Emission aftertreatment system and method applied to gasoline engine

A gasoline engine and treatment method technology, applied in exhaust treatment, engine components, combustion engines, etc., to achieve the effect of improving treatment capacity and reducing emission of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

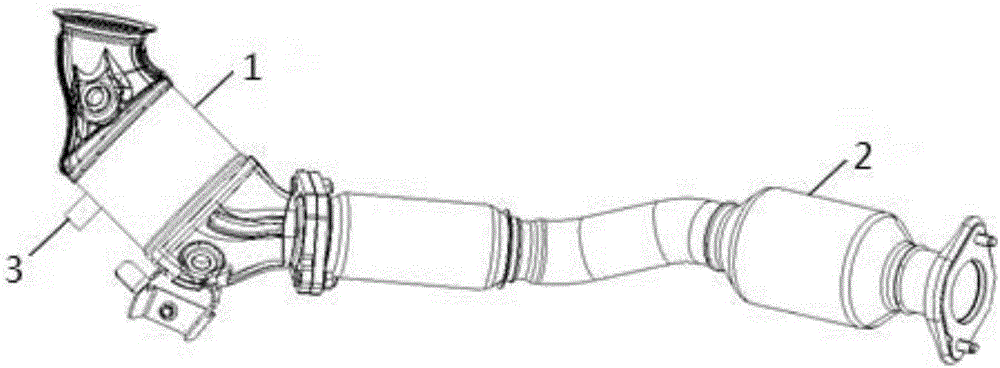

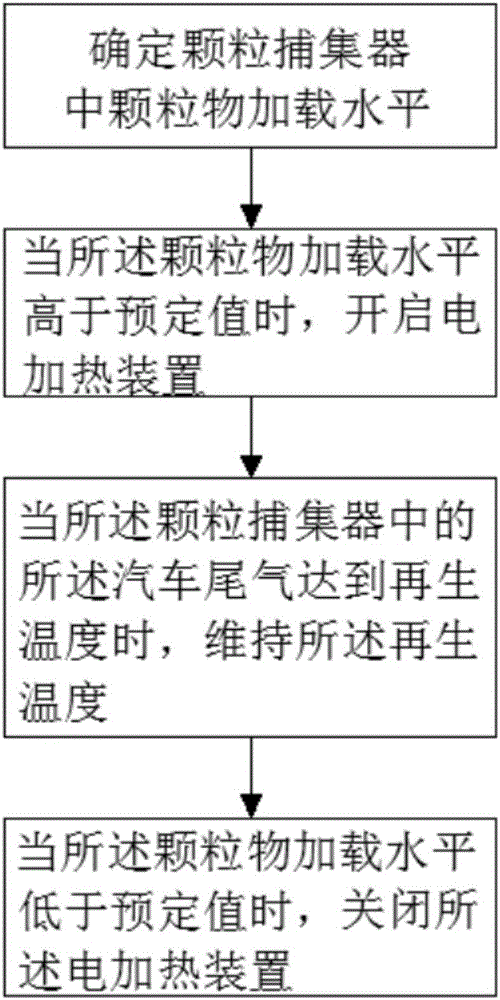

[0030] figure 1 It is a schematic layout diagram of an exhaust after-treatment system according to an embodiment of the present invention, such as figure 1 As shown, an exhaust aftertreatment system applied to a gasoline engine includes a three-way catalyst 1, a particle trap 2, an electric heating device 3, and a control module (not shown in the figure). The three-way catalyst 1 is installed behind the exhaust manifold in the engine compartment, and is used to convert harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides discharged from automobile exhaust into harmless carbon dioxide, water and carbon dioxide through oxidation and reduction. Nitrogen. The carrier in the three-way catalytic converter 1 is a metal carrier. The particle trap 2 is installed at the outlet end of the three-way catalytic converter 1, and is used to convert the remaining harmful gas and capture the particulate matter in the automobile exhaust. The filter element of the particle tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com