Unit curtain wall plate assembly support device and support frame

A supporting device and unitized technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of unsuitable unit components of various width sizes, inconvenient assembly and movement, etc., to achieve assembly production lines, assembly and movement Convenience and improved assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention provides a unitized curtain wall panel assembly support device. The invention has the characteristics of adjustable support distance, suitable for unit plates of various external dimensions, convenient operation and the like.

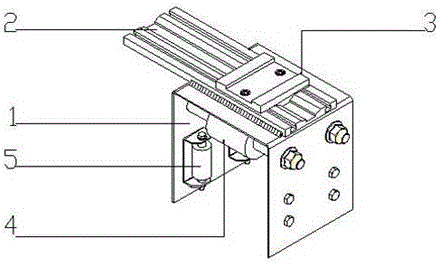

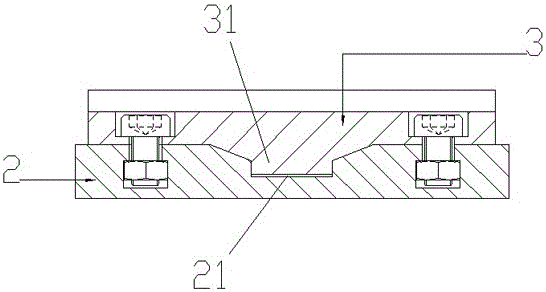

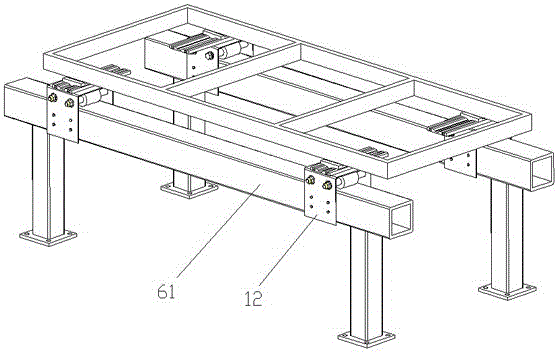

[0018] Such as Figure 1-3 As shown, a unitized curtain wall plate assembly support device includes a fixed plate 1 , an adjusting plate 2 , a supporting plate 3 , rollers 4 and four guide wheels 5 . The fixed plate 1 is made of steel plate with an inverted U-shaped section. The outer side of the wing plate 11 of the fixed plate is welded with the adjusting plate 2. The inner side of the wing plate 11 of the fixed plate 1 is equipped with a roller 4. The roller 4 is provided with a support shaft. The support shaft passes through the The bolts are fixed on the webs 12 on both sides of the fixed plate 1, and the rotation direction is parallel to the wing plate 11; the inner sides of the two webs 12 of the fixed plate 1 are respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com