Anti-overpressure-explosion natural gas pipeline

A natural gas pipeline, anti-overpressure technology, applied in pipeline systems, pipes, pipe components, etc., can solve problems such as inability to accurately relieve pressure, low spring control accuracy, and inability to determine continued transportation of branch pipes, reducing construction area, Accurate timing of pressure relief and the effect of reducing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

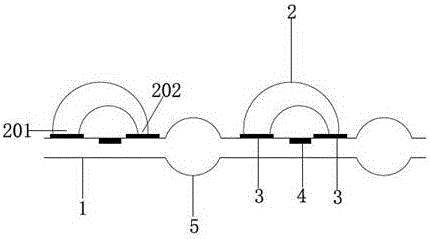

[0026] An anti-overpressure explosion natural gas pipeline, comprising a main pipeline 1, and a plurality of branch pipelines 2 are also arranged on the main pipeline 1; the inlet end 201 and the outlet end 202 of the branch pipeline 2 are connected to the main pipeline 1; The branch pipeline 2 is arc-shaped; the inlet port 201 and the outlet port 202 are provided with a solenoid valve 3 for controlling the switch of the inlet port 201 and the outlet port 202; the inside of the main pipeline 1 is provided with a pressure sensor 4; the pressure The sensor 4 is located on the same side of the branch pipe 2; the pressure sensor 4 is connected to the solenoid valve 3; and the branch pipe 2 is located on the same plane.

[0027] The present invention uses the pressure sensor 4 to detect the gas concentration in the main pipeline 1. When the gas concentration exceeds the warning line, the electromagnetic valve 3 is opened, and the natural gas in the main pipeline 1 is diverted and di...

Embodiment 2

[0029] An anti-overpressure explosion natural gas pipeline, comprising a main pipeline 1, and a plurality of branch pipelines 2 are also arranged on the main pipeline 1; the inlet end 201 and the outlet end 202 of the branch pipeline 2 are connected to the main pipeline 1; The branch pipeline 2 is arc-shaped; the inlet port 201 and the outlet port 202 are provided with a solenoid valve 3 for controlling the switch of the inlet port 201 and the outlet port 202; the inside of the main pipeline 1 is provided with a pressure sensor 4; the pressure The sensor 4 is located on the same side of the branch pipe 2; the pressure sensor 4 is connected to the solenoid valve 3; and the branch pipe 2 is located on the same plane.

[0030] A pressure relief chamber 5 is provided near the outlet end 202 of the branch pipe 2; the pressure relief chamber 5 is spherical in shape;

[0031] The present invention uses the pressure sensor 4 to detect the gas concentration in the main pipeline 1. When...

Embodiment 3

[0034] An anti-overpressure explosion natural gas pipeline, comprising a main pipeline 1, and a plurality of branch pipelines 2 are also arranged on the main pipeline 1; the inlet end 201 and the outlet end 202 of the branch pipeline 2 are connected to the main pipeline 1; The branch pipeline 2 is arc-shaped; the inlet port 201 and the outlet port 202 are provided with a solenoid valve 3 for controlling the switch of the inlet port 201 and the outlet port 202; the inside of the main pipeline 1 is provided with a pressure sensor 4; the pressure The sensor 4 is located on the same side of the branch pipe 2; the pressure sensor 4 is connected to the solenoid valve 3; and the branch pipe 2 is located on the same plane.

[0035] A pressure relief chamber 5 is provided near the outlet end 202 of the branch pipe 2; the pressure relief chamber 5 is spherical in shape;

[0036] The diameter of the branch pipeline 2 is greater than or equal to the diameter of the main pipeline 1 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com