Backacting shovel hydraulic excavator performance integration characterization method

A hydraulic excavator, excavation performance technology, applied in the direction of mechanically driven excavator/dredger, machine/structural component testing, instruments, etc., can solve the problems of low performance, productivity and service life of excavators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

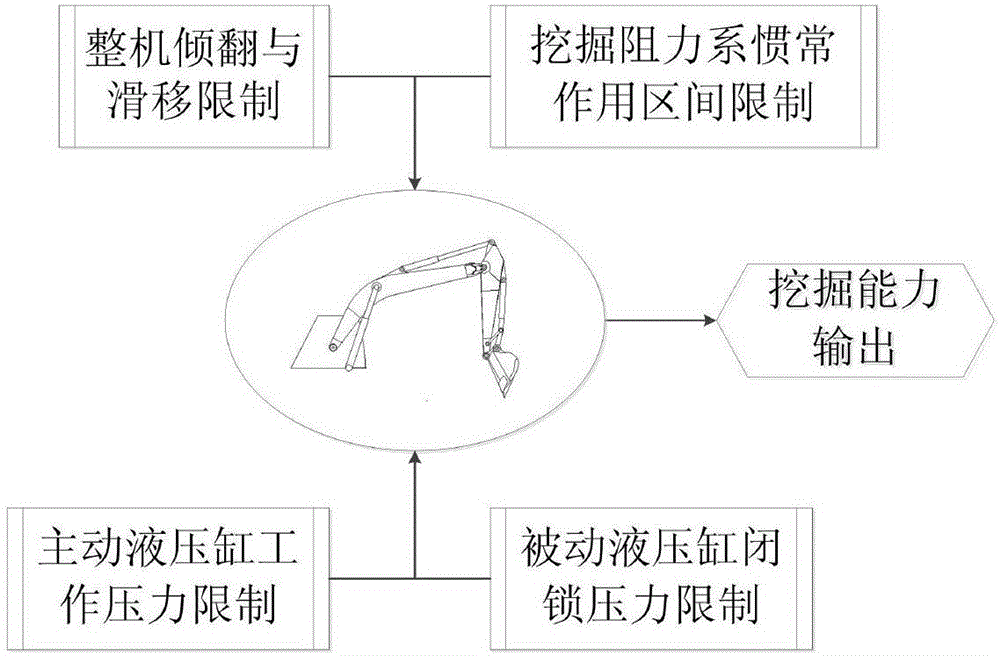

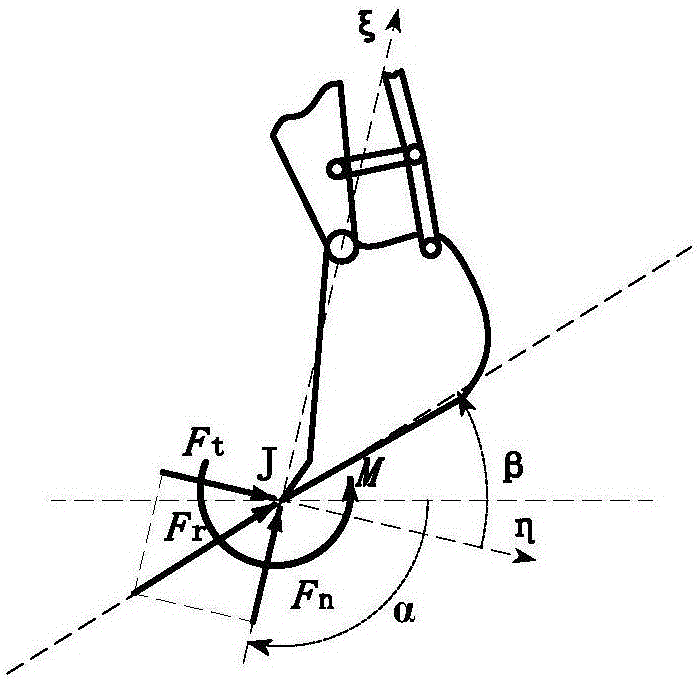

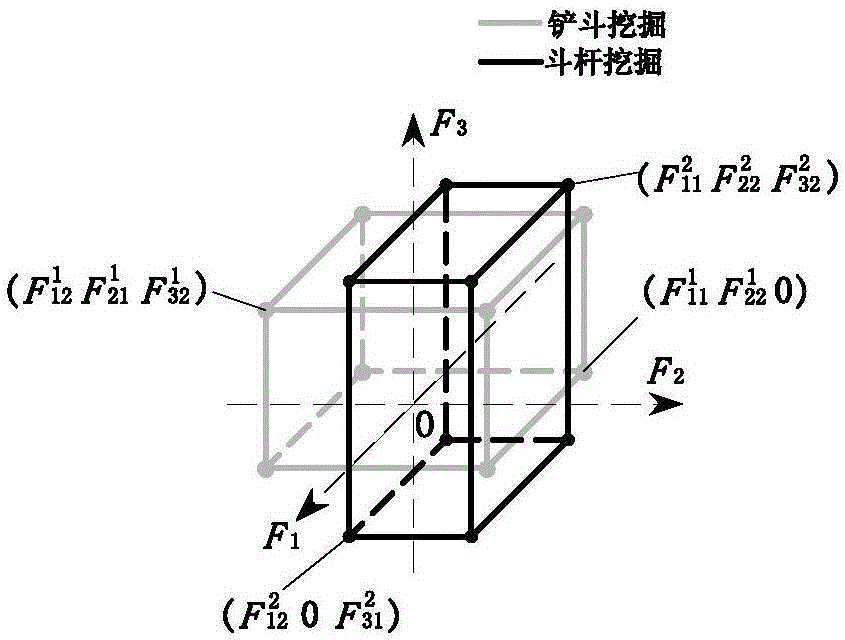

[0078] This embodiment fully considers on the basis of the conventional action range of the excavation resistance system and the restrictive conditions of the whole machine in the excavation process, and proposes a method for comprehensively characterizing the excavator's excavation performance, and uses the method of the present invention to analyze the excavation performance of a certain 36-ton excavator analyzed and evaluated, figure 2 The excavation resistance system is simplified as the tangential excavation resistance F tangent to the tooth tip movement direction t , the normal excavation resistance F perpendicular to the direction of tooth tip movement n and the digging resistance moment M, where, F r is the resultant force of excavation resistance, α is the direction angle of the bucket, and β is the angle between the tangential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com