Ball screw type ship swinging and vibration reducing supporting device

A technology of ball screw type and vibration damping support, which is applied in the direction of transmission device, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems of engineering practical value limitation, low operation reliability, high cost, etc., and improve the use of Longer service life, improved anti-rolling effect, and reduced maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

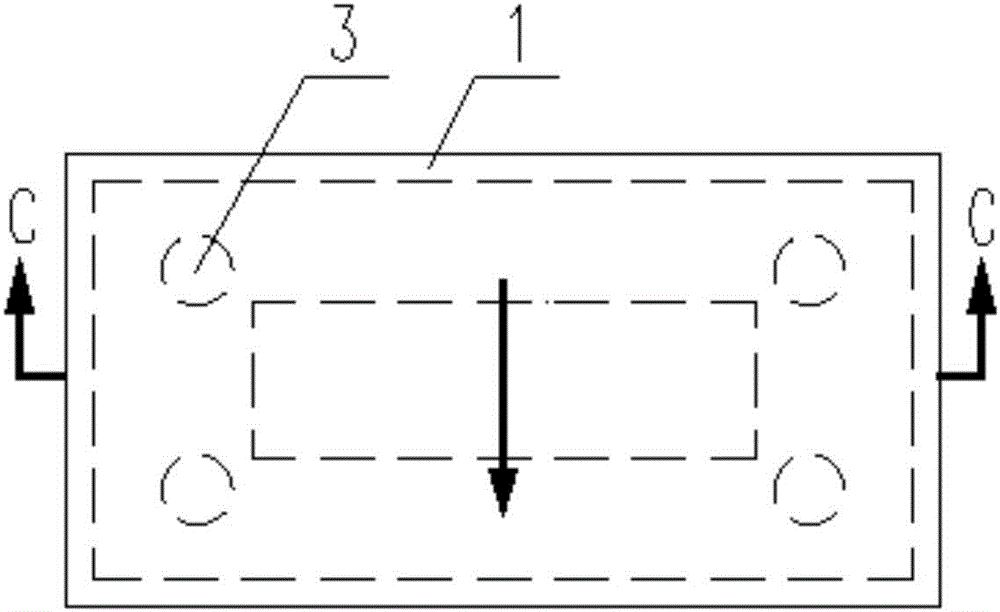

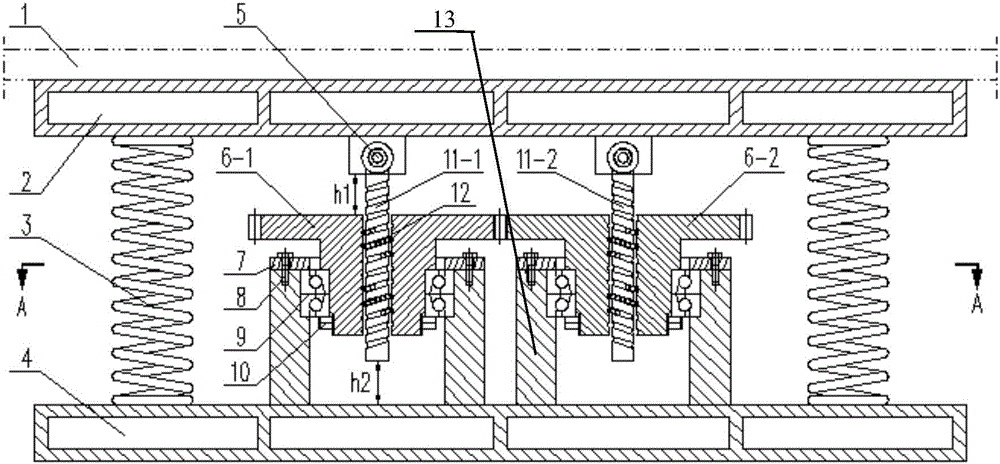

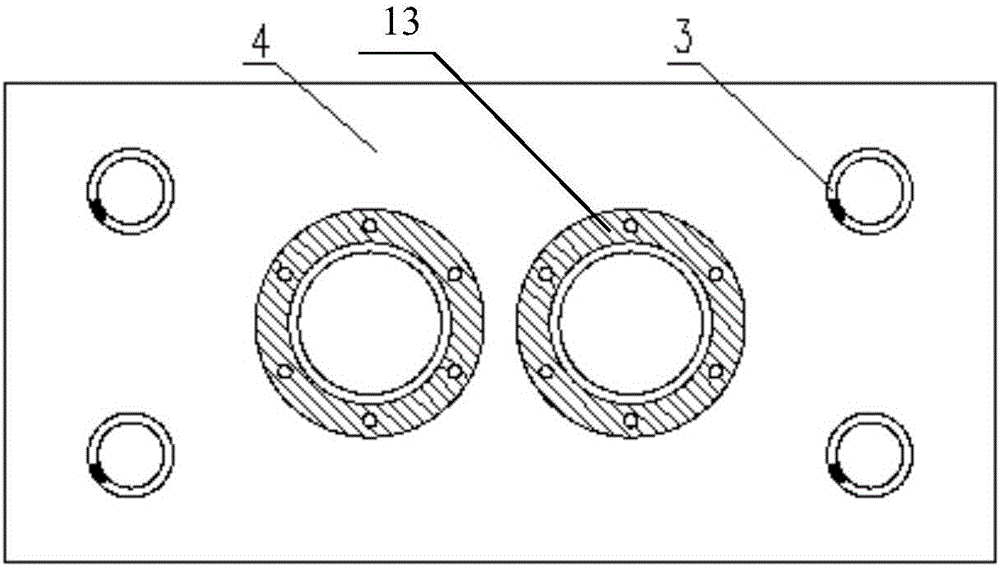

[0028] Such as Figure 1-2 As shown, a ball screw type marine anti-vibration support device includes an upper support frame 2, a spring 3, a lower support frame 4, a ball screw assembly and a flywheel assembly.

[0029] Such as figure 2 As shown, the upper support frame 2 is connected to the mechanical equipment 1, and the lower support frame 4 is fixed to the hull. In this embodiment, the upper support frame 2 and the lower support frame 4 are two identical hollow rectangular plates. The four corners of the rectangular plate are symmetrically provided with springs 3 , one end of the spring 3 is connected to the upper supporting frame 2 , and the other end is connected to the lower supporting frame 4 .

[0030] The lower surface of the upper supporting frame 2 is provided with a rotating support, and the ball screw assembly is rotatably mounted on the rotating supporting frame through the pin shaft 5, and the leading screws 11-1, 11-2 can rotate relative to the upper suppor...

Embodiment 2

[0040] In this embodiment, the thread directions of the two screw screws 11-1, 11-2 of the ball screw assembly are the same, and the flywheels 6-1, 6-2 are connected to each other through the synchronous gear belt 14, so that the flywheels 6-1, 6 The steering of -2 is in the same direction. In this embodiment, the other structural features are the same as those in Embodiment 1 except that the screw thread direction of the lead screw 11-1, 11-2 and the way of cooperation of the flywheel 6-1, 6-2 are different from Embodiment 1.

[0041] In this embodiment, when the mechanical equipment 1 swings counterclockwise relative to the forward direction 13 of the ship, the upper supporting frame 4 swings counterclockwise, driving the right screw 11 to move upward and the left screw 11 to move downward. The left lead screw 11 that moves downward drives the left flywheel 6 to rotate counterclockwise, the left flywheel 6 that rotates counterclockwise drives the right flywheel 6 to rotate c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com