Side span cast-in-place section construction structure based on hanging basket and truss-type guide beam and construction method

A construction method and truss-type technology, which is applied in the direction of erecting/assembling bridges, bridges, bridge construction, etc., can solve the problems of high difficulty coefficient of construction platform, high risk of erecting supports, and unbalanced force on side piers, so as to avoid foundation Difficult to handle, easy to popularize and use, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

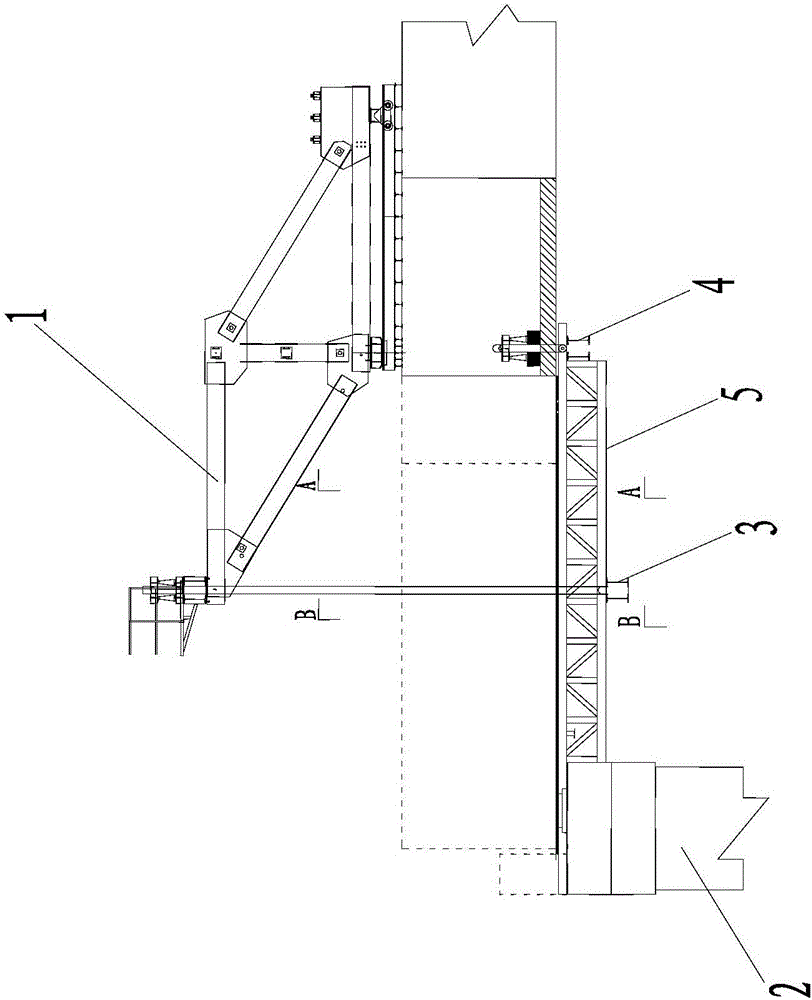

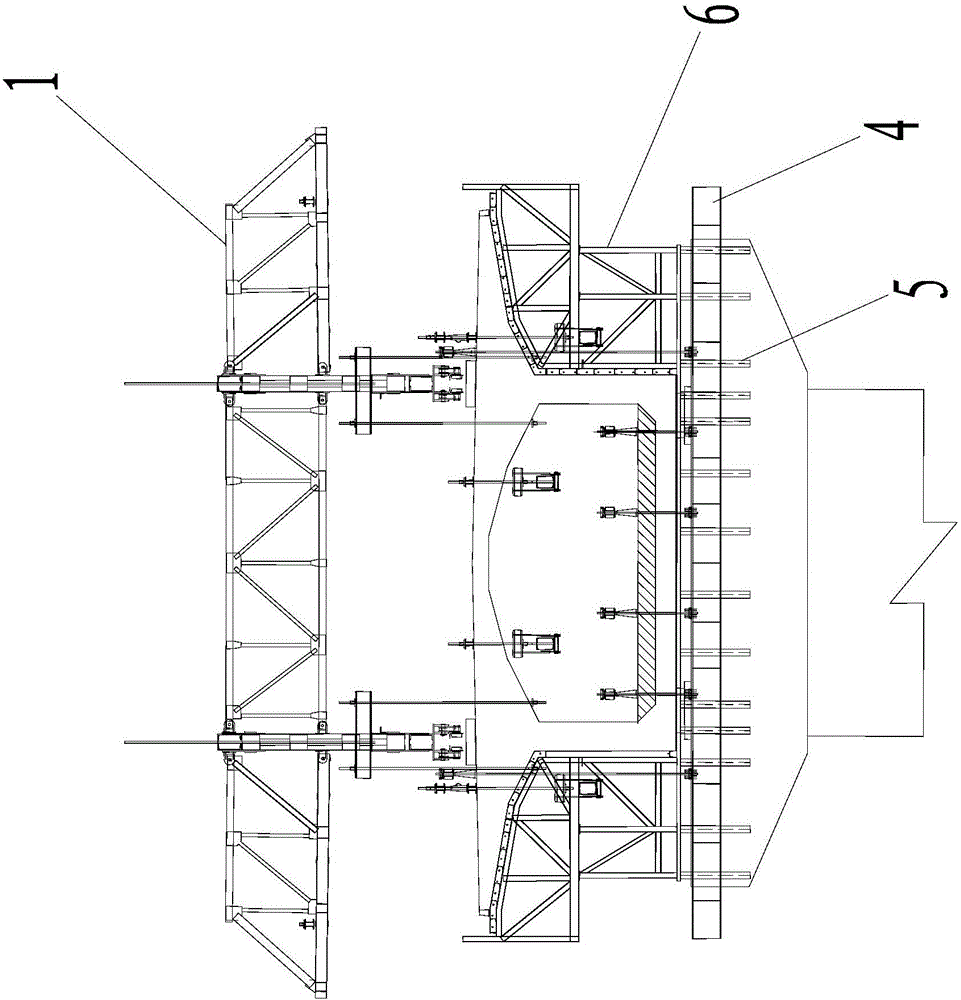

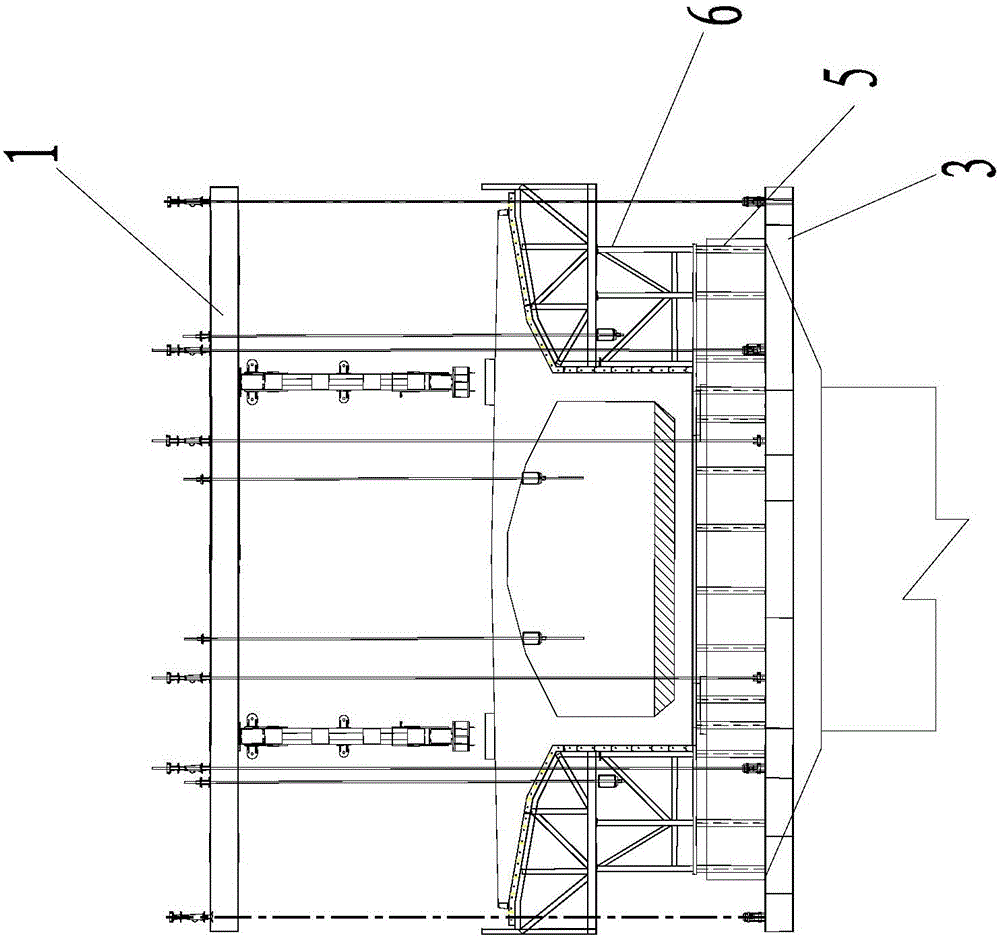

[0066] Such as figure 1 , figure 2 and image 3 As shown, the side-span cast-in-place section construction structure based on the hanging basket and the truss-type guide beam of the present invention includes the hanging basket 1, the rear crossbeam 4 of the hanging basket, and the front crossbeam of the hanging basket located below the rear crossbeam 4 of the hanging basket 3. The truss type guide beam system 5 erected on the front beam 3 of the hanging basket and the rear beam 4 of the hanging basket, and the side formwork systems 6 arranged on both sides above the truss type guide beam system 5, as well as the preloading system and balance counterweight system;

[0067] Such as Figure 4 As shown, the truss-type guide beam system 5 includes multiple unit trusses 5-1 and a bottom form 5-2 arranged above the unit trusses 5-1, and multiple unit trusses 5-1 are arranged side by side. The unit truss 5-1 includes an upper chord 5-1-1 and a lower chord 5-1-2, and a web connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com