Operating platform device for laser cladding

An operating platform, laser cladding technology, applied in metal material coating process, coating and other directions, can solve the problems of impact, powder splash, affecting the molding effect, etc., to achieve simple equipment relationship, convenient and simple operation, and improve defect problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

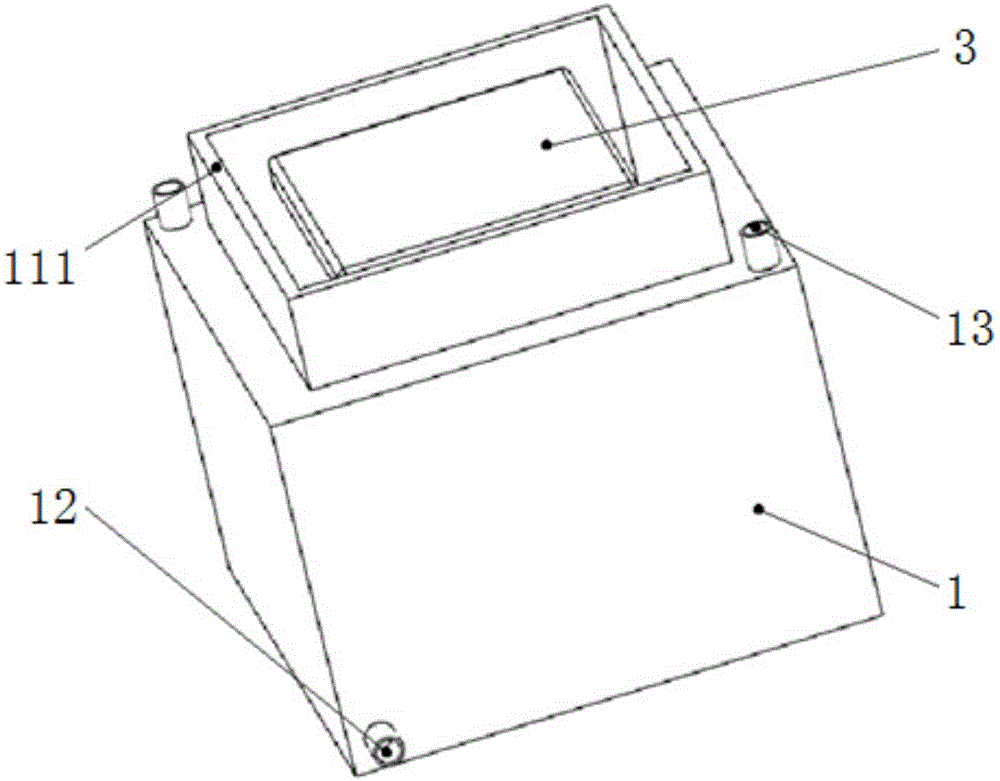

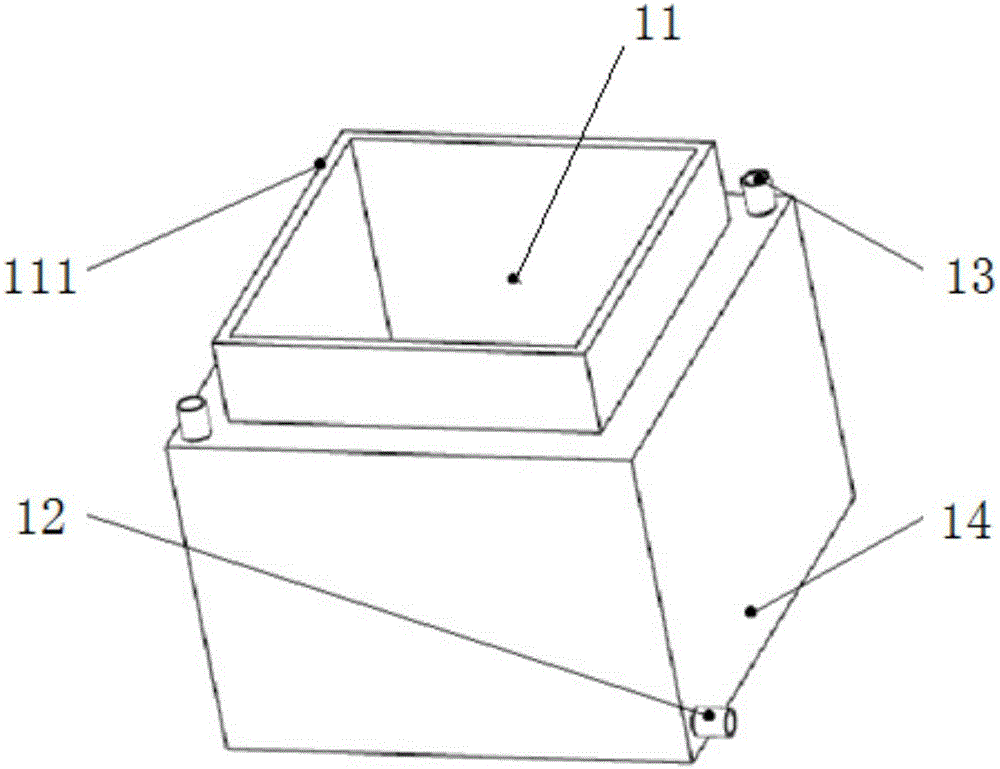

[0047] Such as Figure 1-Figure 5 As shown, an operating platform device for laser cladding includes a lifting platform and a cooling box 1;

[0048] The inner bottom of the cooling box 1 is provided with a partition tube 11 extending to the top of the cooling box 1, the top of the partition