Method for controlling reversible transformation of hydrophilic-hydrophobic properties of folded surfaces by strain and application

A wrinkle and affinity technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of inability to control, poor controllability, long preparation cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

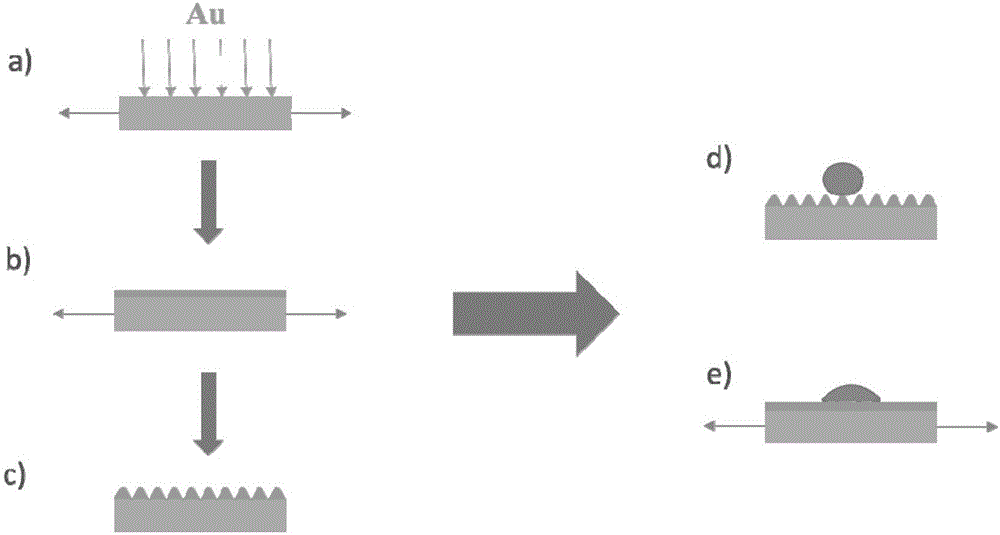

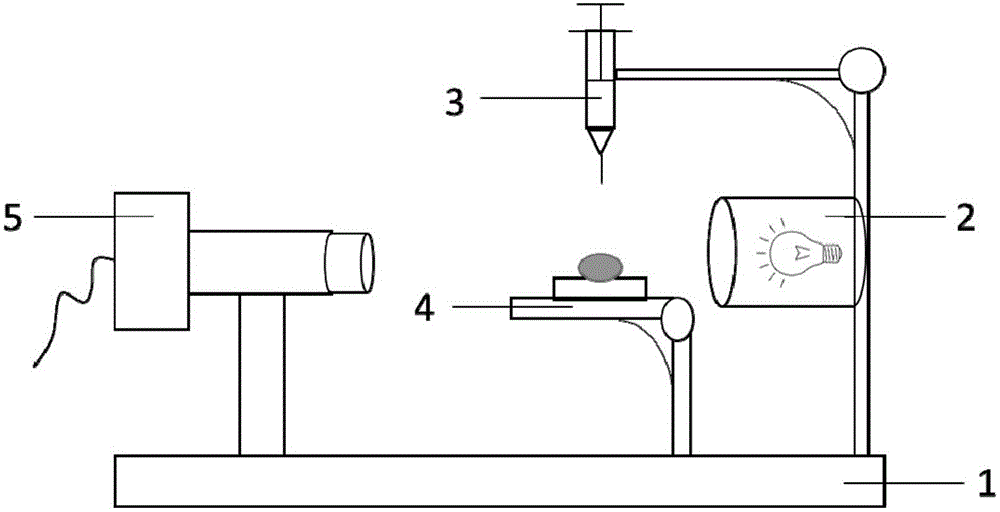

[0011] A method for reversibly changing hydrophilicity and hydrophobicity of wrinkled surfaces through strain regulation, comprising the following steps:

[0012] (1) Stretching the flexible material substrate with a clamp, and depositing a layer of hard film with a thickness of 0.1-0.5 μm on the surface of the flexible material substrate in the stretched state;

[0013] (2) Slowly release the tensile stress on the flexible material substrate on which the hard film is deposited, and obtain a regular wrinkled structure on the surface of the flexible material substrate;

[0014] (3) Use clamps to continuously stretch the wrinkled flexible material substrate step by step, each stretching increment is to extend the wrinkled flexible material substrate by 0.03-0.6cm, and test the contact under each stretching state Angle value, the tensile stress is released slowly at a uniform speed, and the surface hydrophilicity and hydrophobicity are changed to different degrees.

[0015] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com