Design method for landing gear buffer based on variable oil hole of oil return cavity

A technology of landing gear buffer and design method, which is applied in the directions of landing gear, shock absorber, shock absorber, etc., can solve problems such as non-variable damping, and achieve the effects of flexible design, increased power absorption, and simple and effective measures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

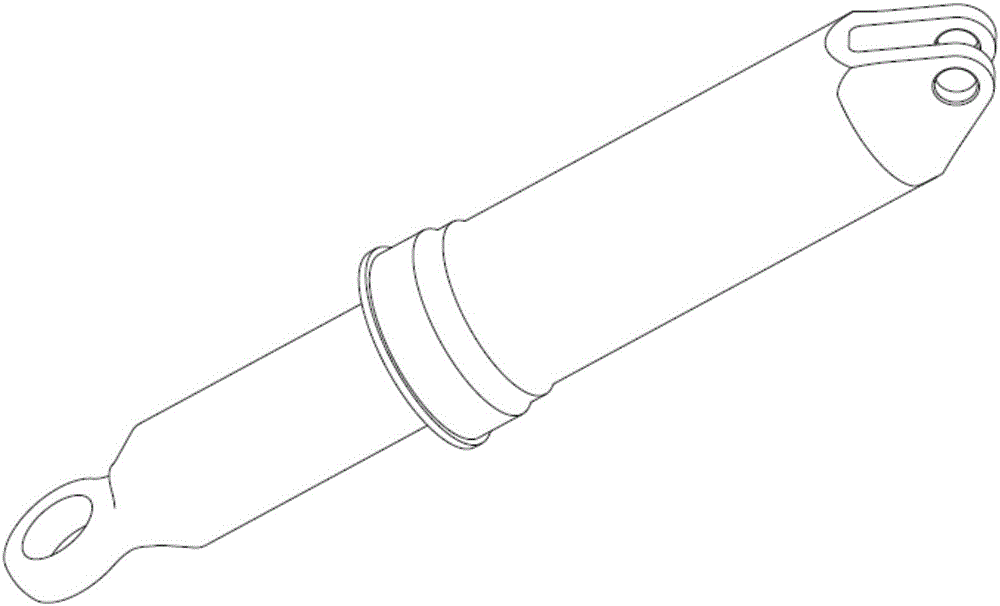

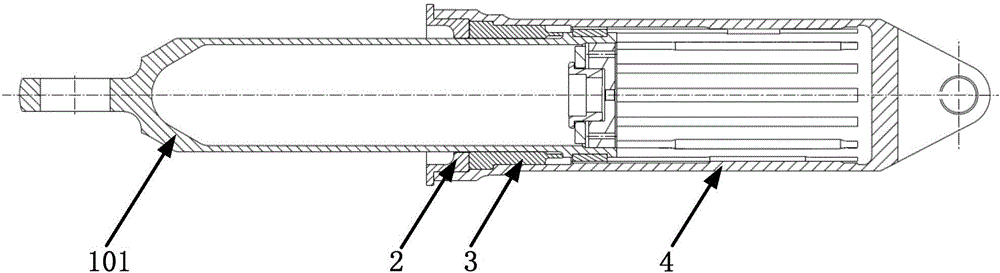

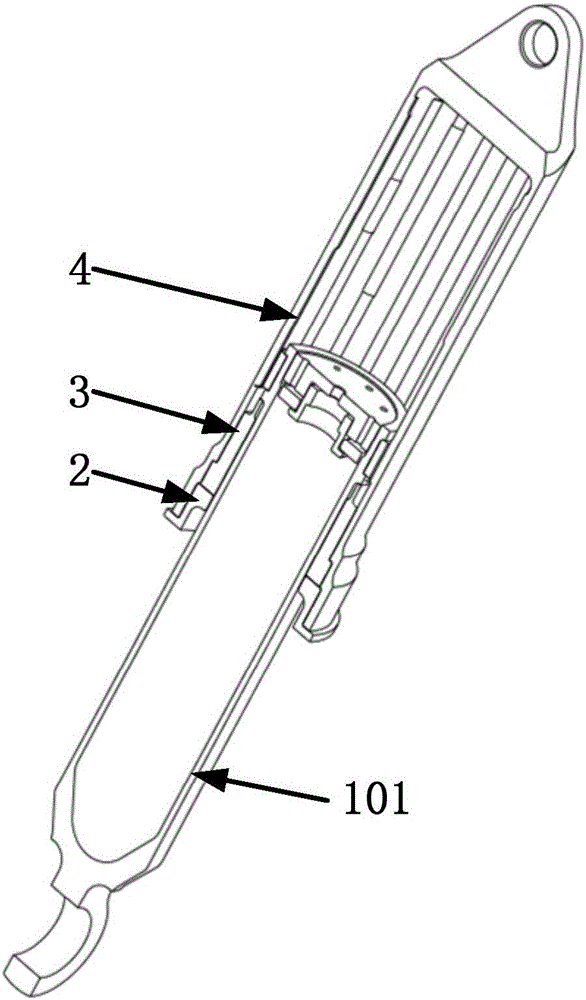

[0032] The present invention is based on the design method of the landing gear buffer of the oil return chamber and the oil change hole, see Figure 1-3 , the buffer is composed of an outer cylinder 4, a piston rod assembly 1, a lower bushing 3, and an end cover 2, the four are coaxial, a part of the piston rod assembly 1 is inside the outer cylinder 4, and a part extends out of the outer cylinder 4, and the lower The shaft sleeve 3 and the end cover 2 restrict the piston rod assembly 1 so that it cannot escape from the outer cylinder 4 . The lower shaft sleeve 3 and the end cover 2 are integrated with the outer cylinder 4 through mechanical connection.

[0033] The inside of the buffer is filled with oil and gas. When the piston rod assembly 1 is not subjected to external load, the buffer is affected by the internal gas pressure and is in a fully extended s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com