Broad-width large-shell stainless steel hollow profile and manufacturing technology thereof

A kind of stainless steel and stainless steel plate technology, applied in the direction of slender components, building components, etc., can solve the problems of complex process, low efficiency, long cycle, etc., to achieve the effect of simple process, good environmental protection and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

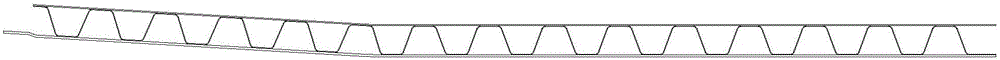

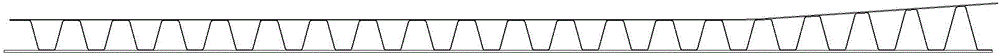

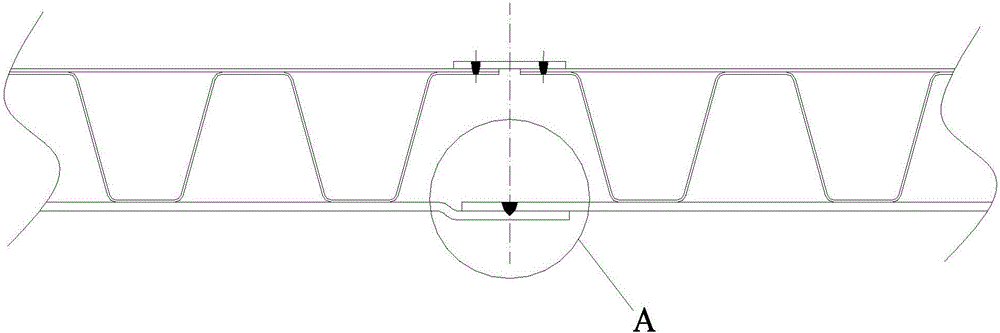

[0024] like Figure 1 to Figure 3 As shown, the cross-sectional shape of the wide and long thin-shell stainless steel hollow section of the present invention can be a flat plate structure of equal thickness or an arc-shaped bent plate structure with a radian of 25° or less and a radius of 500 mm or more, or a variable thickness. section structure. In order to form a wider structure for the wide and long thin-shell stainless steel hollow profiles, the two sides of the cross-sectional structure are designed as plug-in interfaces A, and two or more wide and long thin-shell stainless steel hollow profiles are plugged in pairs in the width direction. , connected by laser welding or other welding methods into a wider stainless steel shell profile structure.

[0025] The wide-width long thin-shell stainless steel hollow profile of the present invention is composed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com