Large cross section submarine optical cable

A submarine optical cable and large cross-section technology, which is applied in the direction of light guides, optics, optical components, etc., can solve the problems of high production costs, unsatisfactory electrical performance of submarine optical cables, and unsuitable for large-length production, etc., to achieve extended life and environmental resistance Adaptable and well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

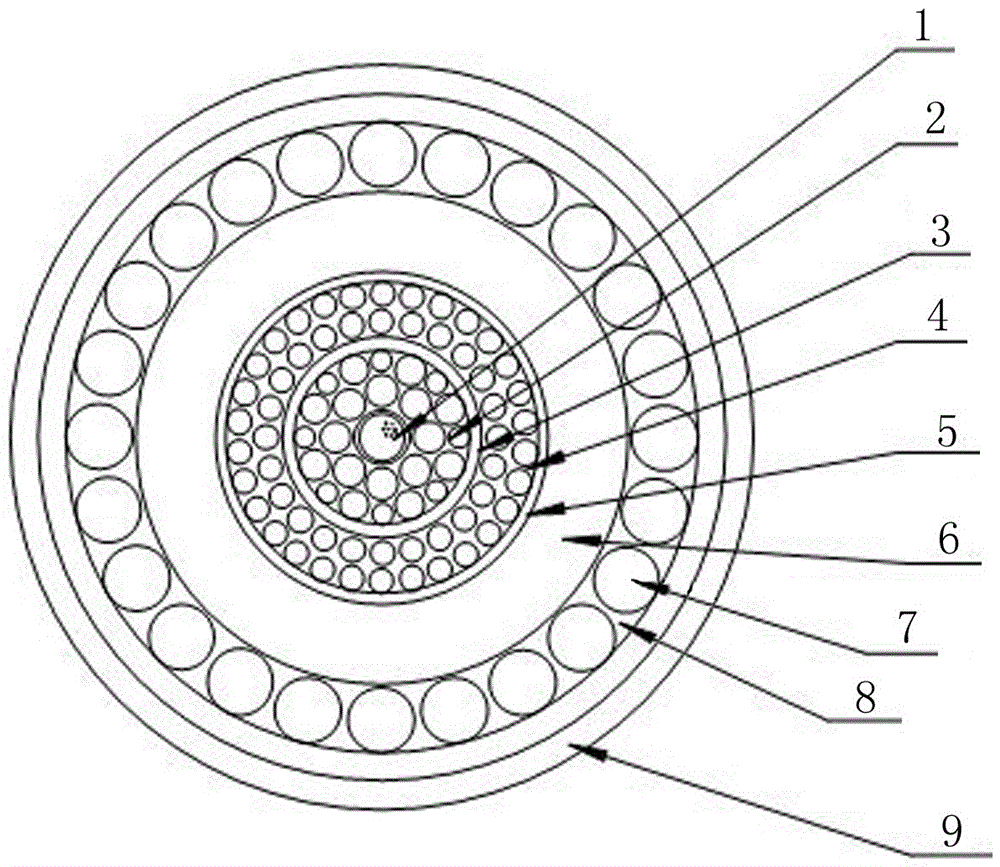

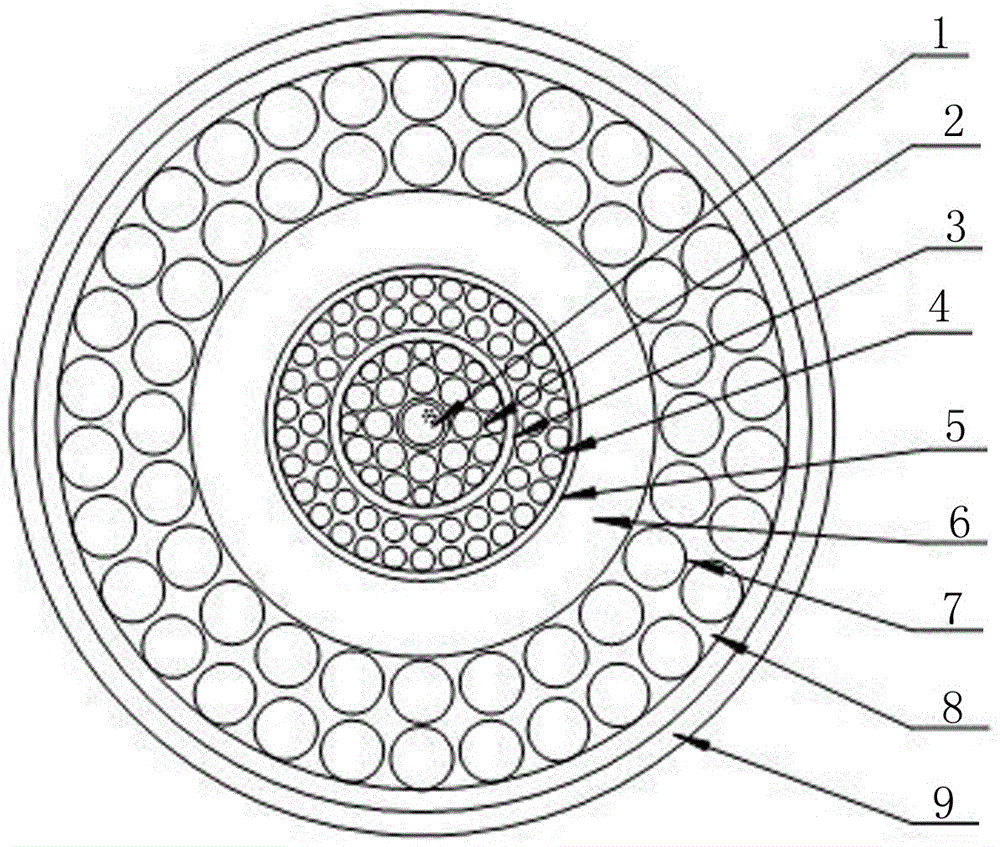

[0018] Such as figure 1 , 2 As shown, a large cross-section submarine optical cable includes an optical cable core and an outer sheath of an optical cable. The optical cable core is composed of a stainless steel optical unit 1, an inner armor wire 2, a copper tube 3, a copper wire 4, a water-blocking material and a shielding layer 5, The insulating sheath 6 is composed of the inner armor wire 2 twisted on the stainless steel optical unit 1, and then wrapped by the copper tube 3, the copper wire 4 is twisted outside the copper tube 3, and the water-blocking material and the shielding layer 5 are wrapped on the copper wire 4 , water-blocking material and shielding layer 5 are covered with an insulating sheath 6, and the outer sheath of the optical cable is composed of outer armored steel wire 7, asphalt 8, and polypropylene rope 9 from the inside to the outside, and the outer armored steel wire 7 is stranded on the insulating sheath 6, the armored steel wire 7 is covered with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com