Fracturing pressure determining device and method for carbon dioxide fracturing device

A carbon dioxide and measuring device technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of lack of special research on carbon dioxide fracturing pressure, which affects the fragmentation effect and energy utilization rate of carbon dioxide phase change fracturing technology, and the measured data is ambiguous And other problems, to achieve the effect of preventing the flying tube phenomenon, preventing the rapid attenuation of energy, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

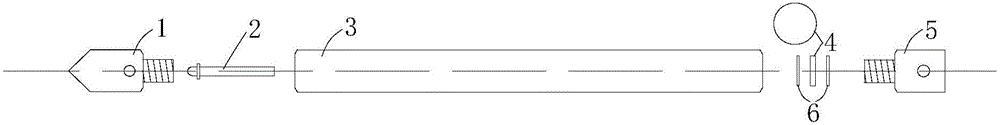

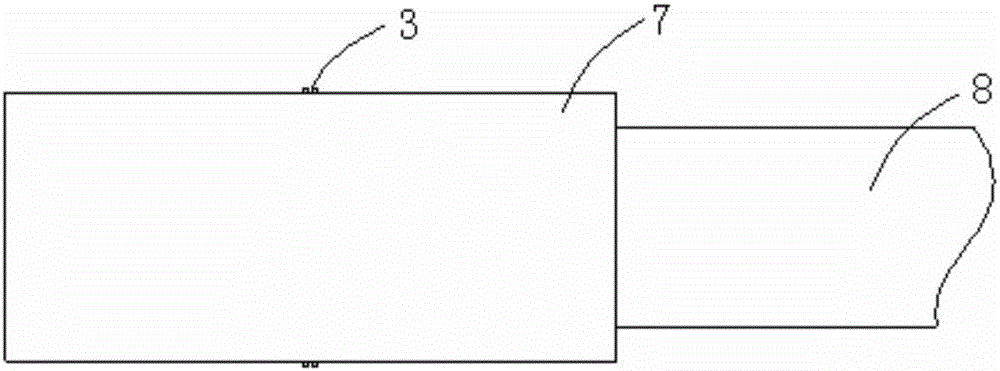

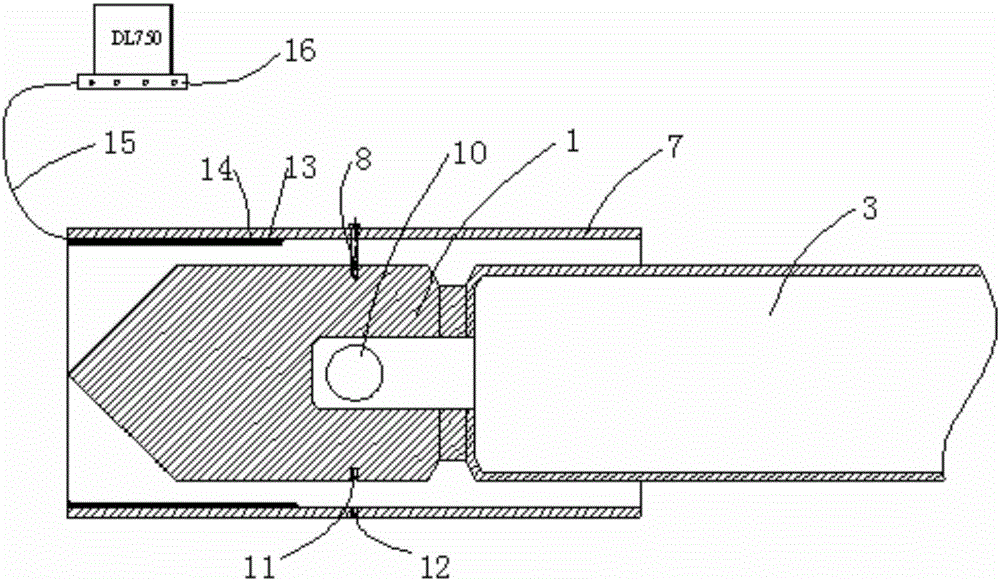

[0038] see figure 2 and image 3 , the cracking pressure testing device of a carbon dioxide cracker in this example is a preferred embodiment of the present invention, specifically including an energy dissipation cover 7, a fixing screw 8, an energy dissipation head 1, a PVDF piezoelectric film sensor 13, a tin foil Adhesive tape 14, signal line 15 and oscilloscope 16.

[0039] Energy release cover 7 adopts seamless steel pipe parts, and fixed cover is contained in figure 1 On the energy-discharging head 1 of the cracker, two energy-discharging holes 10 are arranged at intervals of 180° on the same circumference of the energy-discharging head 1, and the high-pressure gas inside the cracker enters from the two energy-discharging holes 10 In the energy-discharging cover 7, an instantaneous impact is formed on the inside of the energy-discharging cover 7, and then the pressure is released from the openings at both ends of the energy-discharging cover 7.

[0040] The energy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com