tube 11 is open, and the inner wall of the cooling box 1 is connected to the partition A coolant cavity is provided between the outer walls of the tubes 11, and the side wall of the cooling box 1 is provided with a coolant inlet I12 and a coolant inlet II communicating with the coolant cavity, and the top of the cooling box 1 is provided with There are two coolant outlets 13 communicating with the coolant cavity;

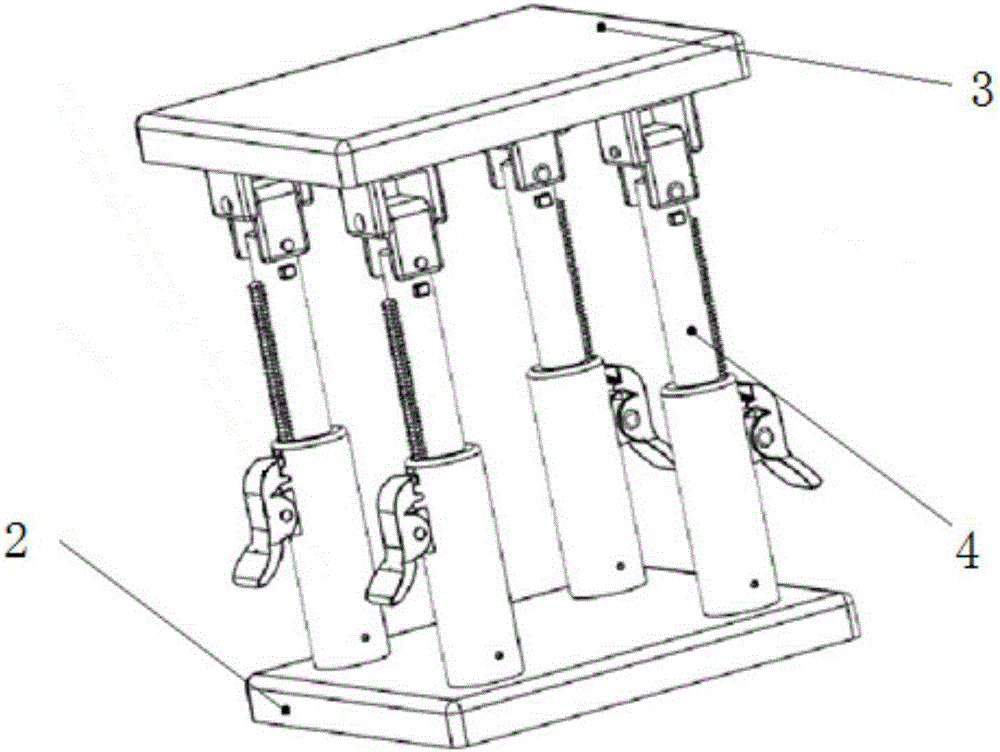

[0049] The lifting platform includes a lower plane 2 attached to the inner bottom of the cooling box 1, a cladding platform 3 and four lifting devices 4 located between the lower plane 2 and the cladding platform 3 ;

[0050]The lifting device 4 includes a support rod I41 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com