Vehicle-mounted type heat storage and supply device and work method thereof

A heat supply device and heat device technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as long charging and discharging time, difficult handling, and low safety performance of energy storage materials, and achieve Improve heat supply efficiency, increase heat exchange efficiency, and improve the effect of heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

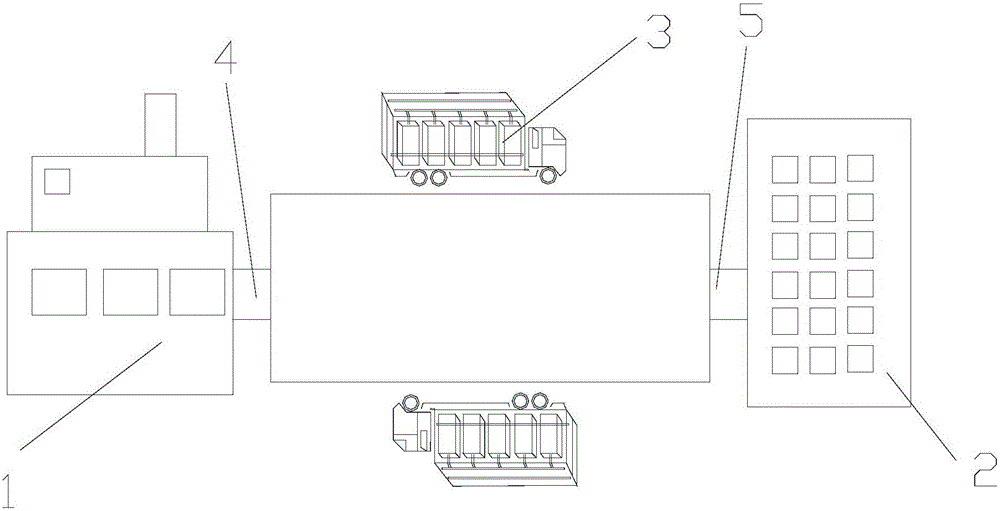

[0036] see figure 1 , the vehicle-mounted heat storage and heating device of this embodiment includes a heat charging and heat exchanging device 4, a heat transport device 3 and a heat releasing heat exchanging device 5, the heat charging and heat exchanging device 4 is arranged at the industrial heat source 1, and the heat releasing and heat exchanging device 5 is set at heat demand user 2. Industrial heat sources mainly include enterprises with high energy consumption, such as steel industry, cement industry, metal processing industry, chemical industry, etc. The waste heat at the industrial heat source 1 is transferred to the heat transport device 3 through the heat transfer medium (water or heat transfer oil) in the waste heat transmission pipeline of the factory, and then the heat transport device 3 travels to the heat demand user 2. The heat transfer medium transfers the heat of the heat transport device 3 to the user-side heat storage device.

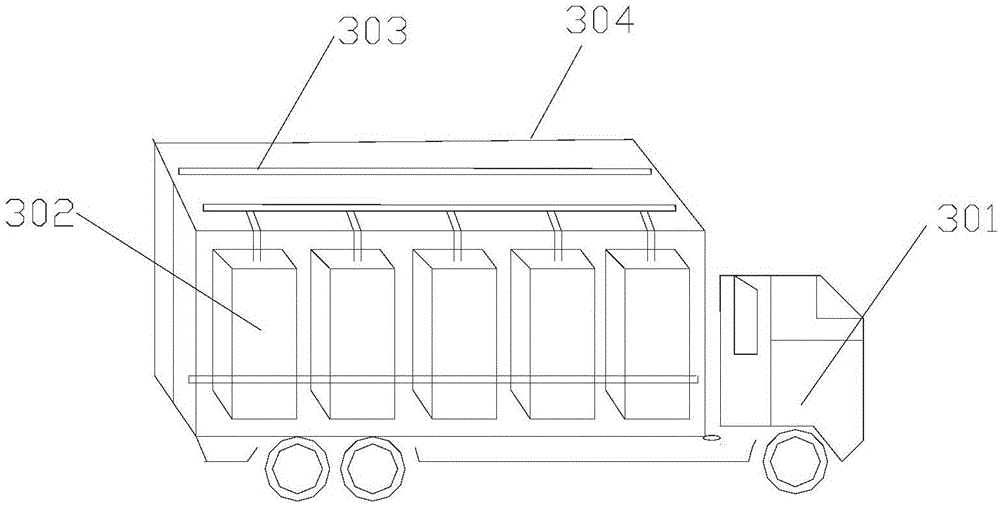

[0037] see figure 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com