A hybrid laser for polymer-assisted bonding and its preparation method

A technology of lasers and polymers, applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of restricting the development of III-V lasers, unsuitable laser light sources, and low luminous efficiency, so as to shorten the bonding process time, High maneuverability and high viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

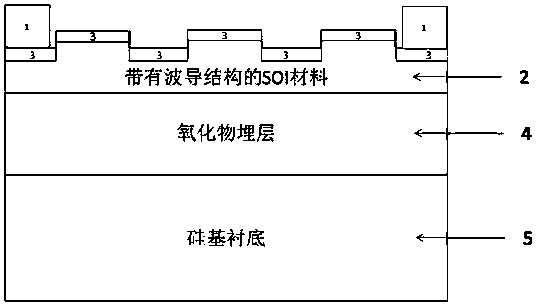

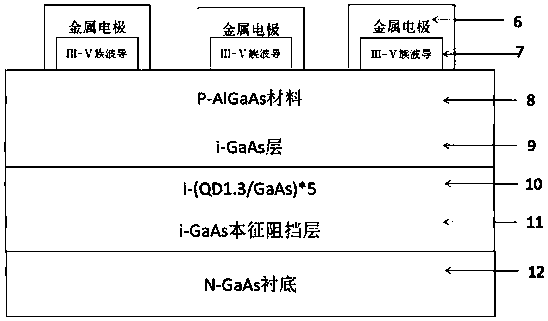

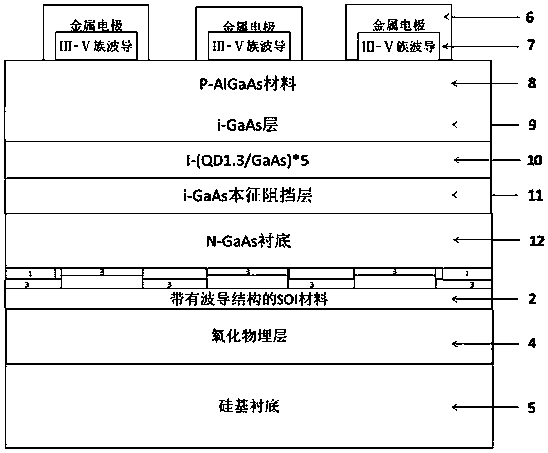

[0029] The invention proposes a polymer-assisted bonding III-V group laser and a silicon-based waveguide micro-cavity hybrid laser and its preparation method. The insulating polymer material is used instead of metal as the auxiliary bonding material to avoid device failure. conduction between. Making the silicon waveguide blocking structure can make the air gap exist between the silicon waveguides, which can assist the device to dissipate heat, and avoid the influence of device performance caused by device heating after power-on. The polymer material PVA is soluble in water, non-polluting, insoluble in acetone, alcohol and other organic solvents, and can be cured at low temperature to form a high-viscosity bond. Device o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com