Cleaning and cooling device for silicon wafer before printing in solar battery cell preparation process

A technology of solar cell and preparation process, applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of easy residual foreign matter and poor cleaning effect on silicon wafers, and achieves favorable heat dissipation and reduces punctured damage. Probability, the effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

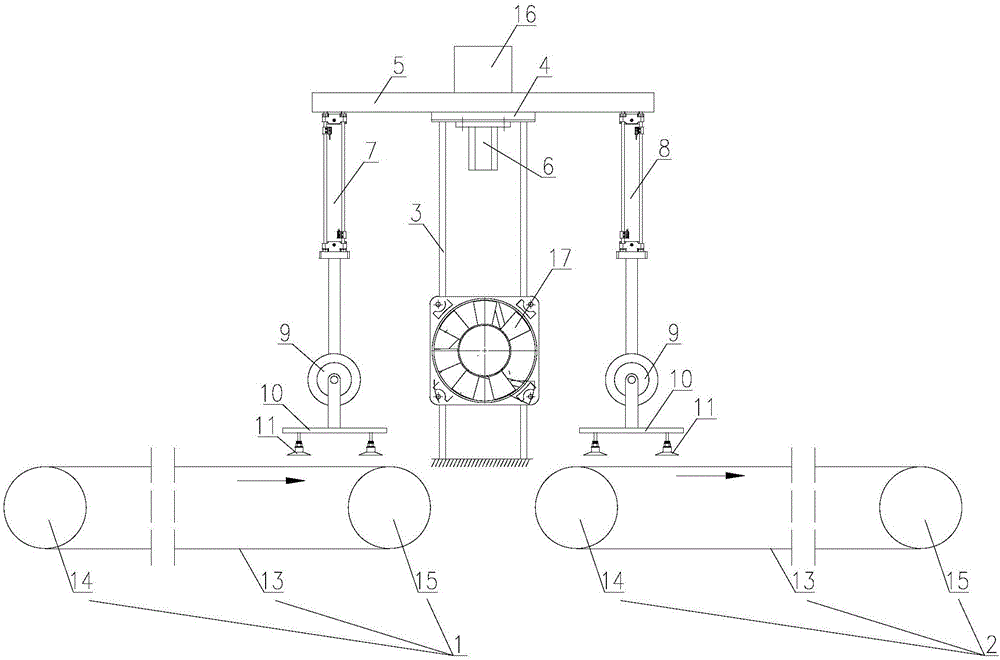

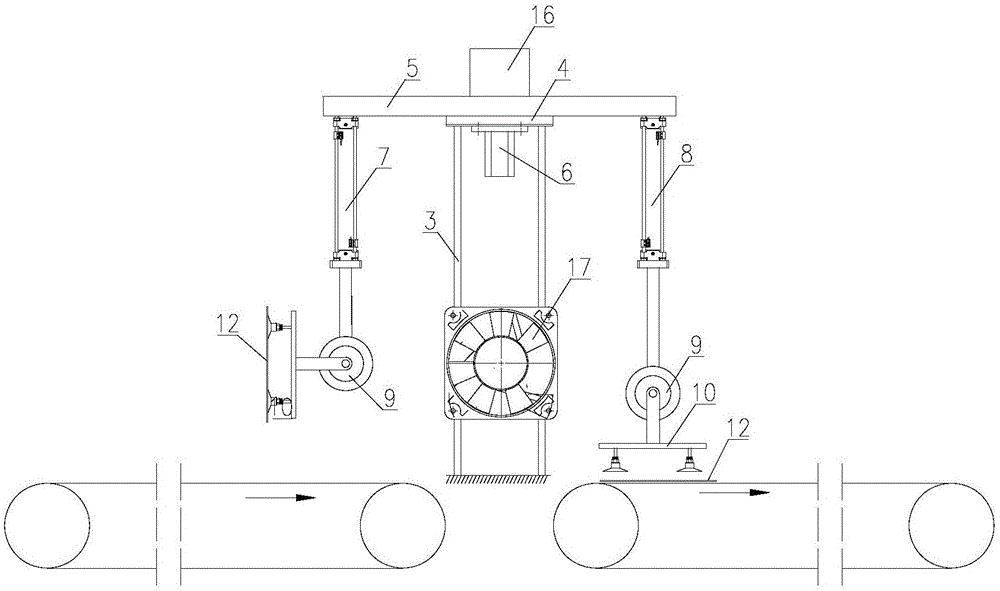

[0016] Such as figure 1 and 2 As shown, a device for cleaning and cooling silicon wafers before printing in the solar cell production process includes a first belt conveyor 1 and a second belt conveyor 2, and the first belt conveyor 1 and the second belt conveyor 2 are arranged between There is a bracket 3, a platform 4 is arranged on the top of the bracket 3, a turntable 5 is rotatably connected to the platform 4, a motor 6 is fixed on the lower surface of the platform 4, the output end of the motor 6 is fixedly connected with the turntable 5, and the lower surface of the turntable 5 is arranged symmetrically There are a first cylinder 7 and a second cylinder 8, the extending ends of the first cylinder 7 and the second cylinder 8 face downward, and the extending ends of the first cylinder 7 and the second cylinder 8 are fixed with a rotary cylinder 9, and the rotary cylinder 9 is fixed with pole 10 on the output end, and the lower surface of pole 10 is fixed with some sucker...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com