Thermal loss type air velocity sensor and preparation method and detection method thereof

A wind speed sensor and heat loss technology, which is applied in the direction of measuring fluid velocity by using thermal variables, can solve the problems of reducing the reliability of the sensor and the bonding wire is easy to break, so as to achieve front wireless heating and wireless temperature measurement, improve sensitivity, reduce The effect of power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

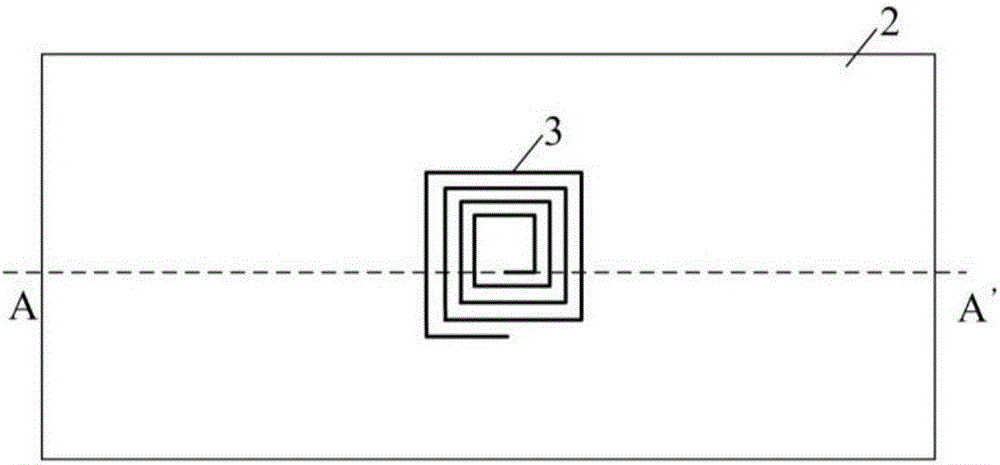

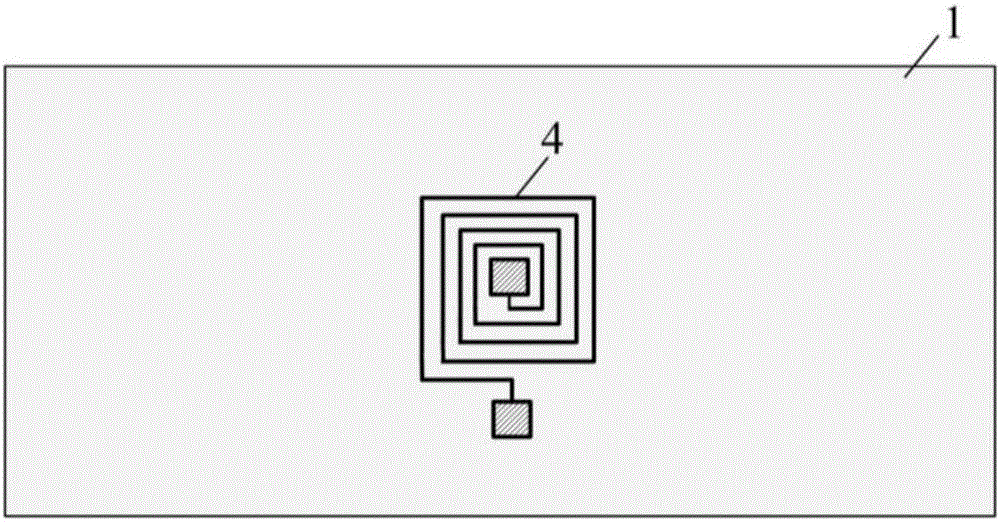

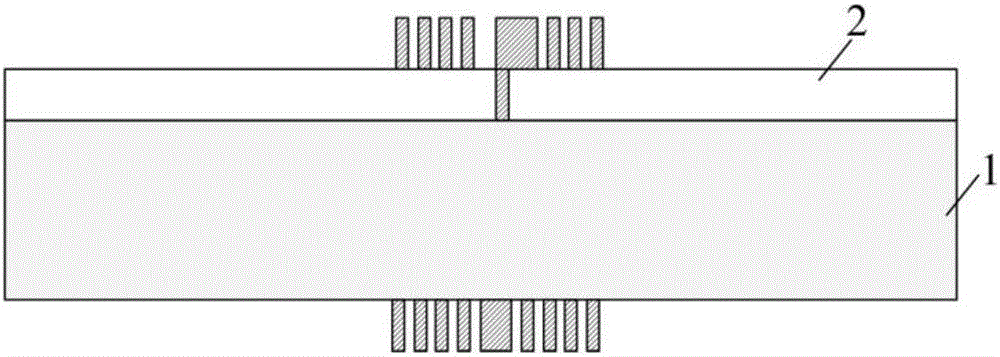

[0026] see figure 1 , figure 2 with image 3 , The heat loss wind speed sensor provided by the present invention includes a glass substrate 1 , a silicon dioxide layer 2 on the front of the glass substrate, a heating inductance coil 3 , and a heating inductance coil 4 . Wherein, the thermal conductivity of the glass substrate 1 can be less than 10; of course, theoretically speaking, there is no requirement for the thermal conductivity of the substrate, but in order to improve the sensitivity, it is better to use glass. The heating inductance coil 3, that is, the heating element, is grown on the silicon dioxide layer 2 on the front side of the glass substrate 1, and the central line end of the heating inductance coil 3 passes through the silicon dioxide layer 2 and is connected to the external line end to form a closed loop , by applying an alternating current to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com