Disposable intelligent digester system for animal cell culture

A kind of animal cell culture, disposable technology, applied in the field of disposable intelligent digester system, can solve the problems of increasing production cost, difficult to repeat the results, organic pollution and other problems, achieve the effect of simplifying steps, reducing complexity and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

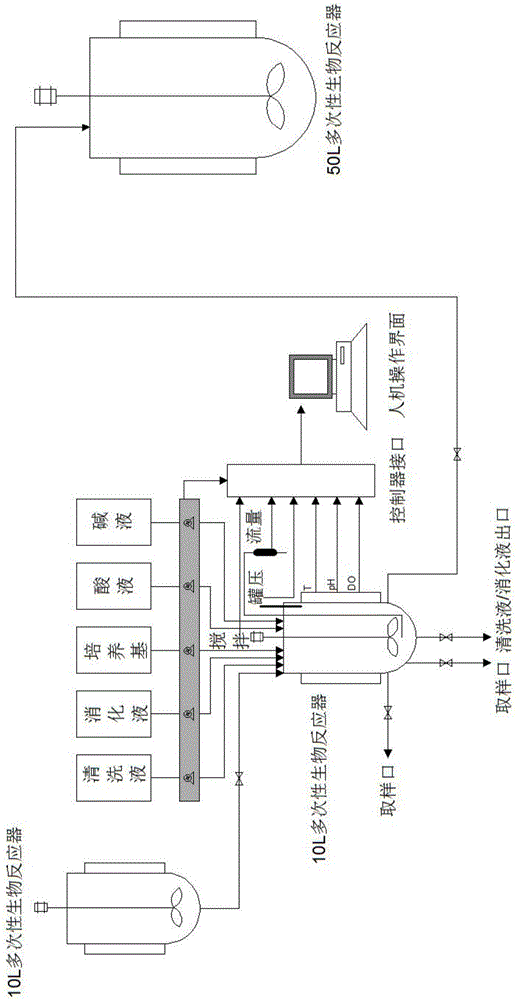

Method used

Image

Examples

Embodiment 1

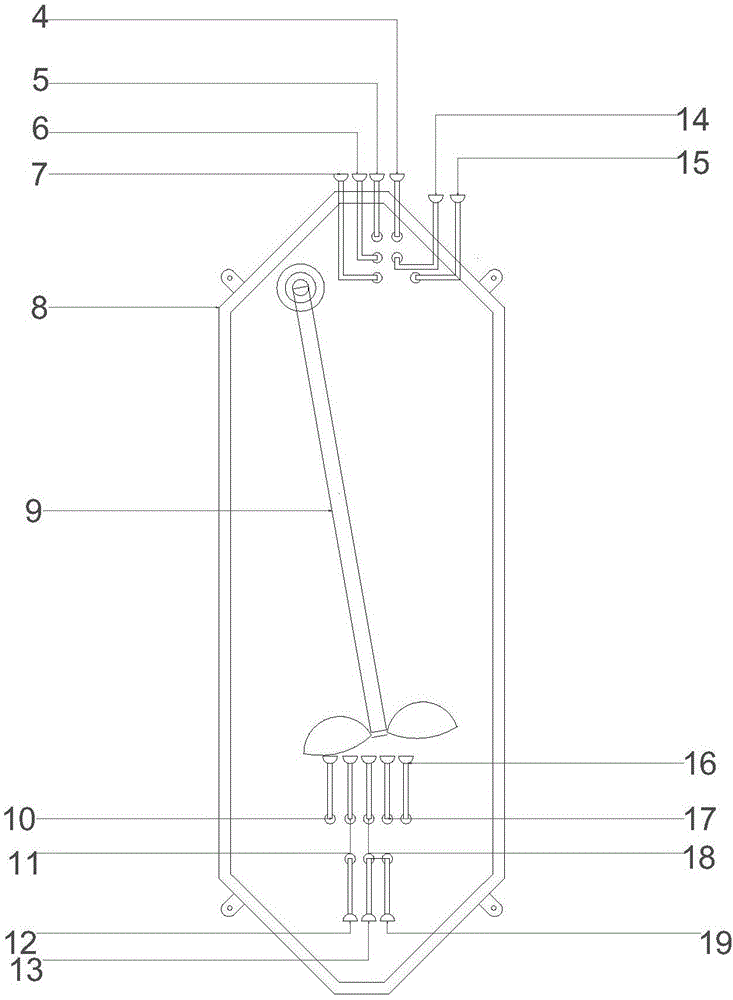

[0107] see Figure 5 As shown, the 10L disposable bioreactor in this embodiment is used as a seed reactor to carry out microcarrier cell suspension culture; the 10L disposable digester is used as a place for the digestion reaction of the seed cells that have been cultivated to realize the separation of PK-15 cells and microcarriers. The isolated cells were transferred to a 50L disposable bioreactor for further culture. The working volumes of 10L and 50L multiple bioreactors are 7L and 35L respectively. The height-to-diameter ratio of the reactor is 1.8:1.0. 10L disposable digester unit structure design such as figure 2 , 3 , 4, the working volume is 7L. The 10L disposable digester carrier medium used Cytodex-1 produced by GE Company, 3g / L, and the cell density was 2.5×106cells / mL. The digestive reaction is carried out as figure 2 As shown, the specific implementation steps are as follows:

[0108] (i) Liquid preparation stage: Prepare 20L of cleaning solution, 1L of di...

Embodiment 2

[0115] see Figure 6 As shown, the 90L disposable bioreactor in this embodiment is used as a seed reactor to carry out microcarrier cell suspension culture; the 90L disposable digester is used as a place for the digestion reaction of the seed cells that have been cultivated to realize the separation of PK-15 cells and microcarriers. The isolated cells are transferred to a 300L disposable bioreactor for further culture. The working volumes of 90L and 300L disposable bioreactors are 63L and 210L respectively. The height-diameter ratio of the reactor is 1.8:1.0. The disposable digester and the 10L disposable digester have geometric similarity characteristics, and other digestion steps refer to Example 2, and the specific implementation flow chart is as follows Figure 6 shown, and will not be repeated here.

[0116] The medium rich in free-suspending cells is pumped to a 300L disposable bioreactor, while the carrier is retained in a 90L disposable digester by the retention asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com