Mass transfer enhancing type modular adsorption bed

An adsorption bed and modular technology, applied in the field of adsorption beds, can solve the problems of poor pressure bearing capacity of the adsorption bed, increase the total heat capacity of the adsorption bed, and affect the performance of the system, so as to reduce metal consumables, reduce the total heat capacity, and strengthen the transmission hot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

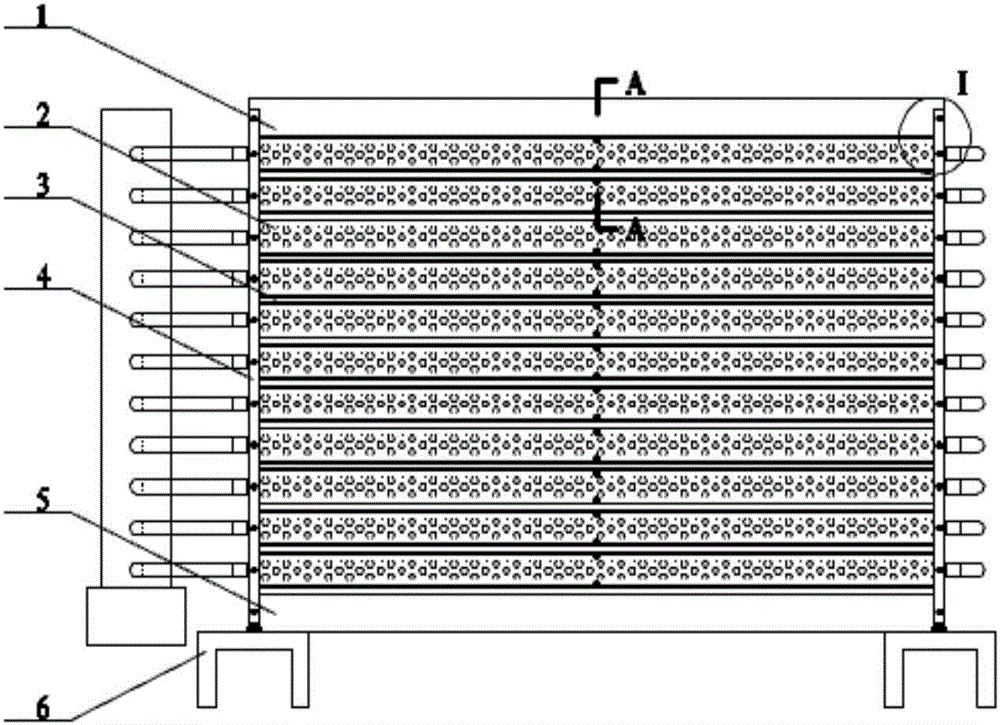

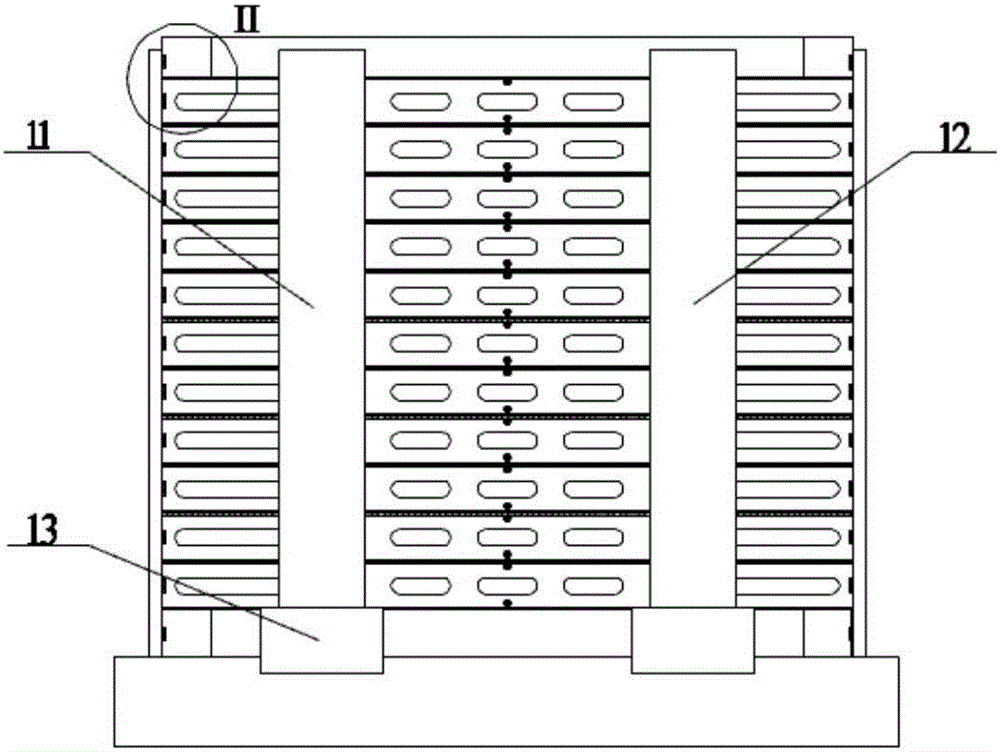

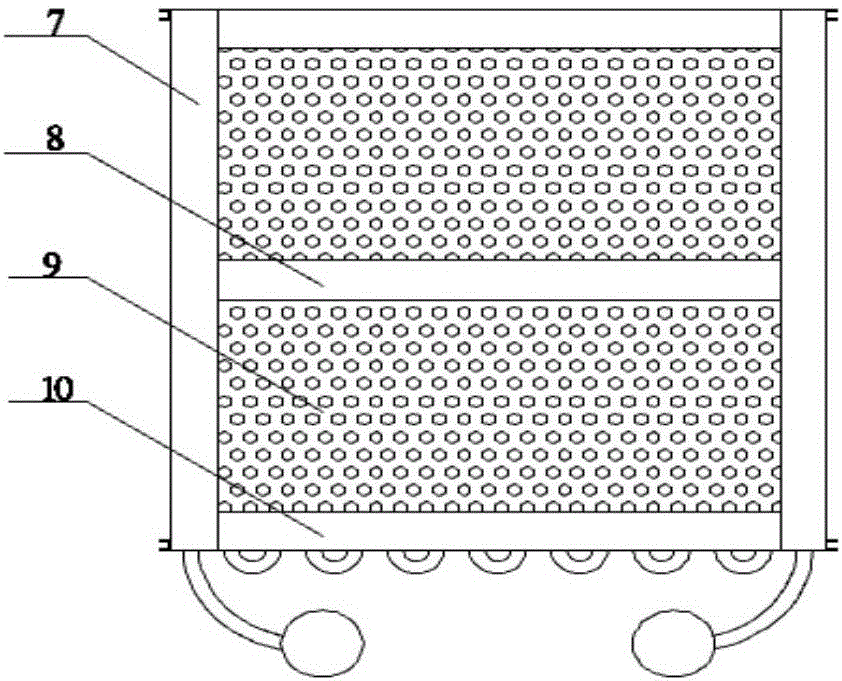

[0022] As shown in the accompanying drawings, the mass transfer-enhanced modular adsorption bed of the present invention includes two adsorption bed bases 6 arranged in parallel and spaced left and right, and a plurality of coil units 2 are horizontally stacked up and down sequentially. The tube unit 2 includes fins 17, in which heat exchange tubes 16 are coiled, the gaps between the fins 17 are filled with adsorbent, and the fins 17 are covered with wire mesh 19. A limiting perforated plate 9 is respectively installed on the upper and lower surfaces of the wire mesh, a limiting channel steel 8 is arranged in the middle of the limiting perforated plate 9, and a limiting channel steel 8 is installed on the front and rear sides of the fins 17 respectively. Groove-shaped side perforated plates 7 are provided, and groove-shaped fin maintenance st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com