2 . The distribution ratio of the two components of the inner layer is: PC 60kg, ABS 19kg, flame retardant 5kg, flow modifier 5kg, flash powder 2kg, compatibilizer 4.7kg, toughening modifier 3kg, toner dispersant 0.5kg , 0.1kg of toner, 0.5kg of injection molding improvement additives, 0.1kg of anti-UV additives, and 0.1kg of antioxidants.

[0032] The proportions of the various components in this embodiment are the preferred proportions in the interval. The preferred reason is that when the conversion of PC accounts for 60%, the fluidity, heat resistance, strength and flame retardancy of the material reach the best balance, and the PC content When the ratio is higher than this, it is necessary to add more fluidity improving additives and reduce the content of ABS. Excessive addition of fluidity improving additives will ...

Embodiment 2

[0051] Such as figure 1 As shown, the two-color injection molding composite material includes a transparent PC outer layer 1 and an opaque PC / ABS inner layer 2 . The composition ratio of the opaque inner layer is: PC 60kg, ABS 19kg, flame retardant 5kg, flow modifier 5kg, flash powder 2kg; compatibilizer 4.7kg, toughening modifier 3kg, toner dispersant 0.5kg , Toner 0.1kg, injection molding improvement additive 0.5kg, anti-UV additive 0.1kg, antioxidant 0.1kg.

[0052] The proportions of the various components in this embodiment are interval preferred proportions, the proportions are exactly the same as in Example 1, and the reasons for the preference are also exactly the same, and will not be repeated.

[0053] The detailed composition or the brand description of various components in this embodiment are as follows:

[0054] PC is high heat resistance and high fluidity PC grade S-3000VR

[0055] ABS is a high heat-resistant grade; ABS 747

[0056] The flash powder is: met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com