Friction force and friction coefficient experiment and measurement device and method

A friction coefficient, measuring device technology, applied in the direction of measuring device, measuring force, using mechanical device, etc., can solve the problems of unbalanced manual force, insufficient accuracy of dynamometer, inconvenient reading, etc., to avoid human error and avoid secondary The effect of high error and speed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Combine below Figure 1-Figure 7 Specific embodiments of the present invention are described in detail:

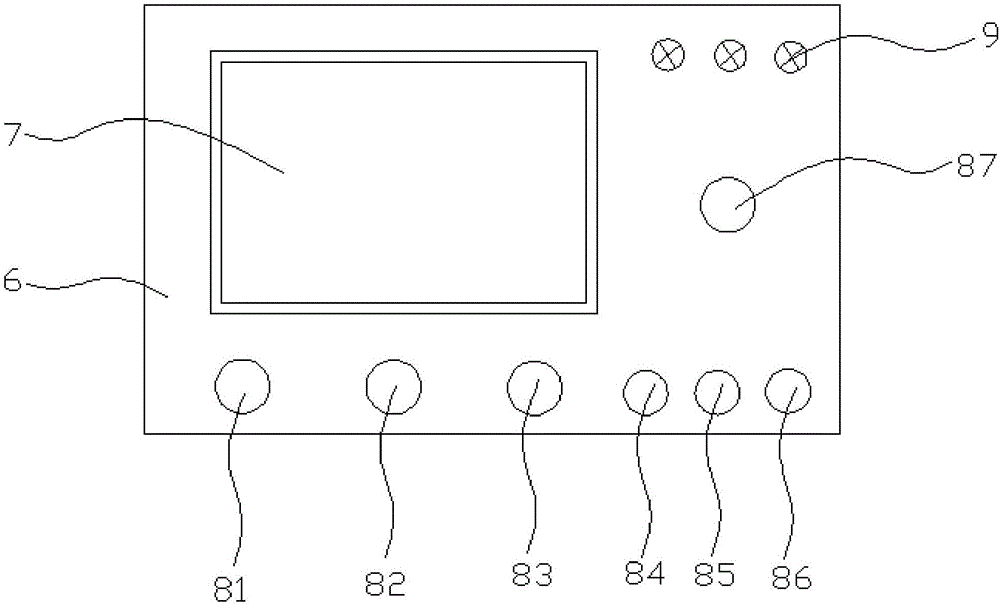

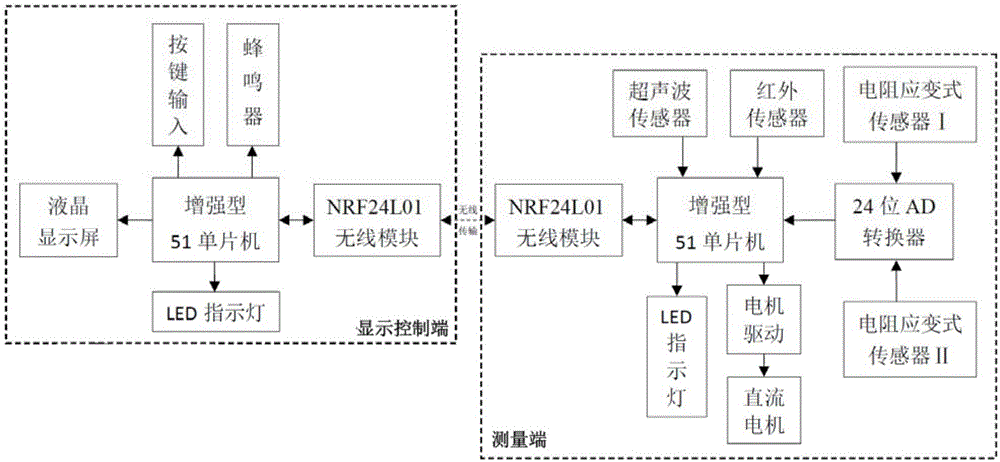

[0050]The invention includes a measurement terminal and a display control terminal, the display control terminal and the measurement terminal are separated from each other, and they perform data communication through wireless.

[0051] It should be noted that although image 3 Only the principle block diagram of the present invention is given in the present invention, but, specific components and parts and the corresponding connection relationship between them are given, according to image 3 Combining with the common knowledge of those skilled in the art, it is easy to implement the detailed circuit connection of the present invention, so details are not repeated here.

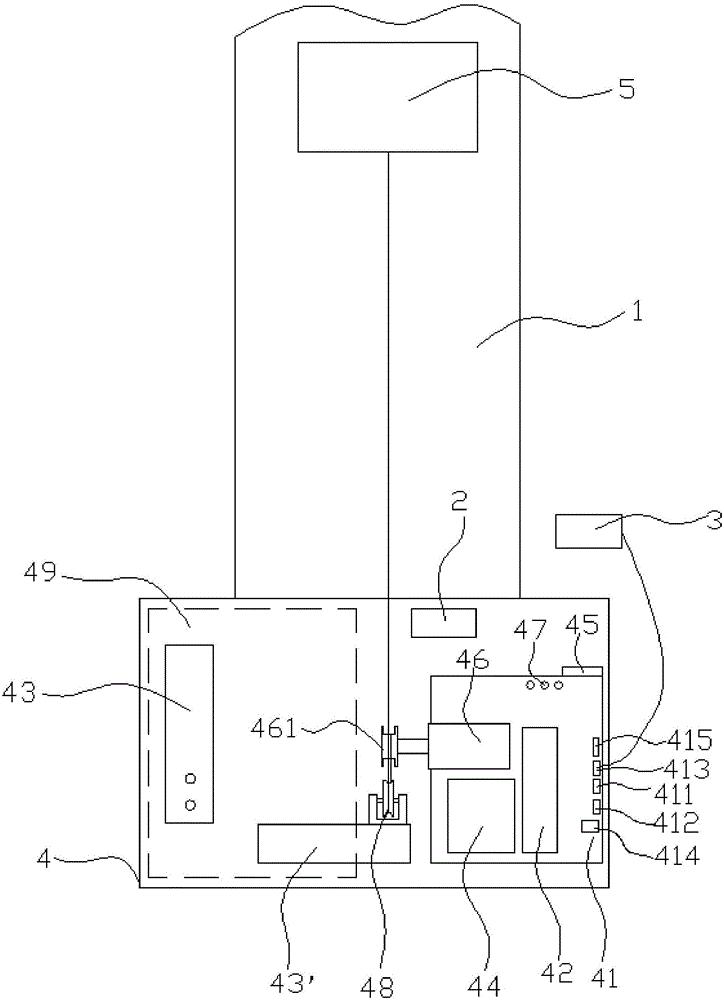

[0052] Such as figure 1 and image 3 As shown, the measuring end includes a friction bearing plate 1, an ultrasonic velocity sensor 2, a motor stop switch 3, a base 4, and a circuit board 41 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com