Liquid metal rheostat

A technology of liquid metal and rheostat, which is applied in the direction of liquid resistors, etc., can solve the problems of increased operation complexity, difficulty in heat dissipation, corrosion of travel switch shell, etc., and achieve the effect of infinite continuous change, normal operation and various setting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

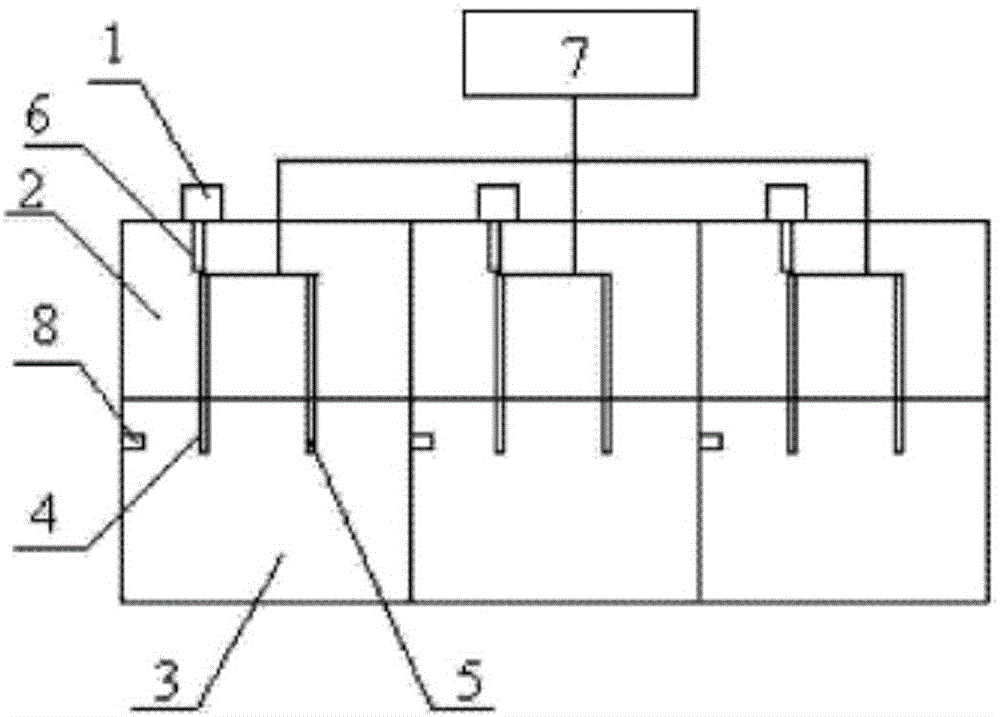

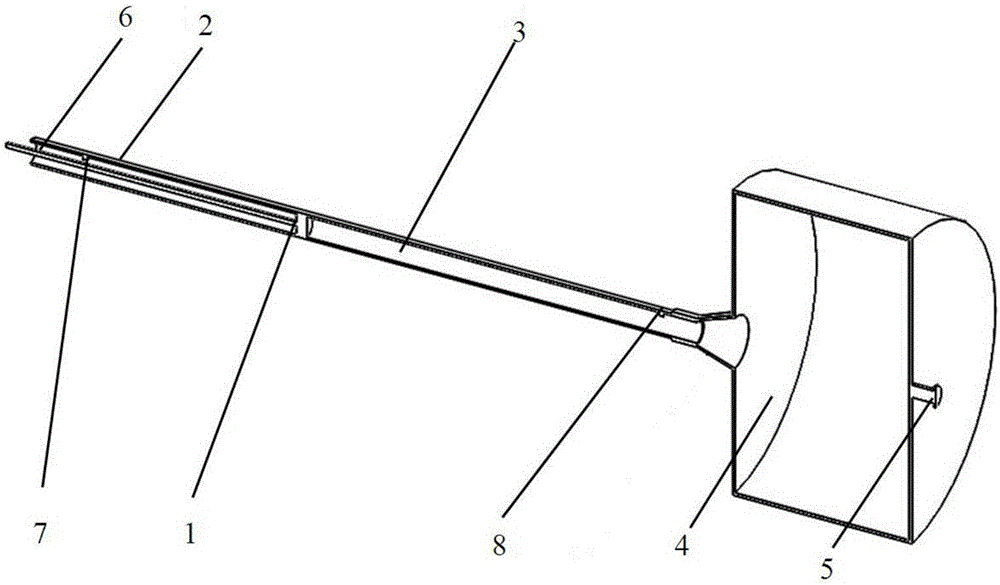

[0027] See figure 2 As shown, a liquid metal varistor includes a pipe 2 and a liquid container 4, the pipe 2 is connected to the liquid container 4, and both the pipe 2 and the liquid container 4 contain the liquid metal 3.

