Method for determining minimum burial depth of complex stratum shield tunnel

A technology of shield tunneling and composite strata, which is applied in tunnels, earthwork drilling, mining equipment, etc., to achieve the effects of simple structure, saving engineering costs, and low construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

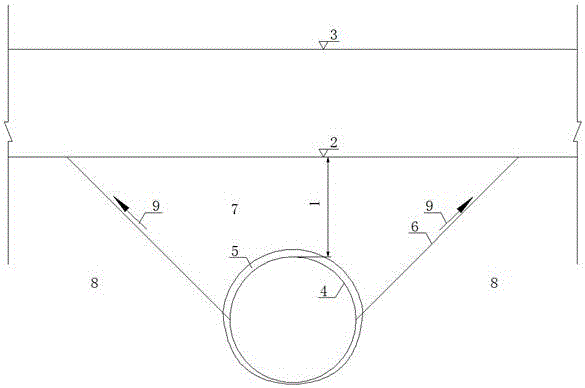

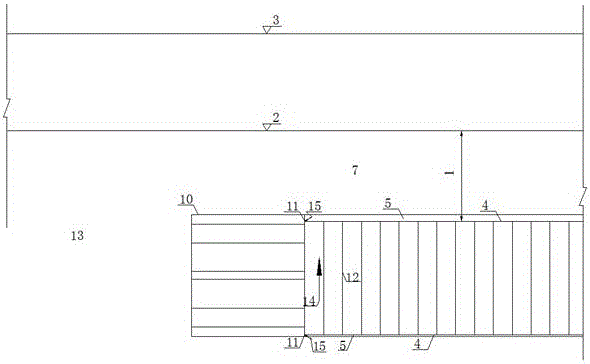

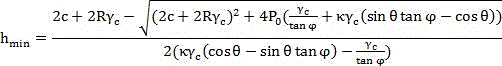

[0032] see as figure 1 and figure 2 As shown, this embodiment adopts the following technical scheme: its construction steps are as follows: according to the structure of the tunnel segment joint 12, determine the maximum shear force it can bear, that is, the joint shear force 14; the joint shear force 14 The relationship between the synchronous grouting filling area 5, the synchronous grouting position 11 and the grouting pressure 15, determine the reasonable pressure standard of the synchronous grouting position 11 as the grouting pressure 15 of tunnel grouting; according to the grouting filling area 5. Synchronous grouting position 11 and grouting pressure 15 are used to calculate the dynamic buoyancy of shield tunnel 4; the sum of dynamic buoyancy and static buoyancy is the ultimate buoyancy during tunnel construction; the buoyancy affects the shear of the overlyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com