Hot bending film for radian screen as well as preparation method and application thereof

A film layer and base film technology, which is applied to the field of thermal bending film for curved screen and its preparation, can solve the problems that the flat film cannot be perfectly fitted to the mobile phone, the screen of the mobile phone is easily broken or scratched, and the function of the mobile phone is reduced, and the like. Good abrasion resistance, good anti-scratch effect, good transparency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

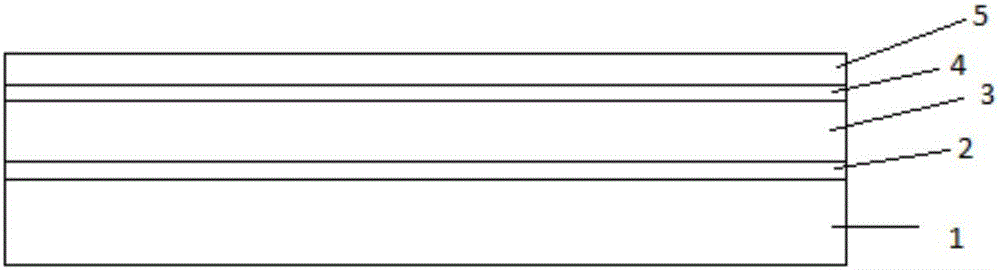

[0085] In this embodiment, the structure of the hot bending film is as figure 1 As shown, it includes a pressure-sensitive adhesive layer (1), a first polyurethane adhesive layer (2), a PET resin film layer (3), a second polyurethane adhesive layer (4) and a cured PUA film layer (5) from bottom to top, The shrinkage rate of the PET resin film layer is 0.8%.

[0086] Wherein the thickness of the pressure-sensitive adhesive layer is 42 μm, the thickness of the first polyurethane adhesive layer is 280 nm, the thickness of the PET resin film is 100 μm, the thickness of the second polyurethane adhesive layer is 280 nm, and the thickness of the cured PUA film layer is 2 μm. The shrinkage rate of the lower base film layer and the upper base film layer is 0.5%.

[0087] The cured PUA film layer is a cured PUA film layer obtained by ultraviolet curing of polyurethane acrylate, and the number average molecular weight of the polyurethane acrylate is 20000;

[0088] The concrete prepara...

Embodiment 2

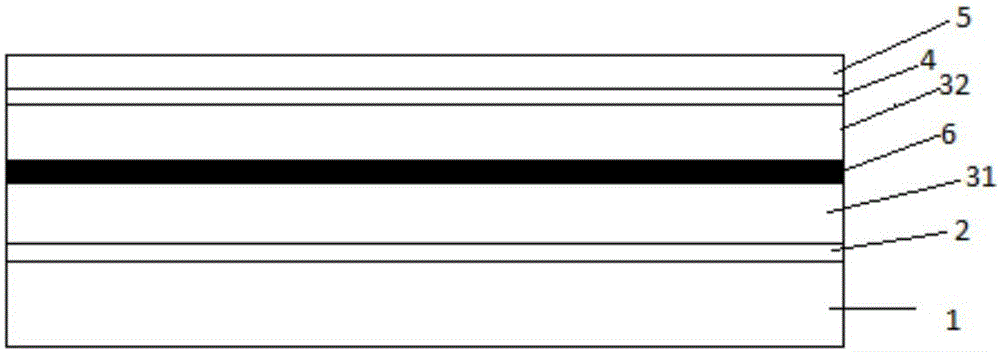

[0096] In this embodiment, the structure of the hot bending film is as figure 2 As shown, from bottom to top, it includes pressure-sensitive adhesive layer (1), first polyurethane adhesive layer (2), first PET resin film (31), composite OCA adhesive layer (6), second PET resin film (32) , the second polyurethane adhesive layer (4) and the cured PUA film layer (5), the shrinkage rate of the PET resin film layer is 0.6%.

[0097]The thickness of the pressure-sensitive adhesive layer is 10 μm, the thickness of the first polyurethane adhesive layer is 100 nm, the thickness of the first PET resin film is 25 μm, the thickness of the composite OCA adhesive layer is 10 μm, the thickness of the second PET resin film is 20 μm, and the thickness of the second PET resin film is 20 μm. The thickness of the two polyurethane adhesive layers is 150 nm, and the thickness of the cured PUA film layer is 3.5 μm. The shrinkage rate of the lower base film layer and the upper base film layer is 0....

Embodiment 3

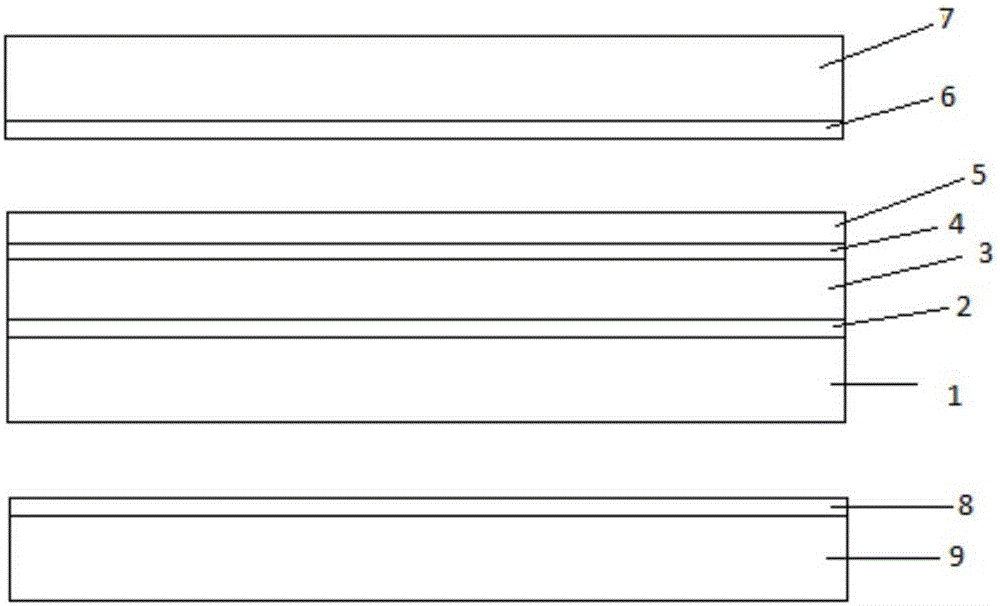

[0107] In this embodiment, the structure of the hot bending film is as image 3 As shown, it includes the lower base film layer (9), the release film layer (8), the pressure-sensitive adhesive layer (1), the first polyurethane adhesive layer (2), the PET resin film layer (3), the second Two polyurethane adhesive layers (4), cured PUA film layer (5), protective adhesive layer (6) and lower base film layer (7), the shrinkage rate of the PET resin film layer is 0.5%.

[0108] The thickness of the lower base film layer is 75 μm, the thickness of the release film layer is 300 μm, the thickness of the pressure-sensitive adhesive layer is 20 μm, the thickness of the first polyurethane adhesive layer is 220 nm, the thickness of the PET resin film layer is 50 μm, the second polyurethane adhesive The thickness of the layer is 220 nm, the thickness of the cured PUA film layer is 3 μm, the thickness of the protective adhesive layer is 50 μm and the thickness of the upper base film layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com