Air conditioning unit performance detection system

An air-conditioning unit and detection system technology, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems of large power consumption, inaccurate temperature control, and high cost, so as to improve the accuracy of testing and use Good flexibility and power saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

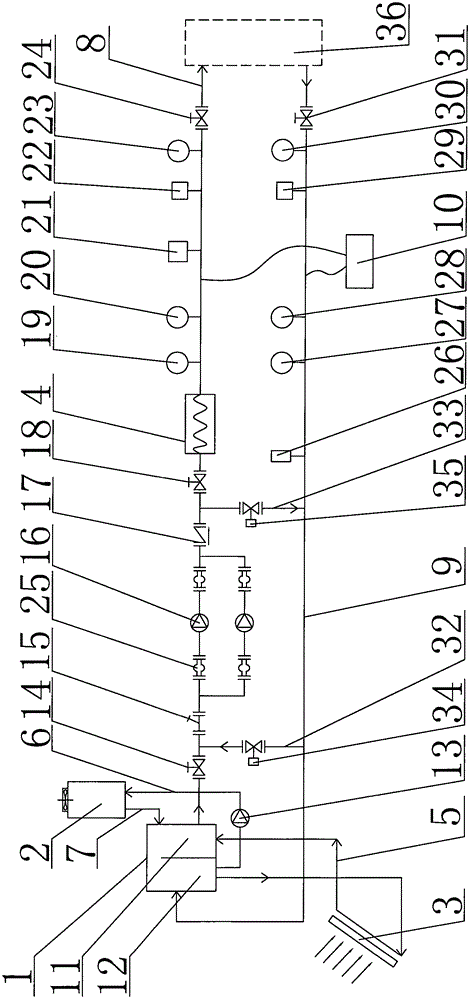

[0010] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution in the embodiment of the present invention will be described below in conjunction with the accompanying drawings in this embodiment (in the figure, two water pumps connected in parallel on the water inlet pipe are taken as an example). Give a clear and complete description.

[0011] Such as figure 1 As shown, the present invention discloses a performance detection system for an air conditioner unit, including a hot and cold separated water tank 1, a cooling tower 2, a solar panel 3, an auxiliary electric heater 4, a connecting pipe 1 5, a connecting pipe 2 6, and a connecting pipe 3 7 , the water inlet pipe 8, the water outlet pipe 9 and the control box 10, the hot and cold separated water tank 1 includes the hot water part 11 and the cold water part 12, and the hot water part 11 and the cold water part 12 are communicated through an external co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap