A kind of high-strength tensile type cold-rolled strip steel and its preparation method

A technology of cold-rolled strip steel and tensile type, which is applied in the field of stainless steel manufacturing, can solve problems such as waste, affecting production speed, and low passivation rate, and achieves enhanced structural strength and hardness performance, good fluidity and transmission performance, and reduced cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

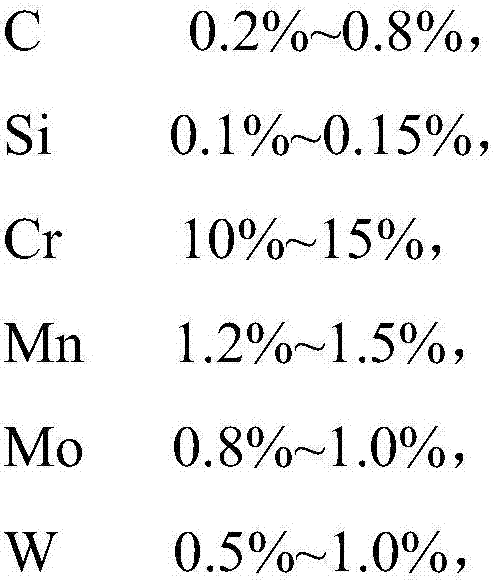

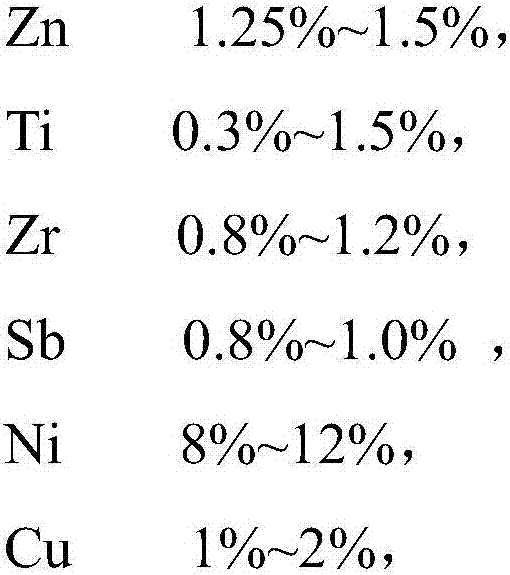

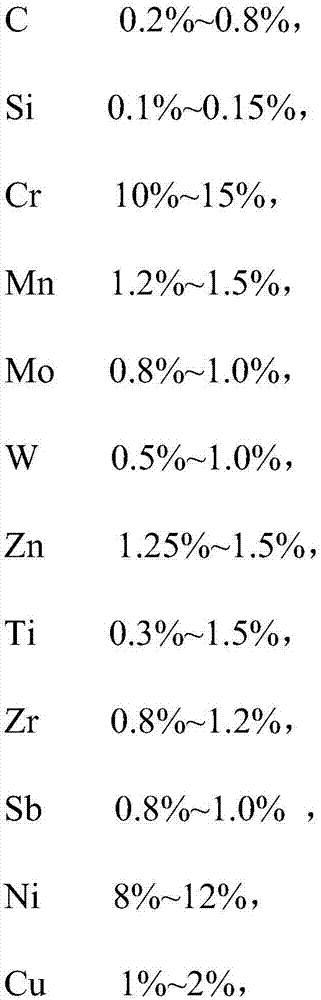

[0029] The preparation method of high-strength tensile type cold-rolled steel strip of the present invention is as follows,

[0030] a. Refining: After refining the above-mentioned components, cast them into slabs and remove phosphorus through a phosphorus removal device;

[0031] b. Hot rolling: the dephosphorized slab is heated at 1000°C to 1300°C through a hot coil box, and is pressed into strip steel by a finishing rolling unit for multiple times;

[0032] c. Annealing: Anneal the steel strip. The annealing is divided into three sections. The temperature of the first section is 800 ° C ~ 1000 ° C under the protection of nitrogen gas, and the temperature of the second section is 500 ° C ~ 800 ° C under the protection of nitrogen gas. The temperature of the third stage is 300℃~500℃, and it is cooled in the air state;

[0033] d. Electrolysis: Place the cooled strip steel in an electrolytic cleaning tank filled with alkaline electrolyte for electrolysis to remove residual gr...

Embodiment 1

[0040] 0.2% C, 0.1% Si, 10% Cr, 1.2% Mn, 0.8% Mo, 0.5% W, 1.25% Zn, 0.3% Ti, 0.8% Zr, 0.8% Sb , 8% Ni, 1% Cu, and 75.05% Fe are mixed and then refined, and then the slab is refined and dephosphorized by a dephosphorization machine; the dephosphorized slab is heated at 1000°C by a hot coil box , through the finishing rolling unit to carry out multiple pressings into strip steel; the strip steel is annealed, and the annealing is divided into three sections, the first section temperature is 800 ° C, under nitrogen protection, the second section temperature is 500 ° C, under nitrogen protection state, the temperature of the third section is 300 °C, and it is cooled in the air state; the strip steel after cooling is placed in an electrolytic cleaning tank filled with a sodium hydroxide solution with a mass fraction of 15% for electrolysis, and the electrolysis current density is 30 ~40A / dm 3 , for removing the residual grease on the surface of the steel strip; after the strip stee...

Embodiment 2

[0042] 0.5% C, 0.12% Si, 12% Cr, 1.4% Mn, 0.9% Mo, 0.8% W, 1.35% Zn, 0.8% Ti, 1.0% Zr, 0.9% Sb , 10% Ni, 1.5% Cu, and 68.73% Fe are mixed and then refined. After refining into a slab, the phosphorus is removed by a dephosphorization machine; the dephosphorized slab is heated at 1200°C by a hot coil box , through the finishing rolling mill for multiple times to press into strip steel; the strip steel is annealed, and the annealing is divided into three sections, the first section temperature is 900 ° C, under nitrogen protection, the second section temperature is 600 ° C, under nitrogen protection Under normal conditions, the temperature of the third section is 400 ° C, and it is cooled in the air state; the cooled strip steel is placed in an electrolytic cleaning tank with a mass fraction of 15% sodium hydroxide solution for electrolysis, and the electrolysis current density is 35A / dm 3 , for removing the residual grease on the surface of the steel strip; after the strip ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com