Preparation method for NiCrAl foam metal

A foam metal and foam technology is applied in the field of electrothermal alloy preparation, which can solve the problems of difficult alloy performance, low density, high apparent resistivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate and understand the present invention through embodiment below.

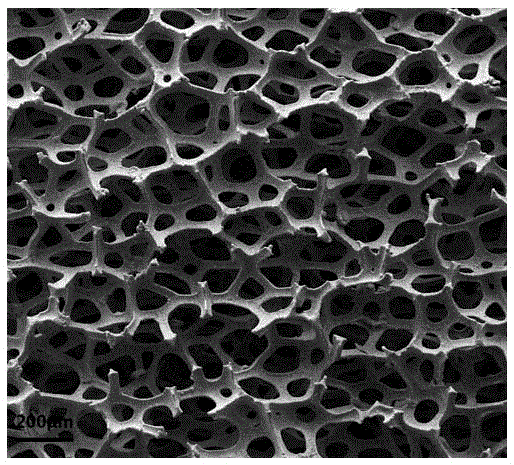

[0016] The preparation method of NiCrAl foam metal adopts sintering process to prepare foam NiCr alloy, on the basis of foam NiCr alloy, adopts powder embedding method to infiltrate Al, infiltrating agent is made of aluminum-nickel alloy powder, Al 2 O 3 Powder and NH 4 Cl composition, forming NiCrAl foam metal.

[0017] The sintering process includes:

[0018] ⑴Batching: according to the ratio of Cr: 26.6%, Fe: 2.7%, Mn: 0.7%, Nb: 0.8%, Mo: 1.4%, Zr: 4%, and the balance is nickel;

[0019] (2) Ball milling: After grinding in a high-energy ball mill for 14 hours, an alloy powder with an average particle size of 35 um is obtained;

[0020] (3) Sintering: put the mold filled with the above alloy powder into a sintering device, and sinter under vacuum conditions while pressurizing, the sintering temperature is 1260°C, and the time is 2.5 hours to obtain a foamed NiCr alloy.

[0021] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com