Nondestructive testing method of three-dimensional shape and stress characteristics of internal defects of metal welding seam

A technology of internal defects and three-dimensional topography, applied in measurement devices, instruments, material analysis using radiation, etc., can solve problems such as inability to guarantee the accuracy of the model, infeasibility, etc., to save manpower, material resources and time, ensure accuracy, Guaranteed Integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

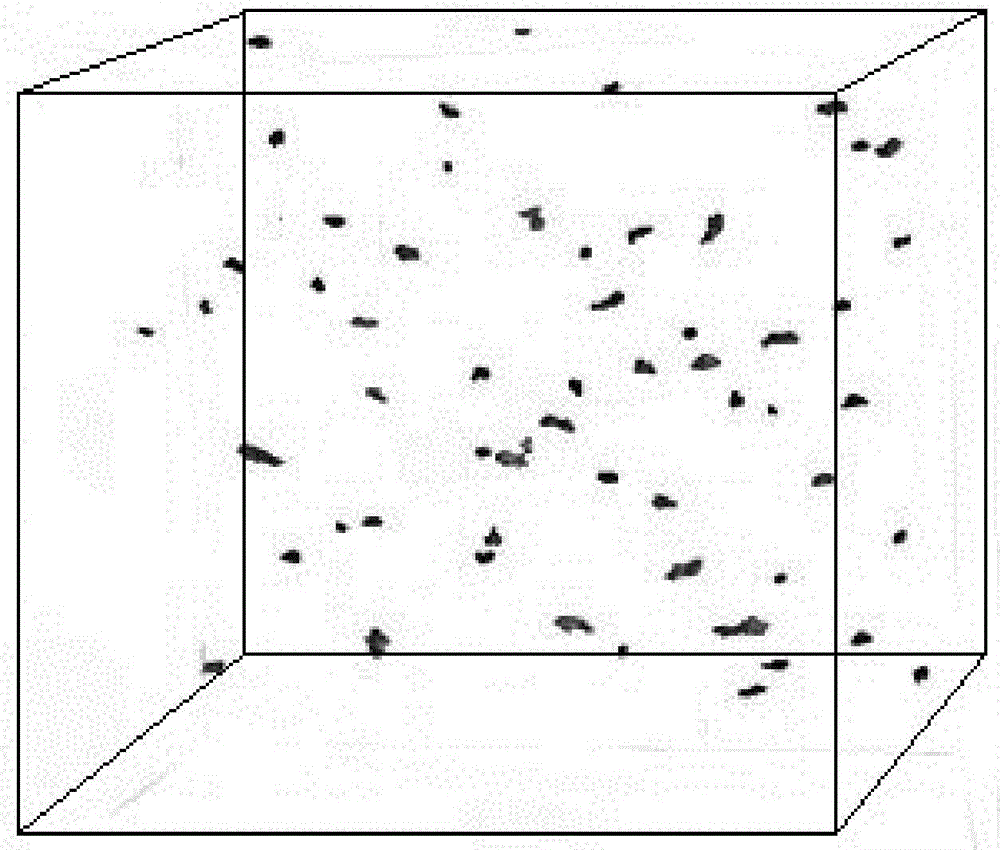

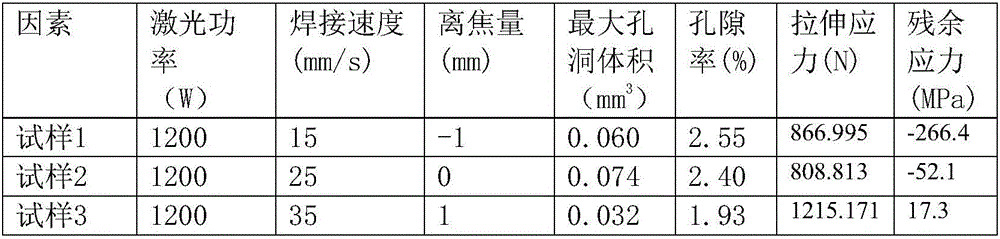

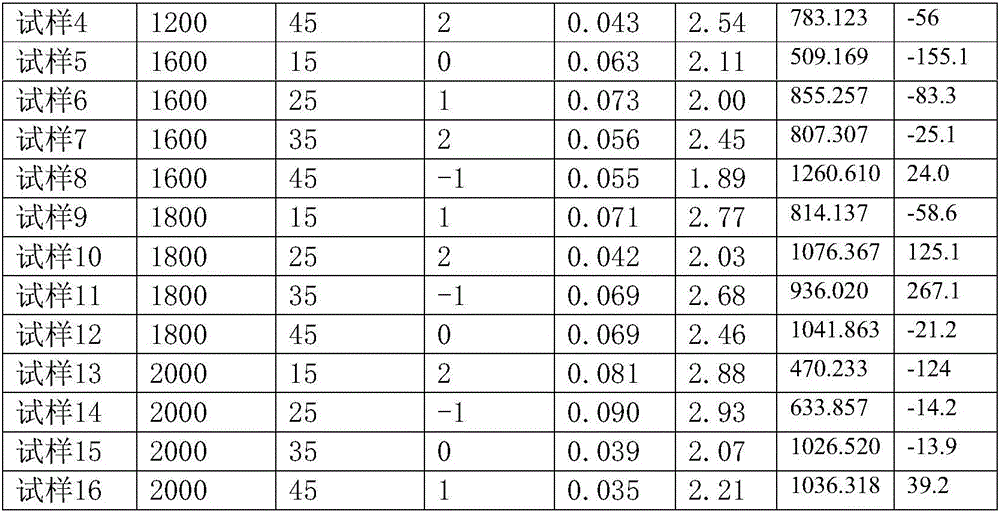

[0018] A specific embodiment of the present invention is a method for detecting internal defects formed by dissimilar metal welds, especially for non-destructive testing of the three-dimensional shape and stress characteristics of the internal defects. The detection method is mainly composed of X-ray computed tomography scanner, dissimilar metal welding sample, VG Studio MAX software, and ansys software; the detector type of X-ray computed tomography scanner is Y.XRD 0820, and the number of detector units is 1024, the number of pixels is 1024×1024. The shape of the dissimilar metal welding sample is arbitrary, and generally it is a flat cuboid, and the size should not be too large, because the smaller the size, the higher the resolution of the three-dimensional reconstruction image. The analysis software used VG Studio MAX2.0 for data processing. The finite element analysis software uses hypermesh and ansys software for analysis and processing.

[0019] Next, an embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com