[0028] The pipeline 2 is provided with a conductive movable joint 6 which is used for connecting external wires; the end of the liquid container 4 is provided with a fixed joint 5 which is used for connecting external wires. The movable joint 6 is an iron rod or a copper rod; the fixed joint 5 is connected with the liquid metal 3 in the liquid container 4.

[0029] The movable joint 6 and the fixed joint 5 are used as joints at both ends of the varistor to connect to external wires respectively for connecting the varistor to the circuit.

[0030] The pipe 2 and the liquid container 4 contain the liquid metal 3, and the movable joint 6 and the fixed joint 5 for connecting external wires are respectively provided at both ends; the movable joint 6 can change the r...

Embodiment 2

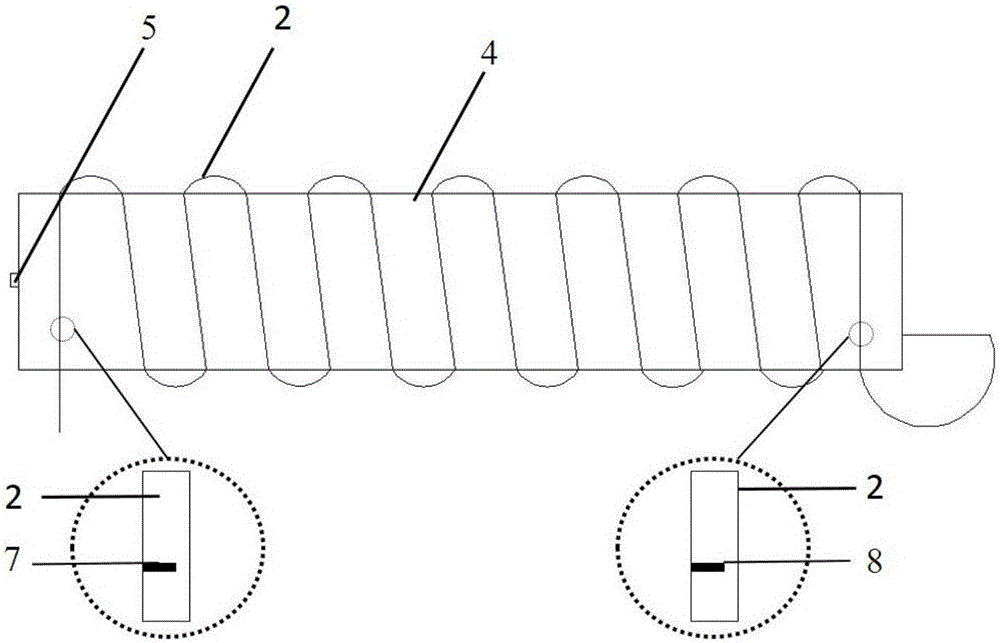

[0070] See image 3 As shown, a liquid metal varistor includes a pipe 2 and a liquid container 4, the pipe 2 is connected to the liquid container 4, and both the pipe 2 and the liquid container 4 contain the liquid metal 3.

[0071] The pipeline 2 is provided with a conductive movable joint 6 which is used for connecting external wires; the end of the liquid container 4 is provided with a fixed joint 5 which is used for connecting external wires. The movable joint 6 is an iron rod or a copper rod; the fixed joint 5 is connected with the liquid metal 3 in the liquid container 4.

[0072] The movable joint 6 and the fixed joint 5 are used as joints at both ends of the rheostat to connect to external wires respectively for connecting the rheostat to the circuit.

[0073] The pipe 2 and the liquid container 4 contain the liquid metal 3, and the movable joint 6 and the fixed joint 5 for connecting external wires are respectively provided at both ends; the movable joint 6 can change the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com